Halogen-free fire-retardant unsaturated polyester resin, preparation method and use thereof

A polyester resin, unsaturated technology, applied in the field of substituted alkanes, to achieve the effect of overcoming brittleness, low toxicity, flame retardancy, and reducing brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

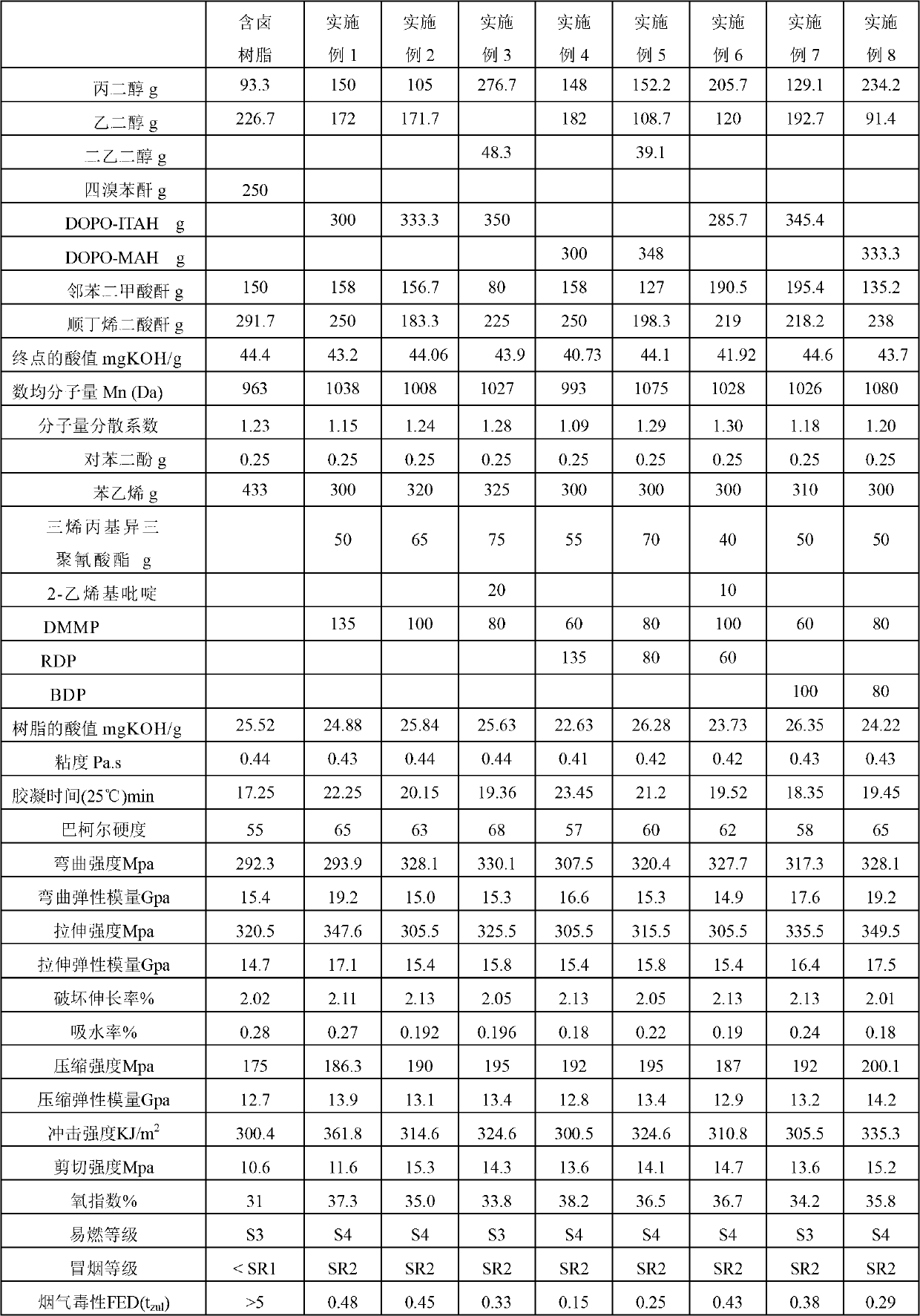

Embodiment 1

[0032]Add 150g of 1,2-propanediol, 172g of ethylene glycol, 300g of DOPO grafted with itaconic acid (DOPO-ITAH), 158g of ortho-benzene Diformic anhydride and 250g maleic anhydride; after the water is discharged at 155°C-160°C, keep it at 155°C-160°C for 2 hours. After the heat preservation is over, slowly increase the oil temperature until the material temperature is 175°C-180°C. Control the temperature of the distillation head at 97°C-100°C, and when the distillation temperature is lower than 80°C, go to the fractionation column. During the reaction process, take a sample to measure the solid acid value. When the solid acid value is 39-45mgKOH / g, start to cool down and add 0.25g hydroquinone to it to obtain a halogen-free flame-retardant unsaturated polyester (Mn is 1038Da, dispersed coefficient of 1.15). When the temperature drops to 160°C, pour the polyester into a dilution barrel previously filled with 300g styrene and 50g triallyl isocyanurate, stir evenly and cool down ...

Embodiment 2

[0034] Add 105g of 1,2-propanediol, 171.7g of ethylene glycol, 333.3g of DOPO grafted with itaconic acid (DOPO-ITAH), 156.7 g phthalic anhydride and 183.3g maleic anhydride; after the water is discharged at 155°C-160°C, keep it at 155°C-160°C for 2 hours, after the heat preservation is over, slowly increase the oil temperature until the material temperature is 175°C-180 ℃, the temperature of the distillation head is controlled at 97-100℃ during the reaction process, and when the distillation temperature is lower than 80℃, the fractionation column is removed. During the reaction process, take a sample to measure the solid acid value. When the solid acid value is 39-45mgKOH / g, start to cool down and add 0.25g hydroquinone to it to obtain a halogen-free flame-retardant unsaturated polyester (Mn is 1008Da, dispersed coefficient of 1.24). When the temperature drops to 160°C, pour the polyester into a dilution barrel previously filled with 320g styrene and 65g triallyl isocyanurate...

Embodiment 3

[0036] Add 276.7g propylene glycol, 48.3g diethylene glycol, 350g itaconic acid grafted DOPO (DOPO-ITAH), 80g o-phthalic acid Diformic anhydride and 225g maleic anhydride; after the water is discharged at 155°C-160°C, keep warm at 155°C-160°C for 2 hours. After the heat preservation is over, slowly increase the oil temperature until the material temperature is 175°C-180°C. Control the temperature of the distillation head at 97°C-100°C, and when the distillation temperature is lower than 80°C, go to the fractionation column. During the reaction process, take a sample to measure the solid acid value. When the solid acid value is 39-45mgKOH / g, start to cool down and add 0.25g hydroquinone to it to obtain a halogen-free flame-retardant unsaturated polyester (Mn is 1027Da, dispersed coefficient of 1.28). When the temperature drops to 160°C, pour the polyester into a dilution barrel previously filled with 325g of styrene and 75g of triallyl isocyanurate, stir evenly and cool down t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com