High energy density charge-discharge lithium battery

A high energy density, charge and discharge technology, applied in the field of electrochemistry, can solve the problems of low energy density, poor safety performance, high production cost and other problems of lithium-ion batteries, and achieve excellent stability and cycle performance, high energy effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

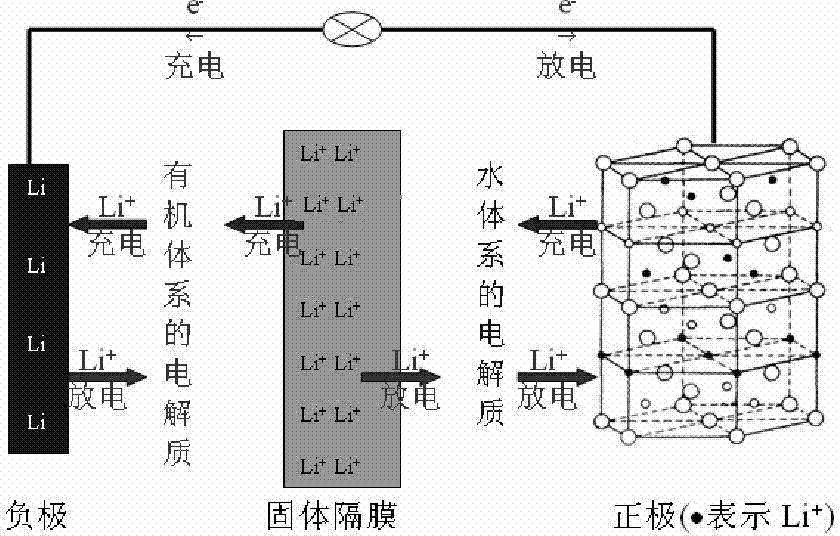

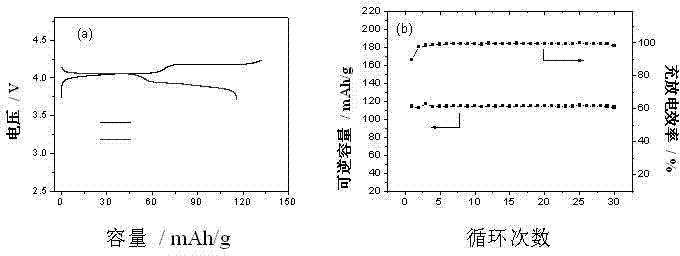

[0027] 0.1mg / cm 2 The platinum sheet of lithium gallium alloy is the negative electrode, and LiCoO with a reversible capacity of 145 mAh / g 2 It is the active material of the positive electrode, the conductive agent, the binder, and the solvent are the same as those of Comparative Example 1. After being stirred into a uniform slurry, it is coated on a stainless steel mesh to form a positive electrode piece. Take the component as 19.75Li 2 O-6.17Al 2 O 3 -37.04GeO 2 -37.04P 2 O 5 (Lithium-containing inorganic oxide) The ceramic membrane is a separator, the negative side is an organic electrolyte (Zhangjiagang Guotai Huarong’s LB315), and the positive side is 1 mol / l LiNO 3 Solution. After sealing, get LiCoO 2 It is a charge-discharge lithium battery with a positive electrode and a lithium gallium alloy as the negative electrode. At 0.1 mA / cm 2 The current is tested, and the charge is 0.1 mA / cm 2 Perform constant current charge, charge to 4.25 V; discharge current is 0.1 mA / c...

Embodiment 2

[0031] The aluminum foil with LiAl alloy formed on the surface is used as the negative electrode, and LiNiO with a reversible capacity of 180 mAh / g 2 It is the active material of the positive electrode, the conductive agent, the binder, and the solvent are the same as those of Comparative Example 1. After being stirred into a uniform slurry, it is coated on a stainless steel mesh to form a positive electrode piece. The component is Li 1.5 Al 0.5 Ge 1.5 P 3 S 12 (Lithium-containing sulfide) The ceramic membrane is a separator, and the negative electrode side is an organic electrolyte (0.8 mol / l LiBOB electrolyte dissolved in a 1:1 mass ratio of ethylene carbonate and methyl ethyl carbonate mixed solvent), The positive side is 1 mol / l CH with 1 wt.% polyvinyl alcohol dissolved 3 COOLi gel. After sealing, get LiNiO 2 A charge-discharge lithium battery with positive electrode and lithium aluminum alloy as negative electrode. The test conditions are the same as in Example 1. A...

Embodiment 3

[0035] LiMn with a reversible capacity of 115 mAh / g with metallic lithium as the negative electrode 2 O 4 It is the active material of the positive electrode, the conductive agent, the binder, and the solvent are the same as those of Comparative Example 1. After being stirred into a uniform slurry, it is coated on a stainless steel mesh to form a positive electrode piece. Take the component as 0.75Li 2 O-0.3Al 2 O 3 -0.2SiO 2 -0.4P 2 O 5 -0.1TiO 2 (Lithium-containing inorganic oxide) The ceramic membrane is a separator, and the negative side is a composite membrane PVDF / PMMA / PVDF composed of a gel polymer electrolyte (porous polyvinylidene fluoride (PVDF) and polymethyl methacrylate (PMMA)). Organic electrolyte (composed of LB315 from Zhangjiagang Guotai Huarong), 0.5 mol / l Li on the positive side 2 SO 4 Aqueous electrolyte. After sealing, get LiMn 2 O 4 A charge-discharge lithium battery with positive electrode and metal lithium as negative electrode. The test conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com