Tourmalinite-containing composite methane catalyst

A catalyst, tourmaline technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, gas fuels, etc., to achieve the effects of reduced agglomeration, rational use of energy saving and emission reduction, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) According to the molar ratio La:Ce:Co:Mn=9:1:5:5, weigh La(NO 3 ) 3 ·6H 2 O 16.30g, Ce(NO 3 ) 3 ·6H 2 O 1.80g, Co(NO 3 ) 2 ·6H 2 O 6.03g, mass concentration 50%Mn(NO 3 ) 2 Solution 7.34g (total metal molarity is 0.0817mol);

[0049] (2) Dissolve the nitrate weighed in the previous step in 60ml of deionized water, add 20.8g (0.098mol) of citric acid, and stir at room temperature for 1 hour to mix the ingredients evenly;

[0050] (3) Heat and stir in a water bath (80°C), the water evaporates continuously, gradually forming a sol, and continue stirring until the color of the colloid becomes darker, forming a wet gel;

[0051] (4) Let the wet gel treated in step (4) stand for 12 hours, dry and grind to obtain dry gel;

[0052] (5) The material was placed in a muffle furnace, roasted at 800° C. for 5 hours, cooled and then ground to obtain 10 grams of perovskite-type methane catalytic material. Exist in the form of composite oxide pairs La 0.9 Ce 0.1 co 0....

Embodiment 2

[0054] The difference between this embodiment and Example 1 is that 0.2 g of tourmaline (2.74 μm) (produced by Henan Xixia Company) was added after adding citric acid in step (2), and stirred at room temperature for 1 hour to obtain a mixed solution. Other steps and parameters are the same as in Example 1. Tianjin Xianquan Industry and Trade Development Co., Ltd. WFS3015 catalyst evaluation device.

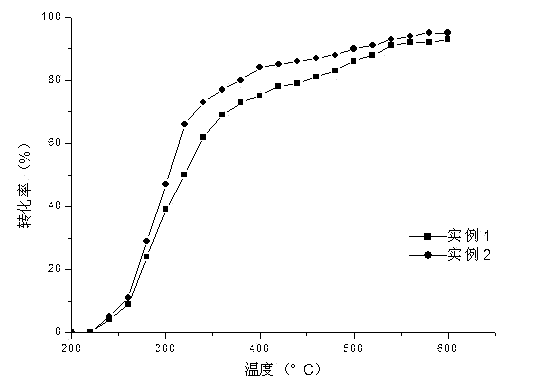

[0055] attached by figure 1 Comparative example 1, 2 samples, the sample catalytic activity after adding tourmaline is higher, and methane light-off temperature reduces 15 ℃, and complete conversion temperature advances 25 ℃, thus can find out that adding tourmaline sample can effectively improve catalytic material catalysis Oxidation of methane activity.

Embodiment 3

[0057] The difference between this embodiment and Example 1 is that the Ce(NO 3 ) 3 ·6H 2 O is replaced by Sr(NO 3 ) 2 . Other steps and parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com