Isolated gate field effect transistor and manufacture method thereof

A technology of field effect transistors and manufacturing methods, applied in the field of microelectronics, can solve the problems of threshold voltage drift, dielectric layer thickness cannot be accurately controlled, etc., and achieve the effects of improving structural quality, suppressing current collapse effect, and avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0048] Furthermore, repeated reference numerals or designations may be used in different embodiments. These repetitions are only for the purpose of simply and clearly describing the present invention, and do not represent any relationship between the different embodiments and / or structures discussed.

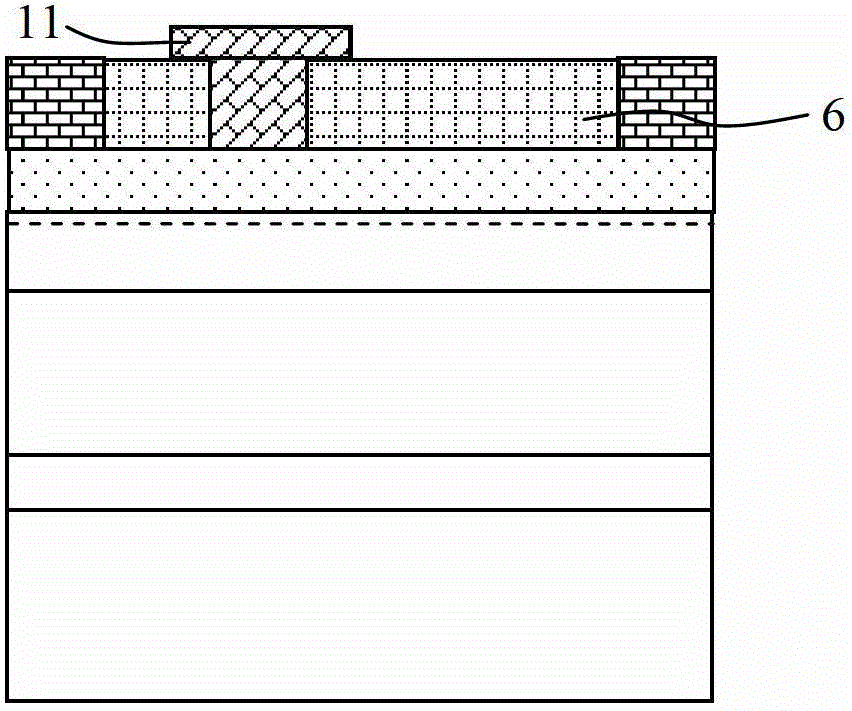

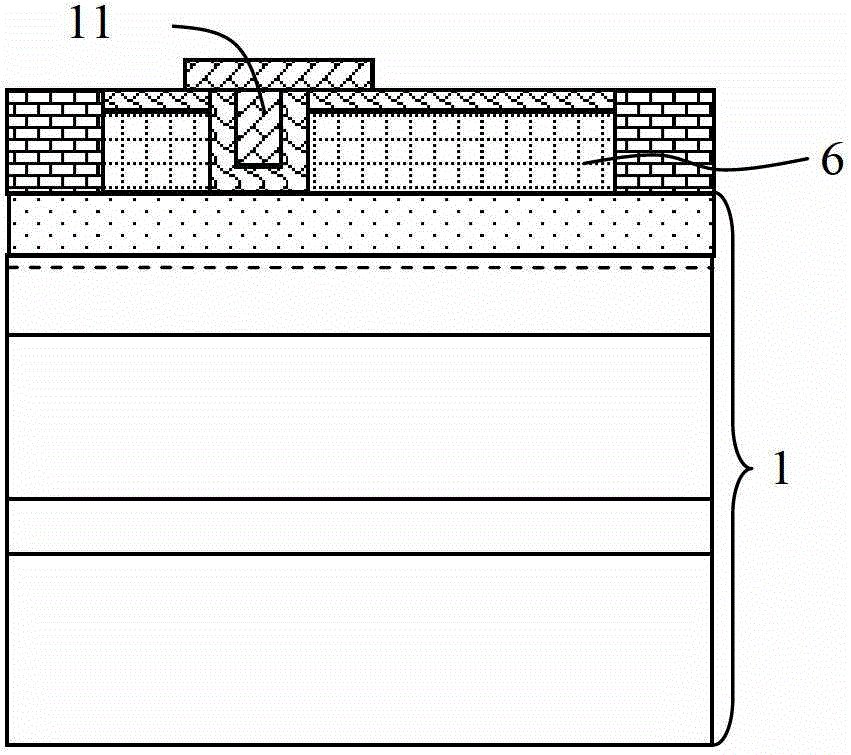

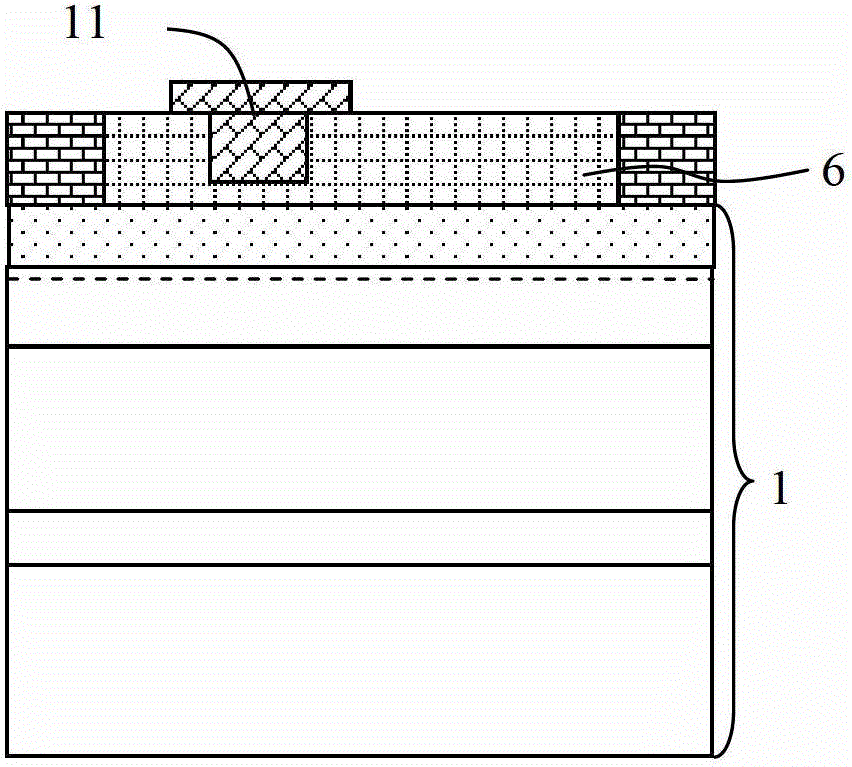

[0049] ginseng Figure 2e As shown, in the first embodiment of the present invention, the insulated gate field effect transistor includes: a substrate 1 and a nitride nucleation layer 2, a nitride buffer layer 3, a nitride channel layer 4, Nitride barrier layer 5, silicon nitride layer 6 (first dielect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com