Mixed ligand cobalt (II) coordination polymer magnetic material, preparation method and application thereof

A technology of coordination polymers and mixed ligands, which is applied in the fields of magnetism of organic materials/organic magnetic materials, cobalt organic compounds, etc., can solve problems such as limited research, and achieve good reproducibility, high yield, and high thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Synthesis of 5-methyl-1H-tetrazolium and 2,3-pyrazinedicarboxylic acid mixed ligand cobalt(II) complex A:

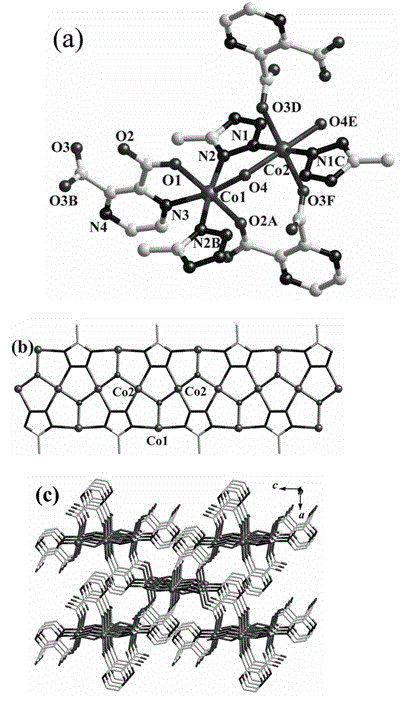

[0028] Dissolve 5-methyl-1H-tetrazole (0.2 mmol, 16.8 mg), 2,3-pyrazinedicarboxylic acid (0.1 mmol, 16.8 mg) and cobalt acetate tetrahydrate (0.2 mmol, 49.8 mg) In double-distilled water (10.0 mL), adjust the pH to 4 with triethylamine, stir for several minutes, and seal it into a hydrothermal kettle. at 180 o After incubation at C for 4 days, the temperature was programmed to cool down to room temperature to obtain a red bulky single crystal, which was then washed with twice distilled water and dried in air. See figure 1 crystal structure diagram.

Embodiment 2

[0030] Synthesis of 5-methyl-1H-tetrazolium and 2,3-pyrazinedicarboxylic acid mixed ligand cobalt(II) complex B:

[0031] Dissolve 5-methyl-1H-tetrazole (0.2 mmol, 16.8 mg), 2,3-pyrazinedicarboxylic acid (0.1 mmol, 16.8 mg) and cobalt acetate tetrahydrate (0.2 mmol, 49.8 mg) In double-distilled water (10.0 mL), adjust the pH to 5 with triethylamine, stir for several minutes, and seal it into a hydrothermal kettle. at 180 o After incubation at C for 4 days, the temperature was programmed to cool down to room temperature to obtain a red bulky single crystal, which was then washed with twice distilled water and dried in air. See figure 1 crystal structure diagram.

Embodiment 3

[0033] Synthesis of 5-methyl-1H-tetrazolium and 2,3-pyrazinedicarboxylic acid mixed ligand cobalt(II) complex C:

[0034] Dissolve 5-methyl-1H-tetrazole (0.2 mmol, 16.8 mg), 2,3-pyrazinedicarboxylic acid (0.1 mmol, 16.8 mg) and cobalt acetate tetrahydrate (0.2 mmol, 49.8 mg) In double-distilled water (15.0 mL), adjust the pH to 4 with triethylamine, stir for several minutes, and seal it into a hydrothermal kettle. at 170 o After incubation at C for 4 days, the temperature was programmed to cool down to room temperature to obtain a red bulky single crystal, which was then washed with twice distilled water and dried in air. See figure 1 crystal structure diagram.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com