Special nozzle of gas stove

A gas stove and special-shaped technology, which is applied in the field of gas stoves, can solve the problems of low efficiency and difficult installation, and achieve the effect of improving combustion efficiency and increasing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

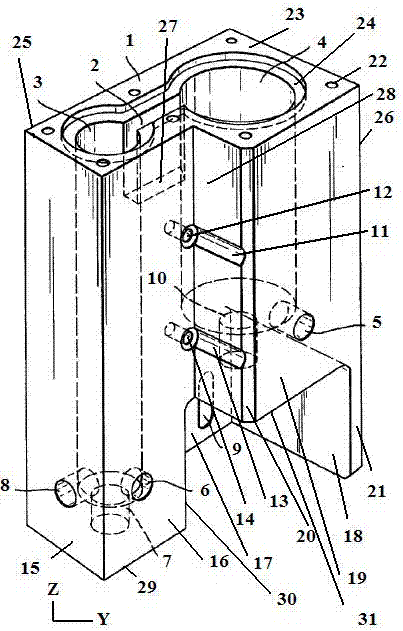

[0018] by figure 1 Take the angle of view in , as an example, a special-shaped nozzle for a gas stove, the upper cross-sectional surface of which is L-shaped, the special-shaped nozzle for a gas stove includes a special-shaped body 1, and the special-shaped body 1 includes a first left side 15, a first front side 16. The second left side 28, the second front side 19, the first right side 26, the first top 23, the first rear side 25, the first bottom 29, the width of the first left side 15 is less than The width of the first right side 26 (take the direction Y perpendicular to the vertical direction Z in the figure as the width direction), the difference between the width of the first left side 15 and the width of the first right side 26 is the second The width of the left side 28, wherein the bottom of the special-shaped body 1 is provided with a groove, and the groove includes the right side 18 of the groove, the top surface 31 of the groove, the rear side 17 of the groove, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com