Converter slag stability modifier and application method thereof

A converter steel slag and modifier technology, which is applied in the fields of converter steel slag stability modifier and molten steel slag stability treatment, can solve problems such as unstable performance, interference of blast furnace slag composition, and great impact on subsequent utilization of blast furnace slag. Achieve stable performance, low cost, and achieve the effect of stabilization treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Converter steel slag stability modifier is iron ore magnetic separation tailings slag, the main component is (mass percentage) SiO 2 : 71.95%, Al 2 o 3 : 6.12%, CaO: 4.95%, TFe: 4.50%, MgO: 3.4%, and the balance is impurities. The raw material particle size is less than 1mm.

[0031] Pack it into a 20kg pouch with a woven bag. When smelting Q235A steel grade, add 20% of the total amount of steel slag into the excess flux silo of the converter, and add it at one time after the molten steel is clean. Then, the gun was blown with oxygen for 2 minutes to carry out gas stirring, so that the materials were evenly mixed. Keep warm for 2 minutes. Then discharge the slag into the steel slag tank, the slag discharge temperature is 1610°C, the cooling rate of the slag tank is about 1°C per minute, and the time for the slag tank to keep ≥1500°C is about 110 minutes, so that the CaO in the converter steel slag continues to mix with the SiO in the modifier 2 , FeO and other aci...

Embodiment 2

[0033] Converter steel slag stability modifier is iron ore row rock, the main component is (mass percentage) SiO 2 : 93.46%, Al 2 o 3 : 0.62%, CaO: 0.05%, TFe: 0.50%, MgO: 0.02%, and the balance is impurities. The raw material particle size is less than 1mm.

[0034] Pack it into a 20kg pouch with a woven bag. When smelting Q235A steel, add 18% of the total amount of steel slag into the excess flux silo of the converter, and add it at one time after the molten steel is clean. Then, the gun was blown with oxygen for 1.5 minutes to carry out gas stirring, so that the materials were mixed evenly. Keep warm for 2 minutes. Then discharge the slag into the steel slag tank, the slag discharge temperature is 1600°C, the cooling rate of the slag tank is about 1°C per minute, and the time for the slag tank to maintain ≥1500°C is about 100 minutes, so that the CaO in the converter steel slag continues to mix with the SiO in the modifier 2, FeO and other acidic substances fully reac...

Embodiment 3

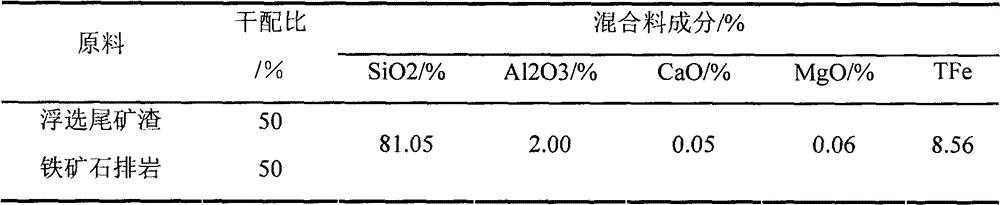

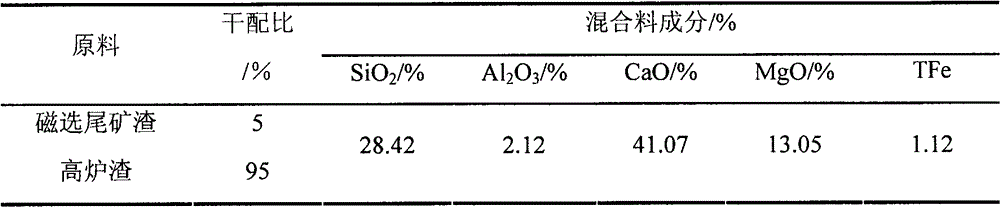

[0036] The batching scheme of converter steel slag stability modifier is shown in Table 1 (the balance is impurities).

[0037] Table 1 Batching scheme of converter steel slag stability modifier

[0038]

[0039] The raw material particle size is less than 1mm. When smelting X60 steel, the modifier is first added to the converter silo at a ratio of 9% of the total amount of steel slag, and then added to the converter at one time after the molten steel is clean. Then, the gun was blown with oxygen for 1 minute to carry out gas stirring, so that the materials were evenly mixed. Then discharge the slag into the steel slag tank, the slag discharge temperature is 1630°C, the cooling rate of the slag tank is about 1°C per minute, and the time for the slag tank to keep ≥1500°C is about 130 minutes, so that the CaO in the converter steel slag continues to mix with the SiO in the modifier 2 , FeO and other acidic substances fully react. Then the fully modified converter steel sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com