Bonded NdFeB (neodymium, ferrum and boron) strong magnet and preparation method thereof

A NdFeB and strong magnet technology is applied in the field of bonded NdFeB strong magnets and its preparation. The effect of stability, small dimensional change and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

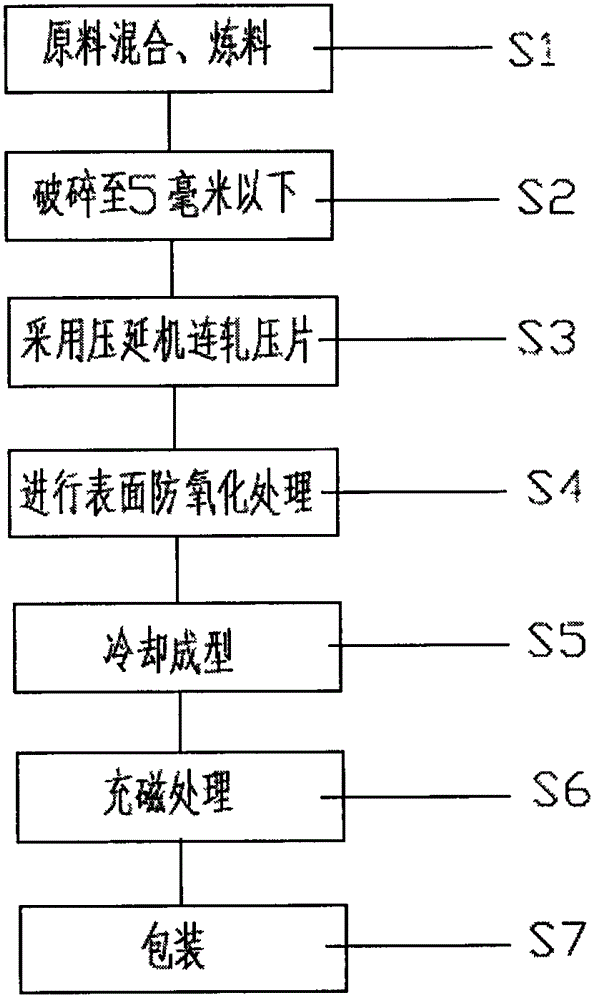

[0027] refer to figure 1 , first put 85% by weight of NdFeB magnetic powder, 2% of ferrite rubber and plastic magnetic powder, 8% of rubber, 0.5% of nylon, and 4.5% of additives into the mixer, and the order of addition should be It depends on the performance requirements of plasticizing rubber, the role of compounding agents, the performance of dispersion and the amount used. In this embodiment, the binder and additives are added first, and then the main material is added to mix materials with different specific gravity evenly. Then put the mixed material into the internal mixer for mixing and plasticization (S1). The mixing temperature should be appropriate. High temperature is conducive to the plastic flow and deformation of raw rubber and rubber material, and is beneficial to the rubber on the surface of solid compound particles. Wetting and mixing to eat powder, but it will reduce the viscosity of the rubber material, which is not conducive to the crushing and dispersion...

Embodiment 2

[0029] refer to figure 1 , first put 87% by weight of NdFeB magnetic powder, 4% of ferrite rubber and plastic magnetic powder, 3.5% of rubber, 0.5% of polyphenylene sulfide, and 5% of additives into the mixer. The sequence should be determined according to the performance requirements of the plasticizing rubber, the role of the compounding agent, the performance of the dispersion and the amount used. In this embodiment, the binder and auxiliary agent are added first, and then the main material is added, so that various materials with different specific gravity are mixed evenly. Then put the mixed material into the internal mixer for mixing and plasticization (S1). The mixing temperature should be appropriate. High temperature is conducive to the plastic flow and deformation of raw rubber and rubber material, and is beneficial to the rubber on the surface of solid compound particles. Wetting and mixing to eat powder, but it will reduce the viscosity of the rubber material, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com