Automatic pipe end thread sandblasting machine

A technology of pipe end threads and sand blasting machines, which is applied in the field of sand blasting machines, can solve the problems of seamless steel pipe product quality, increase product cost, etc., improve anti-sticking and anti-corrosion performance, increase pass rate, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

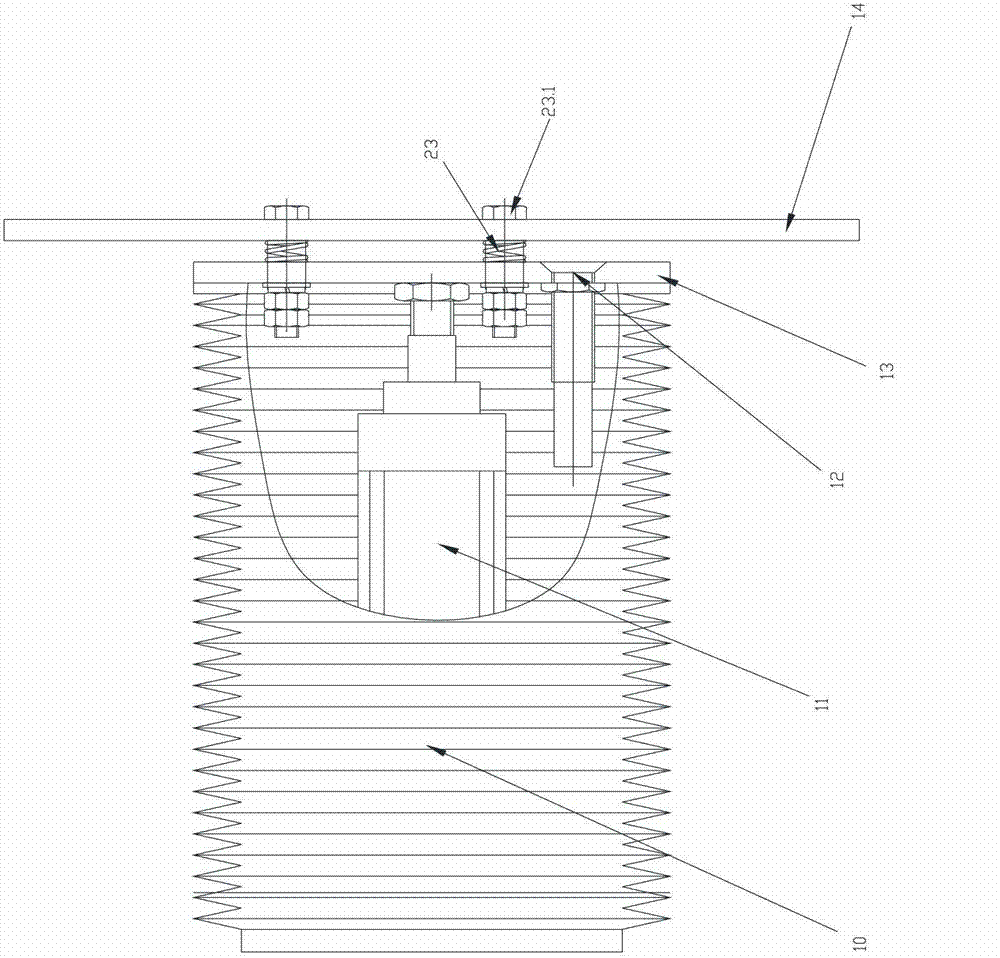

[0026] The structure and working process of the automatic pipe end thread sand blasting machine of the present invention will be described in conjunction with the accompanying drawings.

[0027] The structure of the automatic pipe end thread sandblasting machine of the present invention is: the sandblasting machine includes a mechanical part, a pneumatic part and an electrical control part.

[0028] The mechanical part: this part includes a sandblasting room, a dust removal room, a chassis and guide rails; the sandblasting room includes a box body 24 and a sealing port 21 opened in front of the box body, and the upper part of the box body 24 is sandblasting The lower part is the sand storage box 24.2, the control valve island 19 set on the upper part of the box body 24 and the inner inverted sandblasting cylinder 15 arranged at the middle and rear, the cylinder rod of the inner inverted sandblasting cylinder 15 passes through the box body 24, and is connected with the first A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com