Small thermal conduction heating head

A heat conduction and heating head technology, which is applied in the field of mechanical processing, can solve the problems of reduced reliability and efficiency, small heating area of heating plate, and small number of heating nuts, etc., so as to achieve no redundant mechanical action, increase production efficiency, and simplify structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

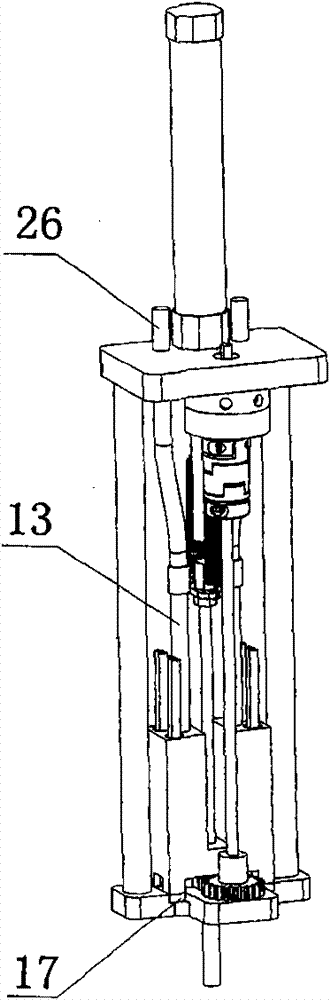

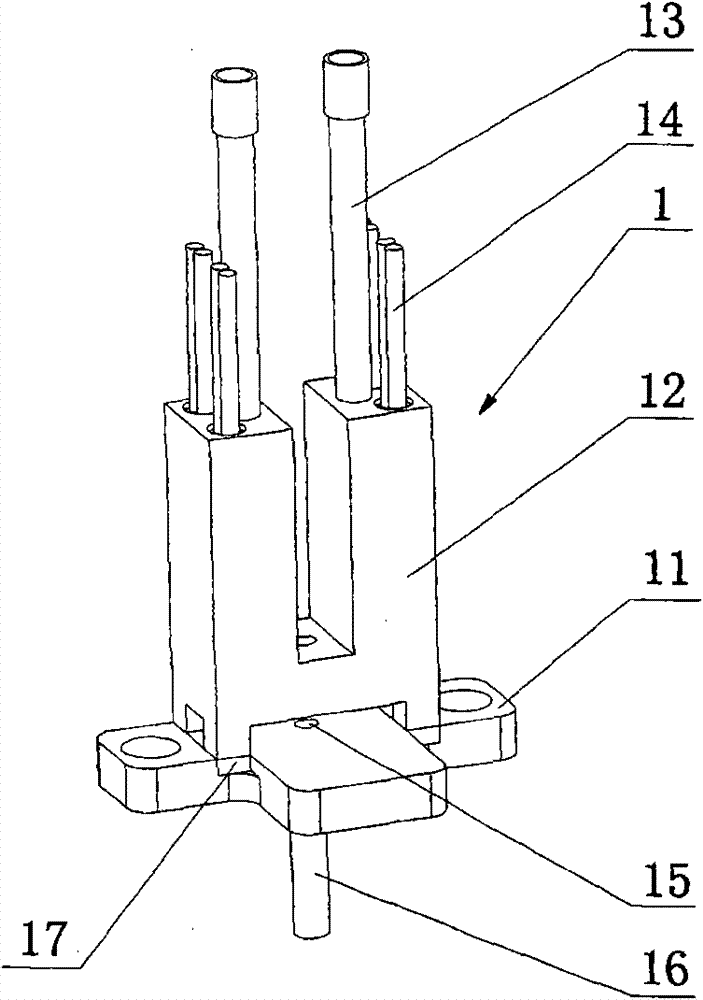

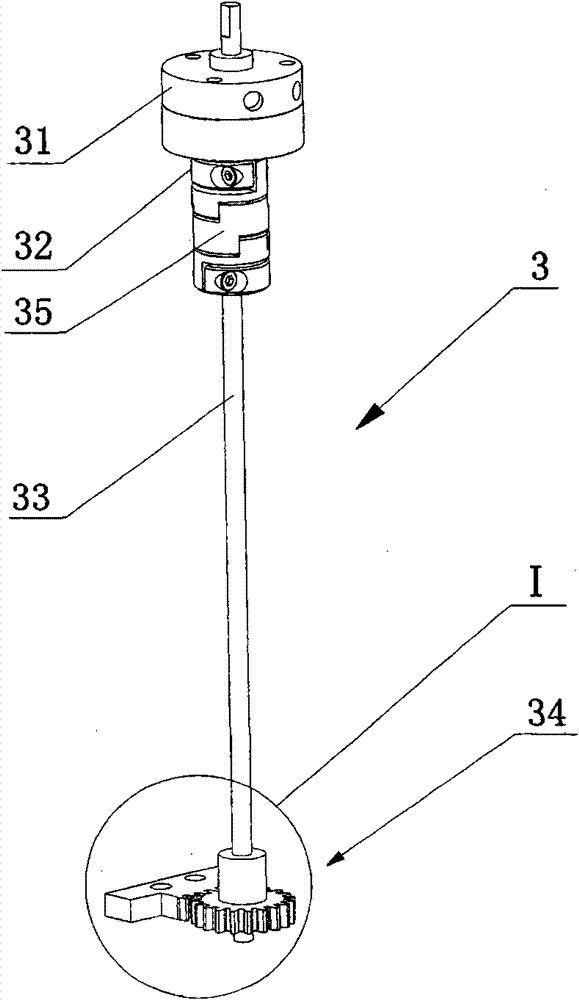

[0024] Such as figure 1 , 2 , 3, 4, 5, and 6, a small heat conduction heating head includes a feeding heating part 1, a blanking and pressing part 2 and a reciprocating distribution part 3,

[0025] The feeding heating part 1 is composed of a base 11, a plurality of heating cabins 12 arranged on the base 11, a feeding pipe 13 connecting the heating cabins 12 and feeding them, and a heating component providing a heat source for the heating cabin 12. The heating components adopt Electric heating rods 14, electric heating rods 14 are plugged in the heating chamber 12 around the inner cavity of the heating chamber 12 along the length direction of the three-dimensional heating cabin 12, in order to improve its heating efficiency and shorten the heating time, several electric heating rods 14 can be provided. The base 11 is provided with a through bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com