High methoxyl pectin (HM) series oily sewage purification agent and preparation method thereof

A technology of oily sewage and purification agent, which is applied in separation method, flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problem of multi-stage sedimentation with large dosage, unsatisfactory effect and difficult recovery of crude oil and other problems, to achieve the effects of obvious oil separation effect, good economic and social benefits, and saving pharmaceutical costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

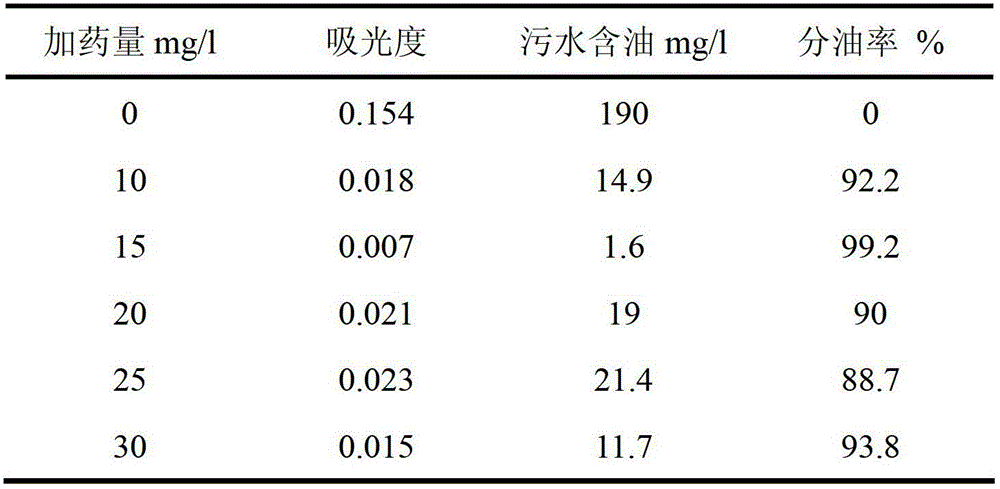

Embodiment 1

[0045] The HM series oily sewage cleaning agent of the present invention comprises the following mass percentages: 35% polyamine, 15% nonionic polyether phosphate and 50% methanol,

[0046] Among them, the nonionic polyether phosphate is ethylene oxide / propylene oxide random copolyether with fatty alcohol as the initiator, which is obtained by esterification reaction with phosphorus pentoxide; polyamine is synthesized by fatty amine and catalyst Afterwards, react with epichlorohydrin to obtain.

[0047] A synergist is also added, and the synergist accounts for 40% of the total mass of polyamine, nonionic polyether phosphate and methanol.

[0048] The synergist, by mass, consists of 35 parts of polyaluminum chloride and 25 parts of polyferric sulfate.

[0049] The preparation method comprises the following steps:

[0050] 1) Add fatty alcohol starter and catalyst into the reaction kettle, sweep the kettle with nitrogen, raise the temperature to 90°C, and after vacuum treatmen...

