All-lead liquid flow battery

A technology of flow battery and lead liquid is applied in the fields of electrochemical engineering and industrial devices to achieve the effects of increasing the speed of material transfer, simple preparation route and process, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

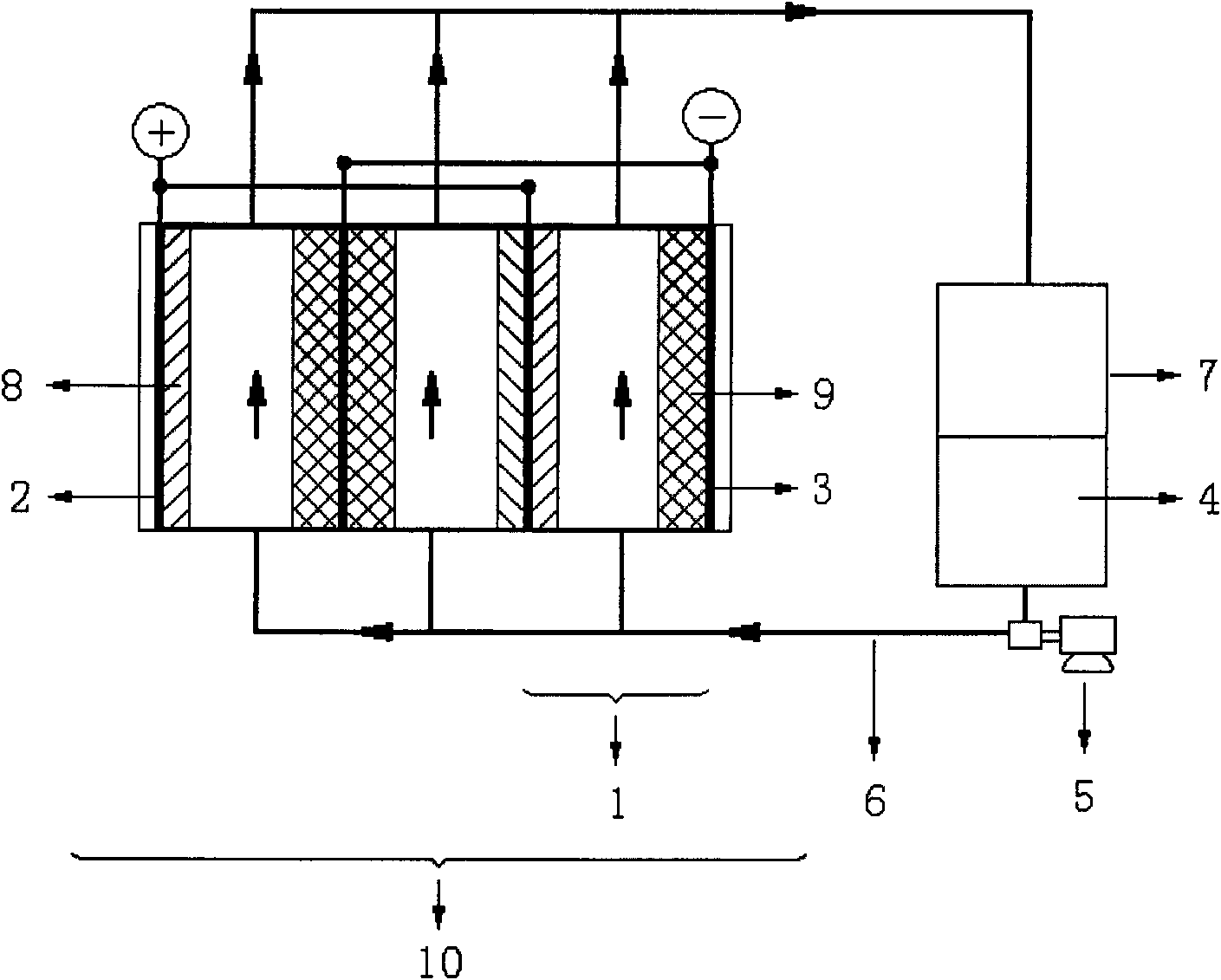

[0020] Such as figure 1 A 3mm thick high-density graphite plate is used as the positive electrode collector and the negative electrode collector are separated and fixed in the plastic case to form an all-lead flow battery monomer. The aqueous solution is stored in polyethylene tanks as the electrolyte, and a silicone tube is used as the pipeline, and a magnetic pump is used to push the electrolyte to flow across the opposite surfaces separating the positive and negative collectors. When charging, the divalent lead ions in the electrolyte are deposited as lead dioxide on the positive electrode collector, and as metallic lead on the negative electrode collector. When discharging, the lead dioxide and metallic lead dissolve into divalent lead ions and enter the electrolyte. at 20mA / cm 2 The current density can be charged and discharged, the current efficiency can reach more than 95%, and the energy efficiency is about 82%.

Embodiment 2

[0022] Such as figure 1 , 0.1mm thick tantalum foil with tantalum carbide film on the surface is used as the positive electrode collector, 0.1mm thick stainless steel foil is used as the negative electrode collector, the positive electrode collector and the negative electrode collector are separated and fixed in the plastic case to form an all-lead flow battery cell . An aqueous solution of 1.0 moles per liter of lead tetrafluoroborate and 1.0 moles per liter of tetrafluoroboric acid is stored in a polyethylene tank as the electrolyte, and a rubber hose is used as a pipeline, and a magnetic pump is used to push the electrolyte to flow through the positive collector and the negative collector Separate opposing surfaces. at 40mA / cm 2 The current density can be charged and discharged, the current efficiency can reach more than 98%, and the energy efficiency is about 75%.

Embodiment 3

[0024] Such as figure 1 A 0.1mm thick titanium foil with a titanium nitride film on its surface is used as the positive electrode collector, and a 0.1mm thick steel foil is used as the negative electrode collector. The positive electrode collector and the negative electrode collector are separated and fixed in a plastic case to form an all-lead flow battery cell body. The aqueous solution of 1.0 moles per liter of lead tetrafluoroborate and 1.5 moles per liter of tetrafluoroboric acid is stored in a polyethylene tank as the electrolyte, and the rubber hose is used as the pipeline, and a magnetic pump is used to push the electrolyte to flow through the positive collector and the negative collector. Separate opposing surfaces. at 10mA / cm 2 The current density can be charged and discharged, the current efficiency can reach more than 98%, and the energy efficiency is about 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com