Foaming agent for flotation

A technology of foaming agent and function, applied in flotation, solid separation, organic chemistry, etc., can solve the problem of large amount of foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

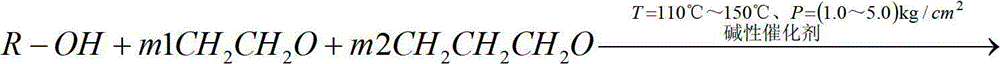

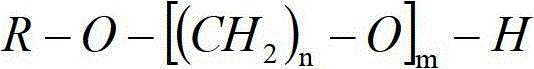

Method used

Image

Examples

Embodiment 1

[0024] According to the molar ratio of 1:2.0, pentanol was weighed for use. First, pentanol was put into the reaction kettle and heated, then a basic catalyst was added and heated, and then a quantitative amount of propylene oxide was added to carry out the addition reaction. ℃~130℃, the pressure is (1.0~3.0) kg / cm 2 , after the reaction is finished, the mixed solution is aged and cooled, and compound A is finally isolated.

Embodiment 2

[0026] According to the molar ratio of 1:2.0, weigh the hexanol for use, first put the hexanol into the reactor and heat it, then add the basic catalyst and heat it, and then add a certain amount of ethylene oxide to carry out the addition reaction, and control the reaction temperature 110℃~130℃, the pressure is (1.0~3.0) kg / cm 2 , after the reaction is finished, the mixed solution is aged and cooled, and compound A is finally isolated.

Embodiment 3

[0028] According to the molar ratio of 1:2.5, weigh the heptanol for use, first put the heptanol into the reaction kettle and heat it, then add the basic catalyst and heat it, and then pass a quantitative amount of ethylene oxide or propylene oxide to carry out the addition reaction , control the reaction temperature at 110°C-140°C, and the pressure at (1.0-4.0) kg / cm 2 , after the reaction is finished, the mixed solution is aged and cooled, and compound A is finally isolated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com