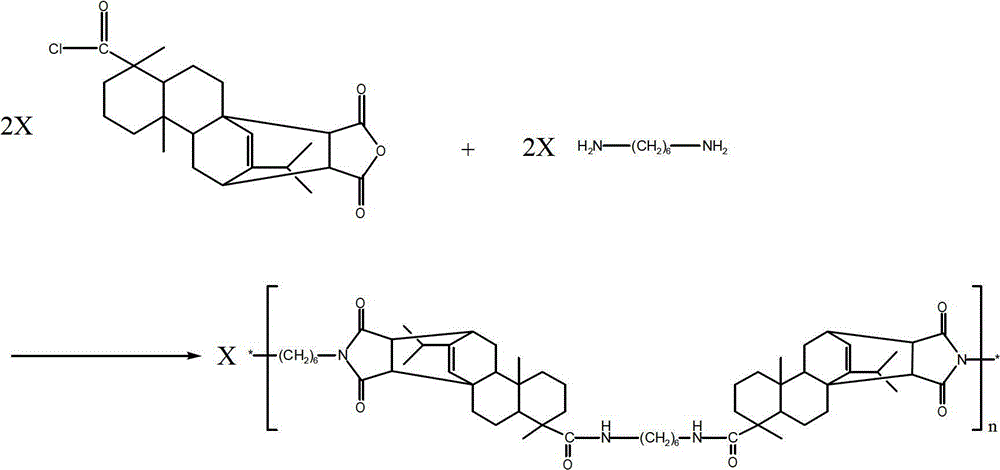

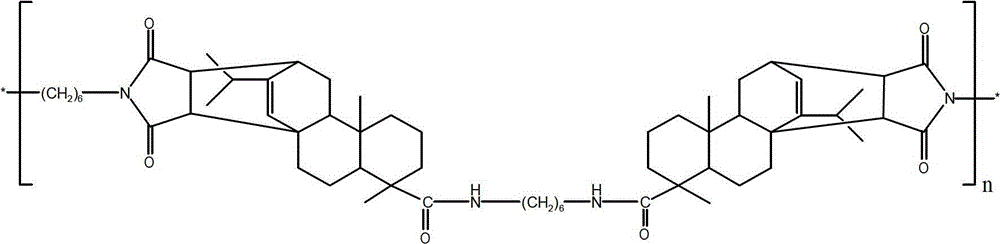

Rosin-based semi-alicyclic polyamide-imide PA6I and synthesizing method thereof

A polyamide-imide and synthesis method technology, applied in the field of rosin-based semi-alicyclic polyamide-imide PA6I and its synthesis, can solve the problems of inconvenient control, large consumption of organic solvent, complicated polymerization process, etc., and achieve convenient The effect of control, convenient operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] ③Preparation of maleopimaric anhydride:

[0034] Add 100 parts by weight of pimaric acid, 17 parts by weight of maleic anhydride, 3.33 parts by weight of p-toluenesulfonic acid (TSA), 55 parts by weight of ice After the acetic acid, pass nitrogen gas for 15 minutes to make the reactants exist in the environment under the protection of nitrogen gas. Slowly heat to 110°C. After the material is basically melted, turn on the stirrer at a stirring speed of 50r / min, and continue to heat up evenly. Adjust the reaction temperature in the bottle by adjusting the amount of acetic acid in the reaction bottle. After the temperature in the reaction bottle rises to After 180° C., keep this temperature for 4 hours, then lower the temperature. When the temperature in the reaction bottle drops to 110° C., add 210 parts by weight of glacial acetic acid and stir evenly. When the material was lowered to room temperature, it was further cooled with ice water, and the white crystalline crud...

Embodiment 1

[0045]Embodiment 1 A kind of synthetic method of rosin-based semialicyclic polyamide-imide PA6I

[0046] Include the following steps:

[0047] (1) Using gum rosin as raw material, prepare maleopimaric acid chloride and dry it in vacuum;

[0048] (2) Add maleopimaric acid chloride and 1,6-hexanediamine in a molar ratio of 1:0.85 (mass ratio: 4.190kg:0.986kg) into the stirred polymerization reactor after vacuum drying, and vacuumize for 1min After passing helium for 30 minutes, this cycle is repeated 20 times, so that the reactant exists in the environment under the protection of helium, and the system pressure in the reactor is controlled to 0.3MPa;

[0049] (3) Seal the polymerization reactor and heat it to 130°C, control the system pressure in the reactor to 1.1MPa, and keep the reactant under pressure for 24 hours, then slowly release the gas to normal pressure;

[0050] (4) Under normal pressure, continue to heat the polymerization reactor to 320°C, keep vacuuming for 1 h...

Embodiment 2

[0051] Embodiment 2 A kind of synthetic method of rosin-based semialicyclic polyamide-imide PA6I

[0052] Include the following steps:

[0053] (1) Using gum rosin as raw material, prepare maleopimaric acid chloride and dry it in vacuum;

[0054] (2) Add maleopimaric acid chloride and 1,6-hexanediamine in a molar ratio of 1:0.95 (mass ratio: 4.190kg:1.102kg) into the stirred polymerization reactor after vacuum drying, and vacuumize for 30 minutes Then pass nitrogen gas for 1 min, and cycle like this once, so that the reactant exists in the environment under the protection of nitrogen gas, and the system pressure in the reactor is controlled to 0.1MPa;

[0055] (3) Seal the polymerization reactor and heat it to 170°C, adjust the stirring speed to 500r / min, control the system pressure in the reactor to 1.3MPa, and keep the reactant under pressure for 0.5h, then slowly release the gas to normal pressure;

[0056] (4) Under normal pressure, continue to heat the polymerization re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com