Method for comprehensively recovering zinc, lead and silver from waste residues generated in zinc smelting

A zinc smelting and waste residue technology, applied in the field of comprehensive recovery of zinc, lead and silver, can solve problems such as failure to obtain comprehensive recovery, waste of resources, environmental impact, etc., so as to save costs and expenses, improve enterprise economic benefits, environmental protection and social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

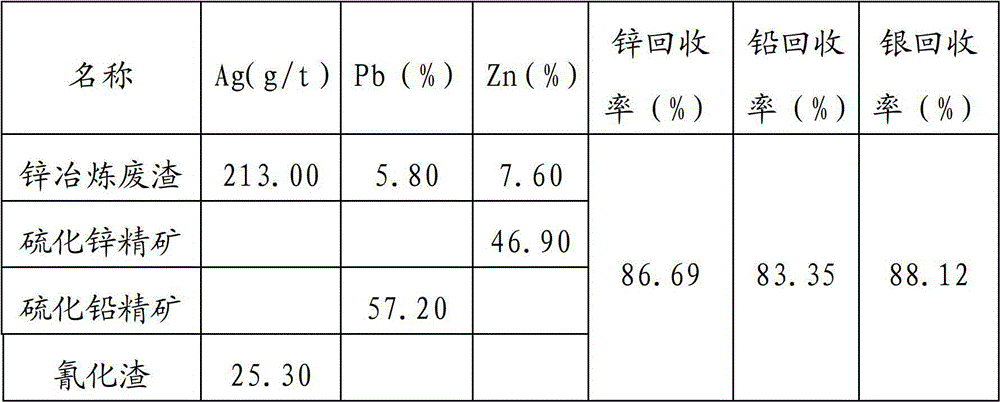

Examples

Embodiment 1

[0023] Zinc smelting waste residue is first mixed with 15% sulfuric acid solution, the liquid-solid mass ratio after mixing is 2:1, the temperature is 80°C, fully reacted for 2 hours, and the acid leaching residue is filtered out; then mixed with 30% sulfuric acid solution The solutions are mixed, the liquid-solid mass ratio after mixing is 2:1, the temperature is 80°C, and the reaction is sufficient for 2 hours to obtain the acid leaching solution containing valuable metals such as zinc and the acid leaching residue containing valuable metals such as lead and silver;

[0024] Add lime to the acid leaching solution, control the pH value = 3.5, purify and remove iron at room temperature, add a sodium sulfide solution with a mass fraction (mass fraction of sodium sulfide solution) of 15% in the solution after iron removal to precipitate zinc, until acid leaching The zinc in the solution is all precipitated, and the zinc concentrate and zinc-precipitated solution containing more t...

Embodiment 2

[0031] Zinc smelting waste slag is first mixed with 15% sulfuric acid solution, the liquid-solid mass ratio after mixing is 3:1, the temperature is 85°C, fully reacted for 3 hours, and the acid leaching residue is filtered out; then mixed with 30% sulfuric acid solution The solution is mixed, the liquid-solid mass ratio after mixing is 3:1, the temperature is 85°C, and the reaction is fully carried out for 3 hours to obtain the acid leaching solution containing valuable metals such as zinc and the acid leaching residue containing valuable metals such as lead and silver;

[0032] Add lime to the acid leaching solution, control the PH value = 3.8, purify and remove iron at room temperature, add a sodium sulfide solution with a mass fraction (mass fraction of sodium sulfide solution) of 15% to precipitate zinc, until the acid leaching The zinc in the solution is all precipitated, and the zinc concentrate and zinc-precipitated solution containing more than 45% zinc are obtained;

...

Embodiment 3

[0039] Zinc smelting waste residue is first mixed with 15% sulfuric acid solution, the liquid-solid mass ratio after mixing is 4:1, the temperature is 90°C, fully reacted for 4 hours, and the acid leaching residue is filtered out; then mixed with 30% sulfuric acid solution The solution is mixed, the liquid-solid mass ratio after mixing is 4:1, the temperature is 90°C, and the reaction is fully carried out for 4 hours to obtain the acid leaching solution containing valuable metals such as zinc and the acid leaching residue containing valuable metals such as lead and silver;

[0040] Add lime to the acid leaching solution, control the PH value = 4.0, purify and remove iron at room temperature, add a sodium sulfide solution with a mass fraction (mass fraction of sodium sulfide solution) of 15% in the solution after iron removal to precipitate zinc, until acid leaching The zinc in the solution is all precipitated, and the zinc concentrate and zinc-precipitated solution containing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com