Device with frictional contact and method for operating a device with frictional contact

A technology of friction contact and contact body, which is applied in the direction of lubricating parts, engine lubrication, shafts and bearings, etc., to achieve high efficiency, long service life and less failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

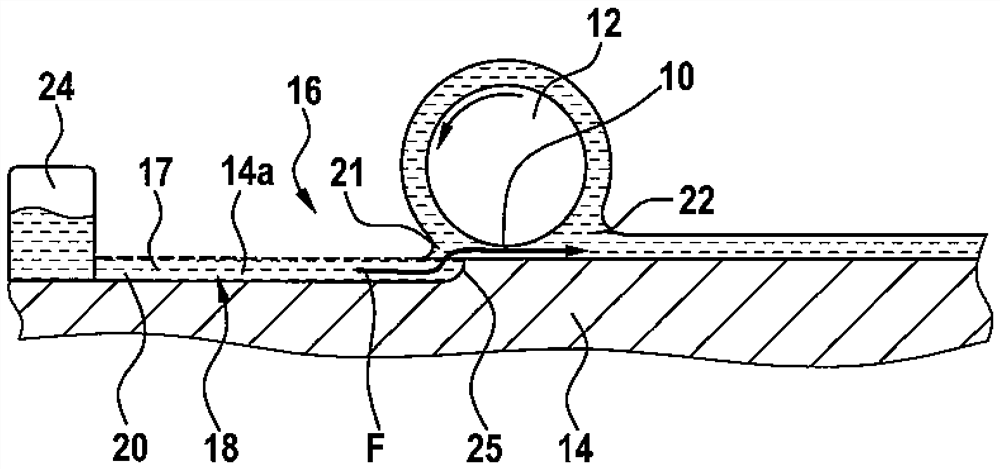

[0024] figure 1 A cross-sectional view of a friction contact according to a preferred embodiment of the invention is shown. The device 1 preferably has a friction contact 10 with a first contact body 12 and a second contact body 14 . The first contact body 12 is preferably adjustable relative to the second contact body 14 . The relative movement of the first contact body 12 relative to the second contact body 14 is rotational in this embodiment. Alternatively, the relative movement of the first contact body 12 relative to the second contact body 14 can eg be translational.

[0025] The first contact body 12 preferably has a substantially circular cross section. Alternatively, the first contact body 12 can, for example, have another suitable cross-sectional shape.

[0026] The second contact body 14 preferably has a substantially planar cross section. Arranged adjacent to the friction contact 10 is a lubricant path 16 leading to the friction contact 10 for supplying the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com