Spunlace non-woven fabric wall paper and production method thereof

A technology of spunlace non-woven fabrics and production methods, applied in textiles and papermaking, paper, papermaking, etc., can solve the problems of poor friction resistance, high requirements for drying equipment, large ink droplets, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

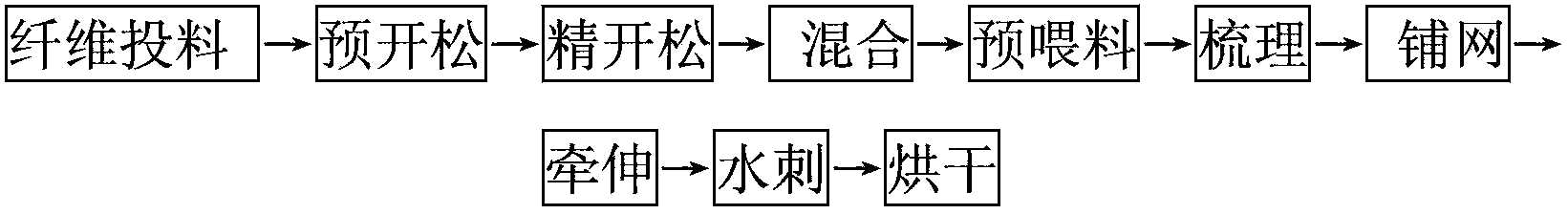

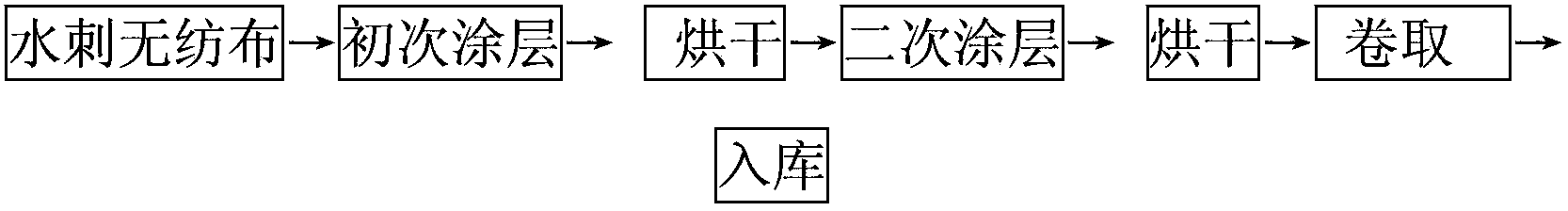

Method used

Image

Examples

Embodiment 1

[0027] The spunlace non-woven fabric wallpaper is composed of spunlace non-woven fabric and coating, in which the weight of spunlace non-woven fabric is 90g / ㎡, and the initial coating material is: acrylic rubber with a solid content of 20%; the dispersant uses Triethylhexyl phosphoric acid, cetylpyridinium chloride in the cationic quaternary ammonium salt as the fixing agent, and 4,4'-bis(4,6-bis) in the phthalimide type as the whitening agent Anilinotriazinyl-2-amino) diphenylethylene-2,2′-sodium disulfonate, nonylphenol polyoxyethylene ether as the defoamer, aluminum oxide flame retardant as the functional additive, and The mass fractions of each material of sizing material, dispersant, color-fixing agent, whitening agent, defoamer and flame retardant are: 90% of sizing material, 5% of dispersing agent, 1% of color-fixing agent, 2% of whitening agent, 1% defoamer, 1% flame retardant. The secondary coating material is: acrylic rubber with a solid content of 20%; the dispersa...

Embodiment 2

[0035] The spunlace non-woven wallpaper is composed of spunlace non-woven fabric and coating, of which the spunlace non-woven fabric is the finished 60g / ㎡ of the existing spunlace non-woven fabric, and the initial coating material is: styrene-acrylic emulsion rubber, containing solid The amount is 30%; the dispersant is polyacrylamide, the color-fixing agent is cetylpyridinium bromide, and the whitening agent is 4,4'-bis(4,6-diphenylaminotriazinyl-2-amine ) Sodium stilbene-2,2′-disulfonate, methyl amyl alcohol as the defoamer, and 500-mesh copper powder as the functional additive. Glue, dispersant, color-fixing agent, brightener and defoamer are added according to the following mass percentages: 90% glue, 5% dispersant, 1% color-fixing agent, 2% brightener, and 1% defoamer , Functional additives 1%. The secondary coating material is: styrene-acrylic emulsion rubber with a solid content of 35%; the dispersant is polyacrylamide, and the defoamer is methyl amyl alcohol. The rubb...

Embodiment 3

[0042] The spunlace non-woven wallpaper is composed of spunlace non-woven fabric and coating, of which the spunlace non-woven fabric is the finished 150g / ㎡ of the existing spunlace non-woven fabric, and the initial coating material is: polyvinyl alcohol resin, solid content 30%; polyacrylamide is used as dispersant, cetylpyridinium chloride is used as color fixing agent, 4-methyl-7-dimethylaminocoumarin is used as whitening agent, methyl amyl alcohol is used as defoamer, The functional auxiliary uses 500 mesh white carbon black powder. Glue, dispersant, color-fixing agent, brightener and defoamer are added according to the following mass percentages: 90% glue, 4.5% dispersant, 0.5% color-fixing agent, 0.5% brightener, and 1.5% defoamer , Functional additives 3%. The secondary coating material is: styrene-acrylic emulsion rubber with a solid content of 35%; the dispersant is polyacrylamide, and the defoamer is methyl amyl alcohol. The rubber, dispersant and defoamer are added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com