Catalyst for synthesis of hydrocarbons from CO and H2 and preparation method thereof

一种催化剂、合成烃的技术,应用在烃的催化剂,及其制备领域,能够解决制备方法难以实施、组分含量高、高成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

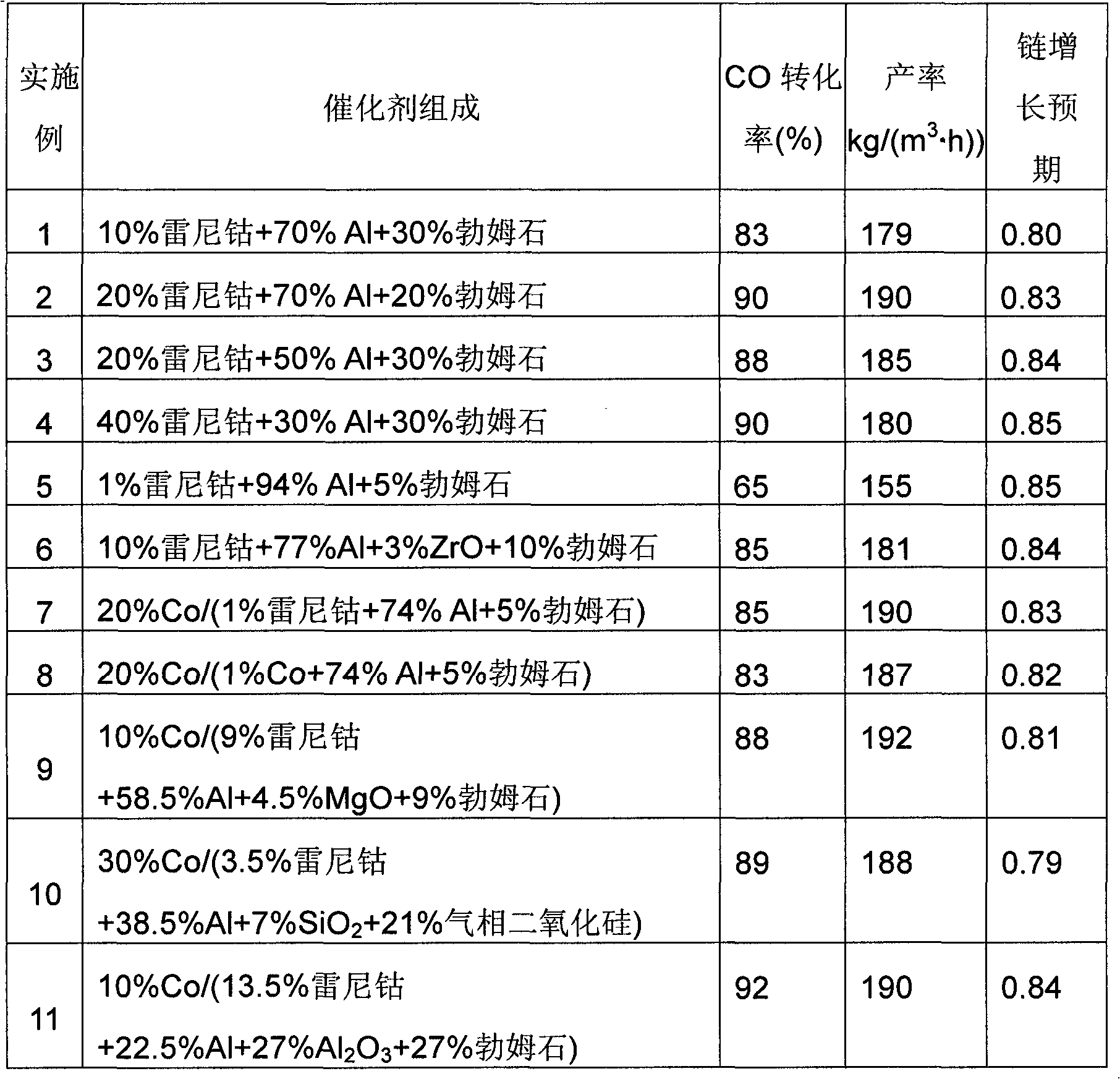

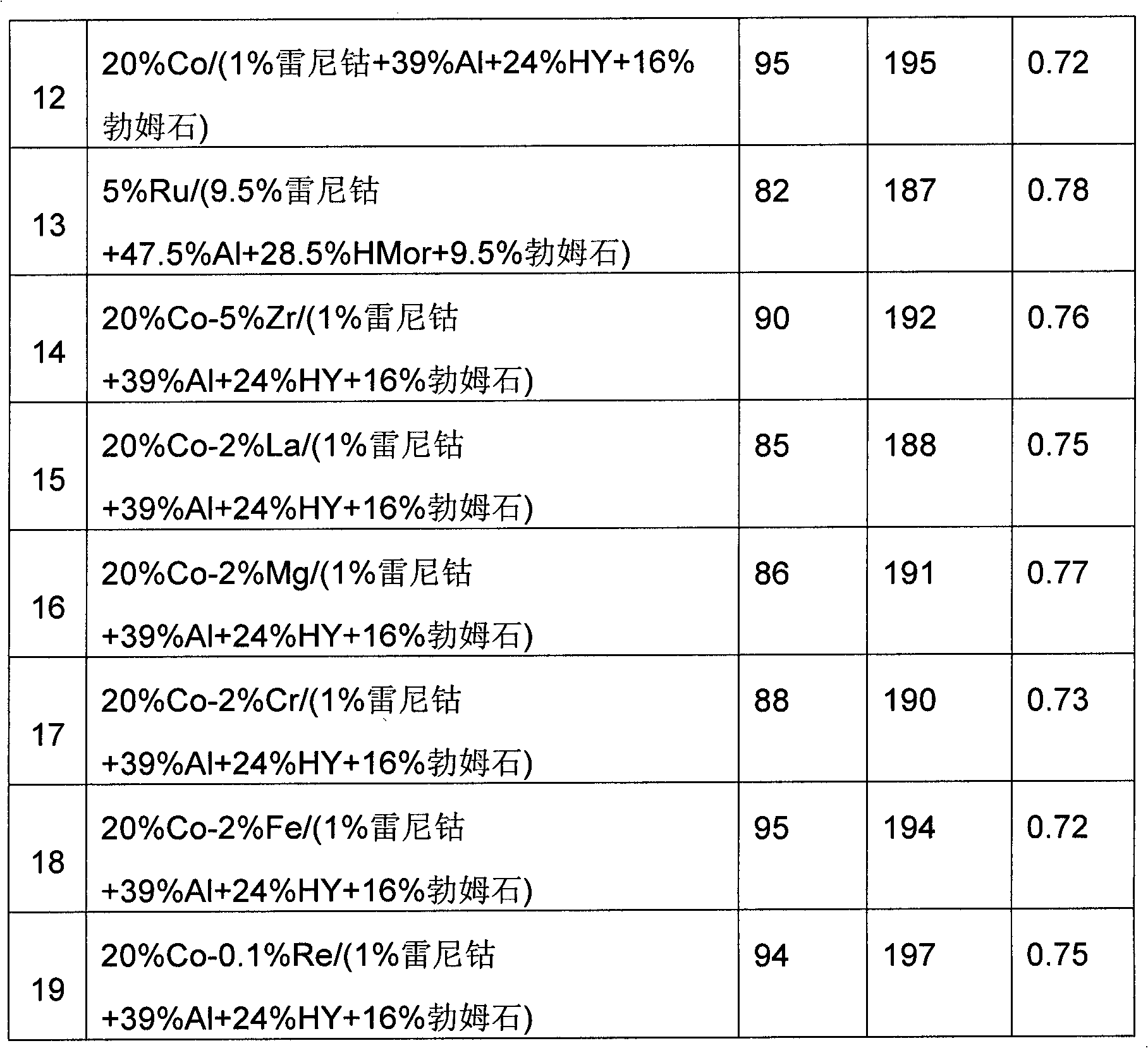

Examples

preparation example Construction

[0038] The inventors successfully prepared for the first time a catalyst for CO and H 2 Synthetic hydrocarbons, especially C 5 ~C 100 Catalysts of hydrocarbons having the above-mentioned advantages and none of the disadvantages mentioned.

[0039] In the catalyst, due to the compounding of Raney cobalt and metal aluminum as active components, it becomes a reality.

[0040] The inventor's research shows that only when the uniform paste containing Raney cobalt disperse particles, metal aluminum and binder is extruded, a three-dimensional thermally conductive frame with metal aluminum embedded in Raney cobalt disperse particles can be prepared. particles. This structure of the catalyst provides a high thermal conductivity and on the other hand enables the use of less active metals. Therefore, Raney cobalt has two roles: active component of the catalyst and component of the three-dimensional thermally conductive framework.

[0041] It is important that the active metals are not...

Embodiment 1

[0071] The catalyst sample contains 10% Raney cobalt+70% aluminum (Al)+20% boehmite, the preparation method is as follows:

