Converter slag modifier and manufacture and using method thereof

A converter steel slag and modifier technology, applied in the field of steel slag modifier, can solve the problems of serious pollution, no improvement in performance, increased investment in equipment and flue gas treatment facilities, etc., and achieves wide sources, low cost, and stable treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

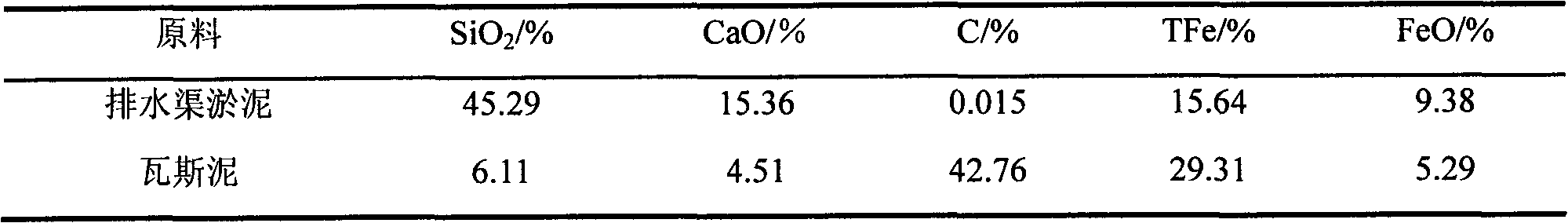

[0031] The raw material of the converter steel slag modifier is the filtered mud cake and blast furnace gas ash after the wastewater treatment of metallurgical enterprises. The composition of the raw material is shown in Table 1 (the balance is impurities).

[0032] Table 1 Raw material composition of converter steel slag stability modifier

[0033]

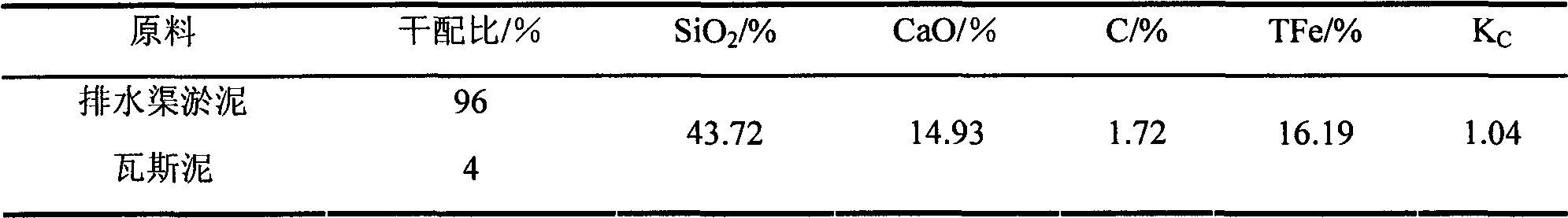

[0034] Table 2 Batching scheme of converter steel slag stability modifier

[0035]

[0036] First dry the wet material in the raw material, the drying temperature is 107°C, then mix the prepared raw material with a mixer, pass the material through a 1mm sieve, the moisture content of the mixed material is 1.6%, and the finished product is used as a converter Slag modifier.

[0037] Before the slag is discharged from the converter, add it into the slag tank along with the slag flow according to 5% of the slag amount. The slag discharge temperature is 1640°C, the cooling rate of the slag tank is about 1°C per minute, and th...

Embodiment 2

[0039] The raw materials of the converter steel slag modifier are the filtered mud cake, blast furnace gas ash and drainage channel sludge after the wastewater treatment of metallurgical enterprises.

[0040] Table 3 Batching scheme of converter steel slag stability modifier

[0041]

[0042] Table 4 Batching scheme of converter steel slag stability modifier

[0043]

[0044]First dry the wet material in the raw material, the drying temperature is 180°C, then mix the prepared raw material with a mixer, pass the material through a 1mm sieve, the moisture content of the mixed material is 1.52%, and the finished product is used as a converter Slag modifier.

[0045] Before the slag is discharged from the converter, 15% of the slag amount is added to the slag tank at one time in advance. The slag discharge temperature is 1610°C, the cooling rate of the slag tank is about 1°C per minute, and the tank temperature is ≥1500°C for about 110 minutes, and then the fully modified ...

Embodiment 3

[0047] The raw materials of the converter steel slag modifier are filtered mud cake after wastewater treatment in metallurgical enterprises, blast furnace gas ash and drainage sludge. The raw material composition is shown in Table 5 (the balance is impurities).

[0048] Table 5 Batching scheme of converter steel slag stability modifier

[0049]

[0050] Table 6 Batching scheme of converter steel slag stability modifier

[0051]

[0052] First dry the wet material in the raw material at a drying temperature of 250°C, then mix the prepared raw material with a mixer, pass the material through a 1mm sieve, and the moisture content of the mixed material is 1.43%, and the finished product is used as a converter Slag modifier.

[0053] Before the slag is discharged from the converter, 25% of the amount of slag is added to the slag tank at one time in advance. The slag discharge temperature is 1600°C, the cooling rate of the slag tank is about 1°C per minute, and the tank temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com