Method for producing baking-free slag bricks by using steel slag sludge of rotating furnace

A converter steel slag and slag brick technology, applied in chemical instruments and methods, mixed operation control devices, sustainable waste treatment, etc., can solve the problems of converter tailings and converter tailings sludge occupying land, polluting the environment, etc., and achieve environmental protection , save energy, solve the effect of occupying land and polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 5% of 32.5 grade Portland slag cement, 40% of converter tailings, and 55% of converter tailings sludge into the mixing equipment, add 5% of water for stirring, and mix for 15 minutes. After mixing, enter The brick press is pressed and formed, and the adobes are sprinkled and maintained for 3 times after stacking. After 15 days, the finished product leaves the factory. The percentages of the above ingredients are percentages by weight.

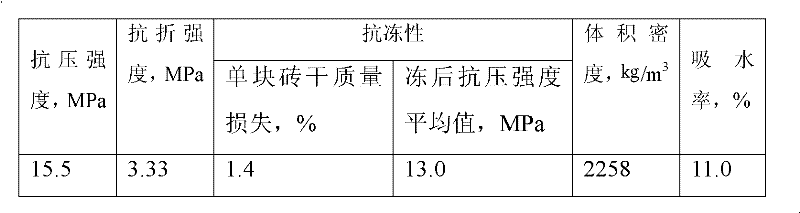

[0021] The factory inspection results are as follows:

[0022]

Embodiment 2

[0024] Add 1000kg of 20% converter tailings and 80% converter tailings mud into the mixing equipment, stir and mix for 15 minutes. After mixing, enter the brick press for pressing and molding. Tianhou finished products leave the factory, and the percentages of the above ingredients are percentages by weight

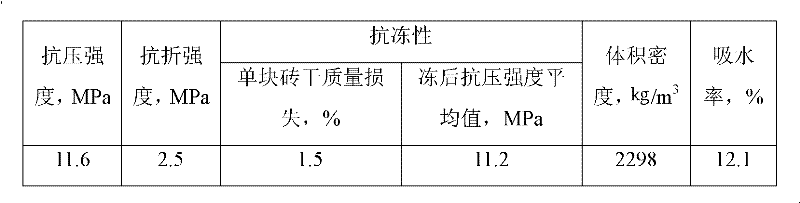

[0025] The factory inspection results are as follows:

[0026]

Embodiment 3

[0028] Add 2% of 32.5 grade Portland slag cement, 48% of converter tailings, and 50% of converter tailings sludge into the mixing equipment, add 4% of water for stirring, and mix for 15 minutes. After mixing, enter The brick press is pressed and formed, and the adobes are sprinkled and maintained for 3 times after stacking. After 15 days, the finished product leaves the factory. The percentages of the above ingredients are percentages by weight.

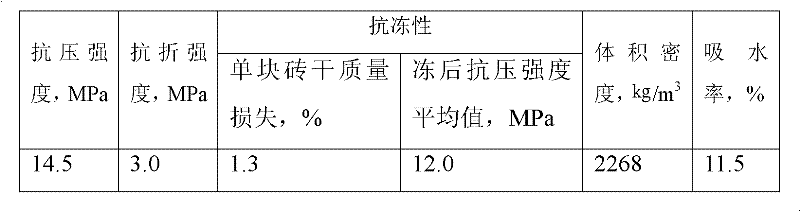

[0029] The factory inspection results are as follows:

[0030]

[0031] In the above-mentioned embodiments: the converter tailings are the remaining wastes after the converter steel slag is hot and stuffy, and passed through the steel slag magnetic separation processing line after crushing, screening and magnetic separation. The particle size is 0-10mm, and the distribution ratio of each component contained is The proportion by weight is: SiO 2 13-17 parts, Al 2 o 3 4-8 parts, Fe 2 o 3 7-21 parts, CaO38-43 parts, MgO9-13 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com