[0072] 0.5g boehmite, 1.75g PAP-2 grade aluminum powder and 0.25g Raney cobalt powder were added to the 3 (64%), 2.5 ml distilled water and 0.15 ml triethylene glycol (TEG) in the liquid phase, stirring continuously until a homogeneous mixture is obtained. The mixture was then extruded using a die with a diameter of 2.5 mm. The granules are dried in a drying oven. The physical condition of drying is 25-120°C for 20 hours. The dried particles were then calcined in a calciner under the following conditions: under air atmosphere, the temperature was raised from 120°C to 190°C at a heating rate of 35°C / h, from 190°C to 250°C at a heating rate of 15°C / h, h Heating rate The temperature is raised to 250-450°C, and the particles are calcined at 450°C for 5 hours. The pellets were then cooled to room temperature and cut into 2.5 mm slices.

Embodiment 2

[0074] The catalyst sample contains 20% Raney cobalt+70% aluminum (Al)+10% boehmite, the preparation method is as follows:

[0075] 0.25g boehmite, 1.75g PAP-2 grade aluminum powder and 0.5g Raney cobalt powder were added to the 3 (64%), 2ml distilled water and 0.15ml triethylene glycol (TEG) in the liquid phase. Stirring is continued until a homogeneous mixture is obtained. The mixture was then extruded using a die with a diameter of 2.5 mm. The obtained granules were dried, calcined, cooled and chipped as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com