High temperature resistant wire rope core flame-retardant conveying belt

A steel cord core and high-temperature-resistant technology, which is applied in conveyors, transportation and packaging, etc., can solve problems such as unsatisfactory safe and economical transportation of high-temperature materials, and achieve good flame retardancy, no decrease in adhesive strength, and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

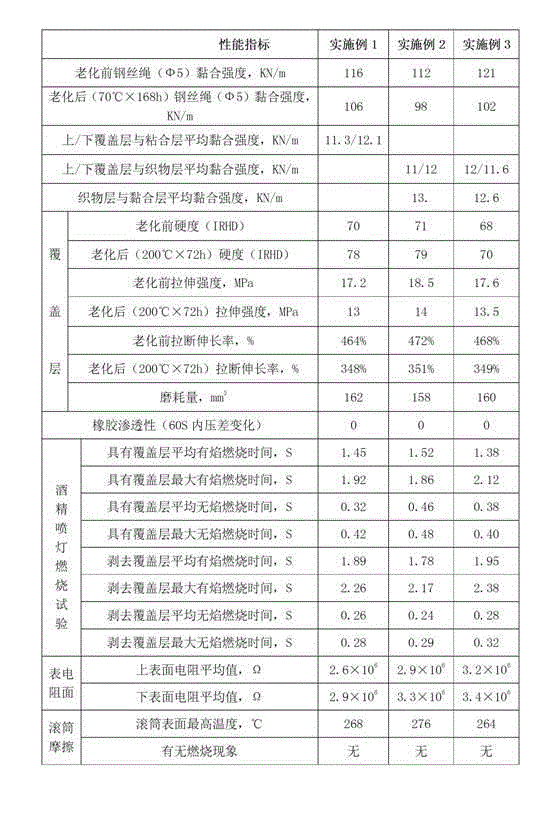

Embodiment 1

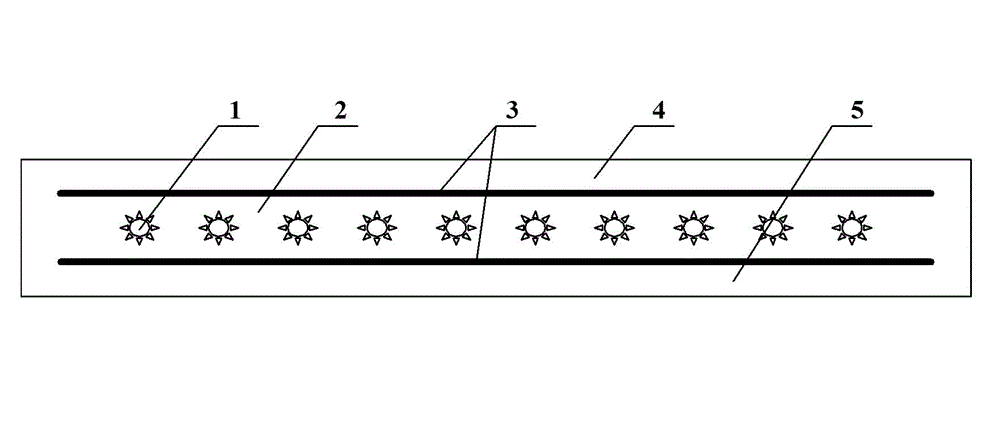

[0013] The high temperature resistant steel cord flame retardant conveyor belt of the present invention comprises a steel cord core 1, an intermediate rubber layer 2, an upper covering rubber layer 4 and a lower covering rubber layer 5, wherein: the upper covering rubber layer 4, the lower covering The rubber layer 5 is high temperature resistant flame retardant vulcanized rubber. The formula of the rubber material is: 50 parts of EPDM rubber, 25 parts of chlorinated butyl rubber, 25 parts of chlorinated polyethylene rubber, 6 parts of dicumyl peroxide 1 part of sulfur, 0.5 part of tert-octylphenol formaldehyde resin, 1 part of epoxy resin, 8 parts of zinc oxide, 2 parts of stearic acid, 1 part of accelerator dibenzothiazole disulfide, accelerator diethyl dithioamino 1 part of zinc formate, 1 part of accelerator tetramethylthiuram disulfide, 1 part of antiaging agent 2,2,4-trimethyl-1,2-dihydroquinoline, antiaging agent N-phenyl-β- 1 part of naphthylamine, 10 parts of conducti...

Embodiment 2

[0016] The high-temperature-resistant steel cord flame-retardant conveyor belt of the present invention comprises a steel cord core 1, an intermediate rubber layer 2, an upper covering rubber layer 4, and a lower covering rubber layer 5, wherein:

[0017] The upper cover rubber layer 4 and the lower cover rubber layer 5 are high-temperature-resistant flame-retardant vulcanized rubber, and the formula of the rubber material is: 40 parts of EPDM rubber, 30 parts of chlorinated butyl rubber, chlorosulfonated poly 30 parts of vinyl rubber, 5 parts of dicumyl peroxide, 1 part of sulfur, 1 part of tert-octylphenol formaldehyde resin, 1 part of epoxy resin, 8 parts of zinc oxide, 2 parts of stearic acid, accelerator diethyl disulfide 1 part zinc carbamate, 1 part zinc dibutyl dithiocarbamate accelerator, 1 part 2-mercaptobenzothiazole accelerator, 1 part zinc dibutyl dithiocarbamate anti-aging agent, 2 anti-aging agents - 1 part of mercaptan benzothiazole, 15 parts of conductive car...

Embodiment 3

[0021] The high temperature resistant steel cord flame retardant conveyor belt of the present invention comprises a steel cord 1, an intermediate rubber layer 2, an upper covering rubber layer 4, and a lower covering rubber layer 5, wherein:

[0022] The upper covering rubber layer 4 and the lower covering rubber layer 5 are high temperature resistant vulcanized rubbers, and the formula of the rubber material is by weight: 30 parts of EPDM rubber, 35 parts of chlorinated butyl rubber, 35 parts of neoprene rubber, 4 parts of dicumyl peroxide, 0.5 parts of sulfur, 0.5 parts of tert-octylphenol formaldehyde resin, 1 part of epoxy resin, 5 parts of zinc oxide, 4 parts of magnesium oxide, 2 parts of stearic acid, accelerator 2-thiol 1 part of benzothiazole, 1 part of dibenzothiazole disulfide, 2,2 parts of antioxidant , ,-methylenebis(4-methyl-6-tert-butylphenol) 1 part, anti-aging agent N-isopropyl-N , - 1 part of phenyl-p-aniline, 10 parts of conductive carbon black, 35 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com