Connecting and sealing structure of oral implant-base

An oral implant and sealing structure technology, applied in dental implants, medical science, dentistry, etc., can solve problems such as soft tissue and bone tissue cannot exist stably for a long time, blood vessels cannot grow in, soft tissue inflammation, etc., to avoid cortical bone atrophy and Microbial growth, reducing bone stress concentration and shielding, alleviating the effect of neck stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

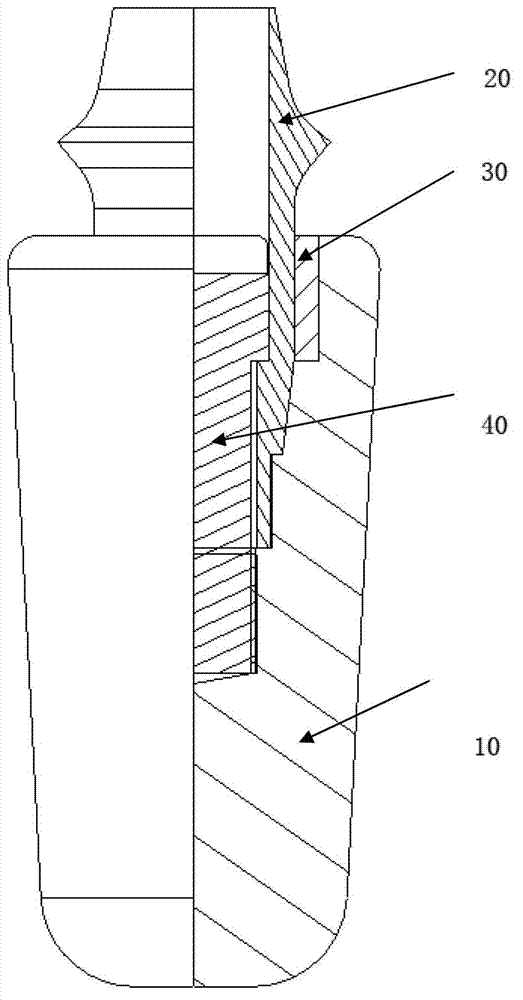

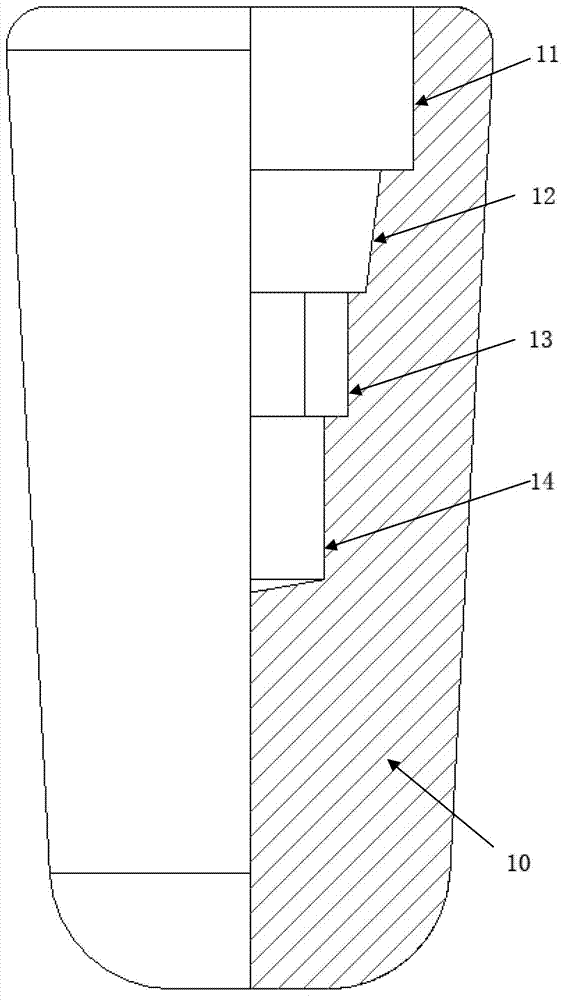

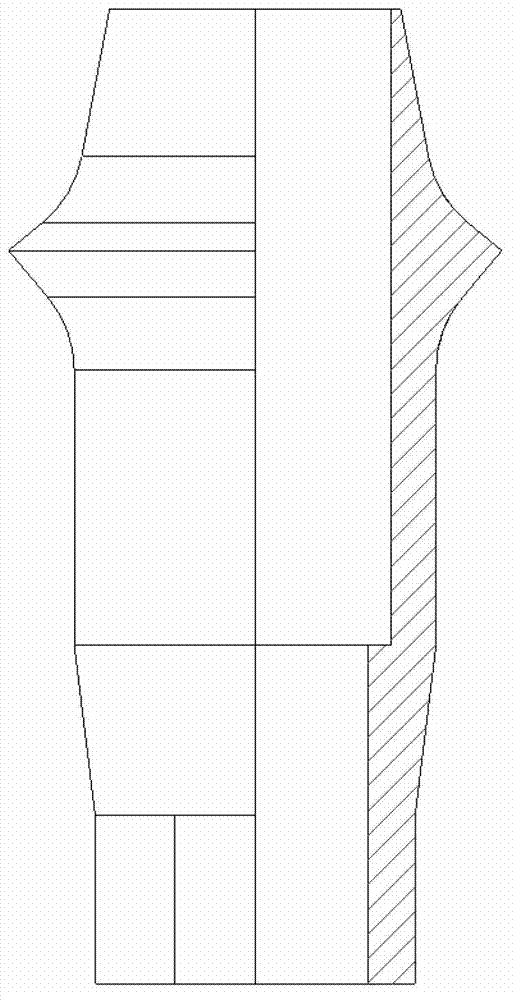

[0019] The present invention is a novel oral implant-abutment connection and sealing structure. The neck of the implant 10 is provided with an upper cylindrical hole 11, a middle conical hole 12, a positioning hole 13, and a lower threaded hole 14; the upper cylindrical hole 11 A sealing ring 30 with a thickness of 0.1-0.5mm is provided between the abutment 20; the height of the sealing ring 30 is 0.5-5mm. The abutment 20 and the implant are connected by a connecting screw 40 . The sealing ring is made of biomedical polymer material. The elastic modulus of the biomedical polymer material is 1-1000Mpa. The biomedical polymer material is polytetrafluoroethylene, silicon rubber or natural rubber. The cone angle of the conical hole 12 in the middle section is 2°51′26″˜3°00′53″.

[0020] The present invention is provided with sealing ring between implant body and abutment, and this sealing ring has brought following effect:

[0021] (1) The medical polymer material used in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com