Non-powered nose hair trimmer and preparation method thereof

A manufacturing method and trimmer technology, which can be used in clothing, metal processing, hairdressing equipment, etc., can solve the problems of difficult cutting, uncomfortable users, and inconvenient use, so as to reduce the difficulty of the overall processing technology and improve nose hair. Cutting efficiency and the effect of reducing the manufacturing defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

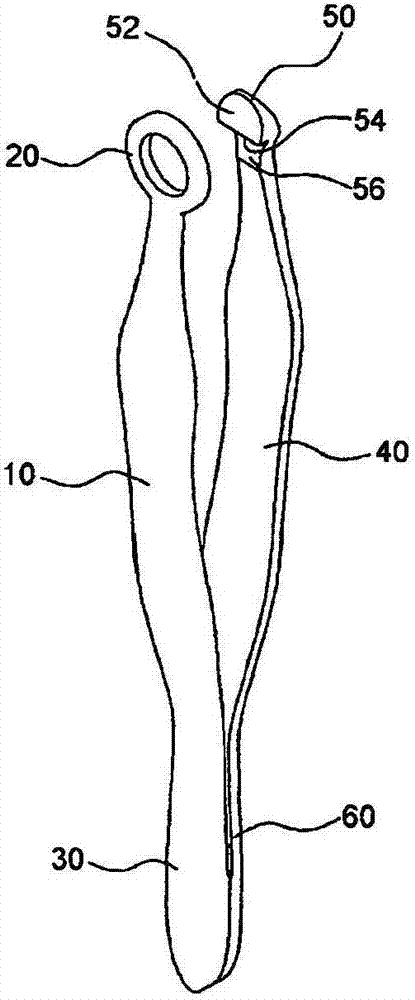

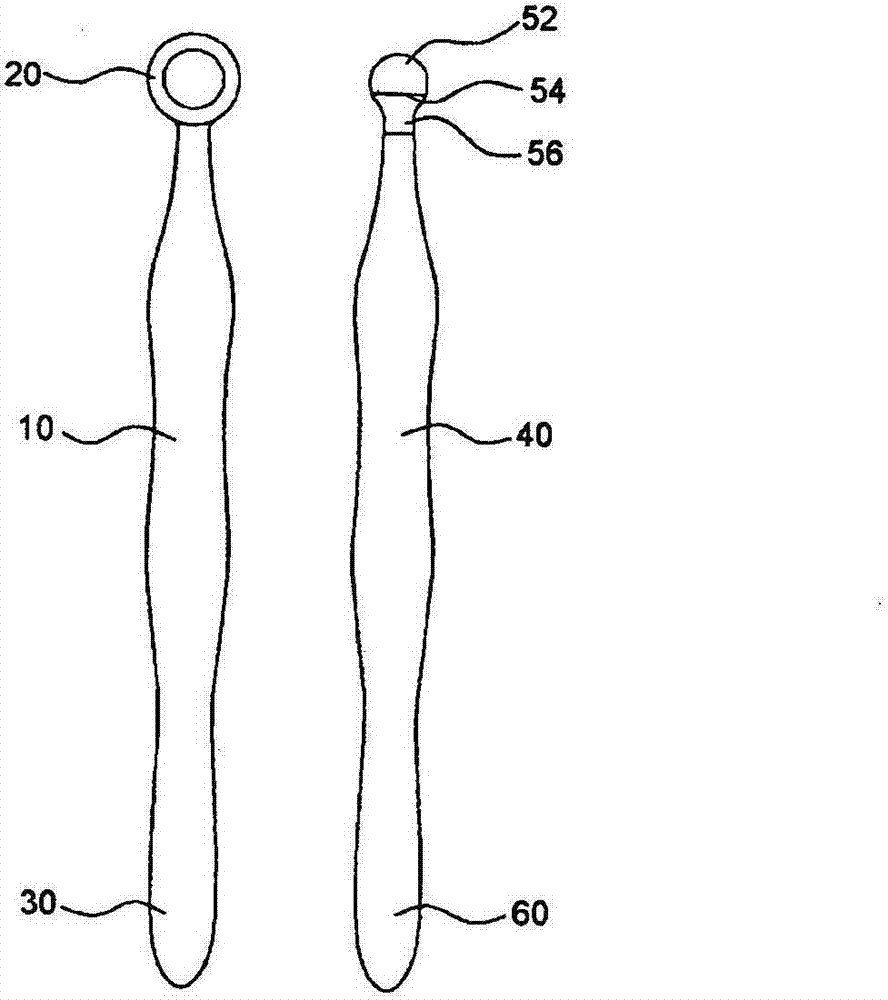

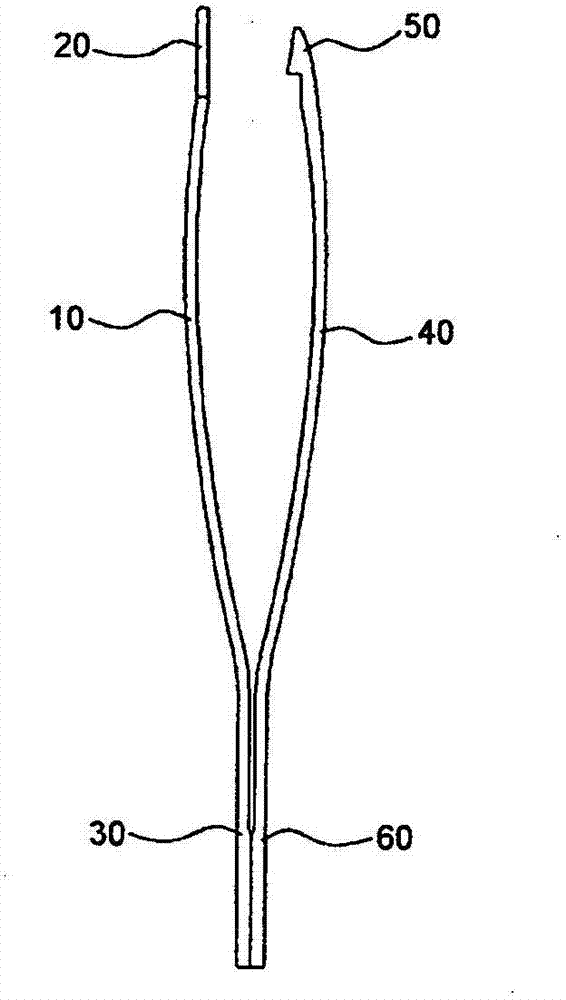

[0047] The constitution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0048] It should be mentioned here that the interpretation of the terms used in this specification and claims should not be limited to the meaning of the dictionary, and the inventor can properly define the concepts of related terms in order to use the best method to explain his invention. Based on this principle, this The terms or words used in the specification and claims should be interpreted according to the meaning and concept of the technical idea of the present invention.

[0049] Therefore, the embodiments described in this specification are only preferred embodiments of the present invention and cannot summarize all the technical ideas of the present invention, and there may be various equivalents and modified examples that can be replaced when the patent application of the present invention is filed.

[0050] The non-electric nose hair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com