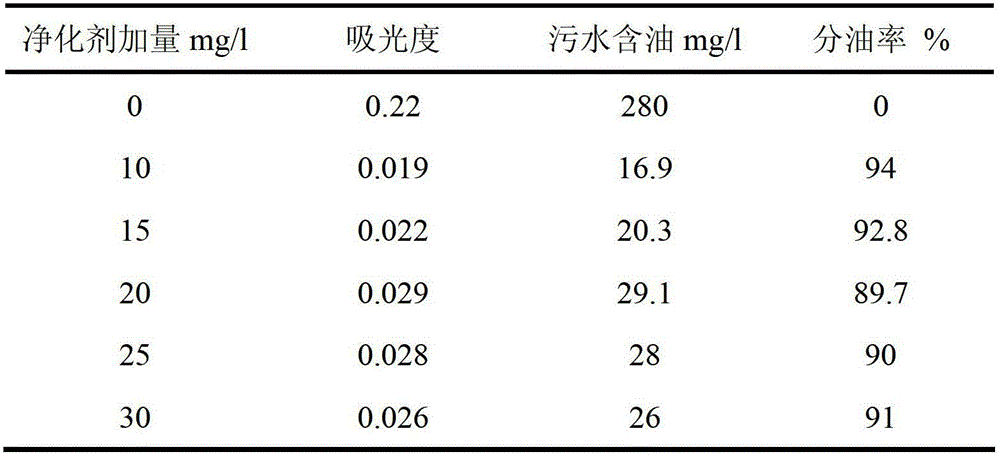

Embodiment 2

[0055] The HM series oily sewage cleaning agent of the present invention comprises the following mass percentages: 12% polyamine, 25% nonionic polyether phosphate and 57% ethanol,

[0056] Among them, the nonionic polyether phosphate is ethylene oxide / propylene oxide random copolyether with fatty alcohol as the initiator, which is obtained by esterification reaction with phosphorus pentoxide; polyamine is synthesized by fatty amine and catalyst Afterwards, react with epichlorohydrin to obtain.

[0057] A synergist is also added, and the synergist accounts for 35% of the total mass of polyamine, nonionic polyether phosphate and ethanol.

[0058] The synergist, by mass, consists of 25 parts of polyaluminum chloride and 45 parts of polyferric sulfate.

[0059] The preparation method comprises the following steps:

[0060] 1) Add fatty alcohol starter and catalyst into the reaction kettle, sweep the kettle with nitrogen, raise the temperature to 95°C, and after vacuum treatment ...

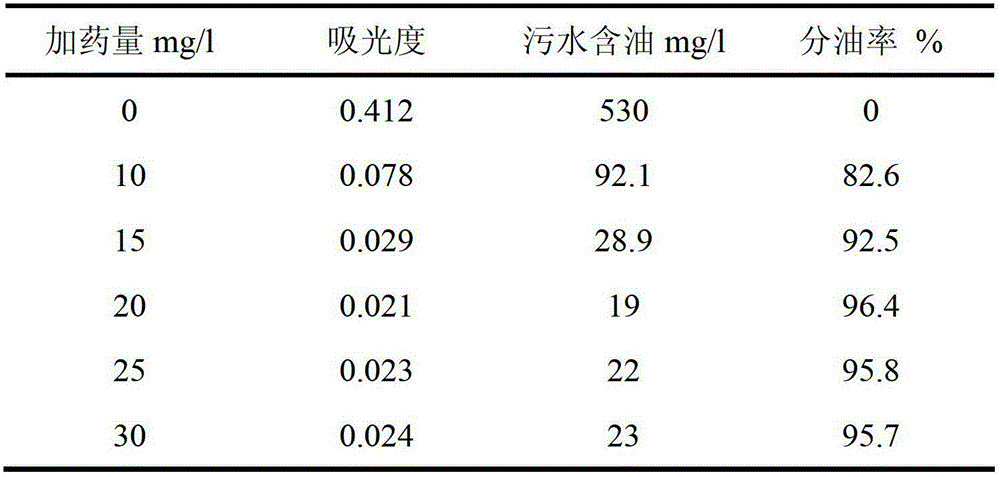

Embodiment 3

[0065] The HM series oily sewage cleaning agent of the present invention comprises the following mass percentages: 20% polyamine, 17% nonionic polyether phosphate and 64% isopropanol,

[0066] Among them, the nonionic polyether phosphate is ethylene oxide / propylene oxide random copolyether with fatty alcohol as the initiator, which is obtained by esterification reaction with phosphorus pentoxide; polyamine is synthesized by fatty amine and catalyst Afterwards, react with epichlorohydrin to obtain.

[0067] A synergist is also added, and the synergist accounts for 25% of the total mass of polyamine, nonionic polyether phosphate and isopropanol.

[0068] The synergist, by mass, consists of 70 parts of polyaluminum chloride and 30 parts of polyferric sulfate.

[0069] The preparation method comprises the following steps:

[0070] 1) Add aliphatic alcohol initiator and catalyst into the reaction kettle, sweep the kettle with nitrogen, raise the temperature to 90°C, and after vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com