Spray nozzle and method for atmospheric spraying, device for coating, and coated component

A nozzle and coating technology, applied in the field of components, can solve the problems of high cost, lack of flexibility of the adhesion-enhancing layer, and vacuum method consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The description and drawings illustrate only embodiments of the invention.

[0015] exist figure 1 The spray head 1 is shown in . The spray head 1 has conventional nozzles 4 and attachments 19 known from the prior art regarding plasma shower heads (APS, . . . ). Parallel to the longitudinal direction 26 of the inner channel 22 of the nozzle 4 , the at least partially melted coating material heated by the plasma flows from the nozzle 4 in an outflow direction 25 . The plasma is generated in the inner channel 22 of the nozzle 4 .

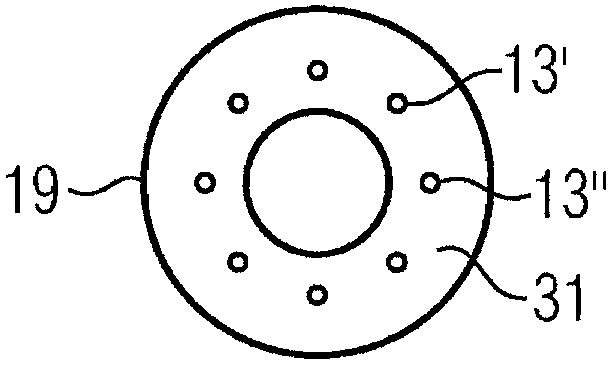

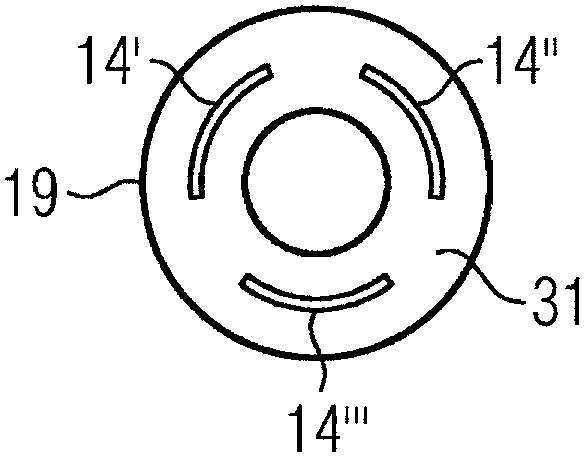

[0016] The nozzle 4 is only modified in that the attachment 19 can be fixed on the nozzle. Attachment 19 extends the inner channel of nozzle 4 . The shielding gas 28 passes through holes 13, 13 ', 13 " (see also figure 2 , 3 ) flows out, and the desired geometry of the shielding gas shield is created around the outflowing cladding material. Shielding gas 28 also can flow out from slit 14 ', 14 ", and described slit is arranged in circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com