Bonded permanent magnet for large direct-drive permanent-magnet generator

A permanent magnet generator, permanent magnet technology, applied in the direction of magnetic circuit shape/style/structure, layered products, metal layered products, etc., can solve the problems of irreversible demagnetization of permanent magnets, damage to generator performance, etc., to reduce heat , The effect of reducing surface eddy current and excellent insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

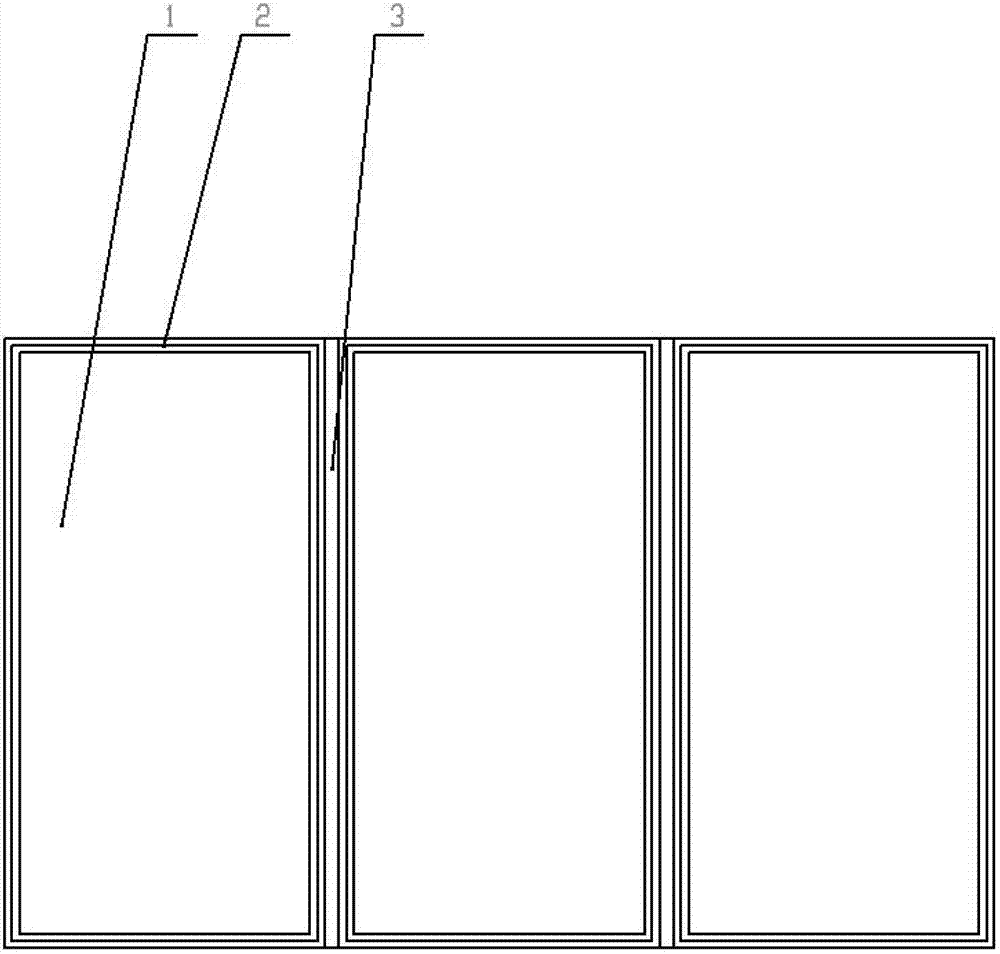

[0017] see figure 1 As shown, a bonded permanent magnet for a large direct-drive permanent magnet generator of the present invention is formed by bonding a plurality of small permanent magnets 1 .

[0018] Furthermore, the outer surface of each small permanent magnet 1 is provided with nickel-copper plus epoxy coating 2, that is, the surface of the permanent magnet 1 is first coated with a layer of nickel-copper alloy coating, and after the nickel-copper alloy coating is coated, another layer of ring is added. Oxygen coating, two coatings with different properties can ensure that the permanent magnet has good salt spray resistance, heat and humidity resistance and anti-corrosion performance, and better guarantee the operating life of the permanent magnet generator.

[0019] The small permanent magnets 1 after coating are bonded by epoxy glue 3. The curing characteristics of epoxy glue 3 can ensure the high shape tolerance and dimensional tolerance of each group of permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com