Preparation method of silicon-silver composite anode material of lithium ion battery and reaction kettle

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low electrical conductivity, complicated manufacturing process, and powdered electrical conductivity of silicon negative electrode materials, so as to suppress volume expansion and improve reversibility. capacity, the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a silicon-silver composite negative electrode material for a lithium-ion battery, the specific steps of which are as follows:

[0034] (1) Pretreatment: Take 1 g of silicon powder particles with a particle size of 80 nm, add them to the acetone solution, wash for 20 minutes, and filter with suction, then add 50 ml of 0.1 mol / L NaOH solution, stir for 1 hour, and pump Filter and wash until the solution is neutral;

[0035] (2) Weigh 1 g AgNO 3 , dissolved in ammonia water with a concentration of 1 mol / L, and magnetically stirred until the solution was clear;

[0036] (3) Take 6 g of glucose solution, add 0.6 g of tartaric acid, 12.5 ml of absolute ethanol, add water and mix to prepare 125 ml of reducing solution;

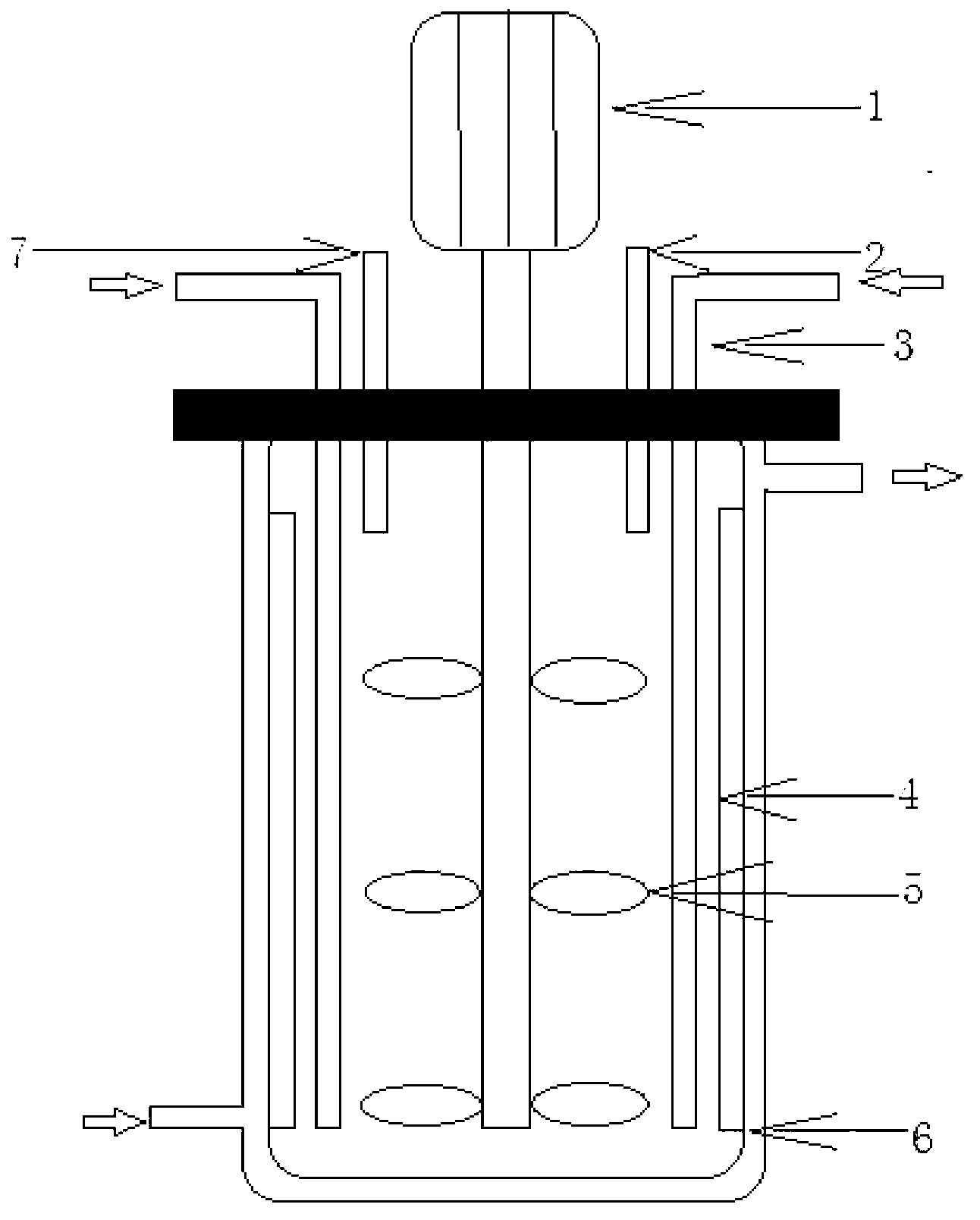

[0037] (4) Prepare 1 L of mother liquor with a concentration of 1 mol / L in distilled water and ammonia water, control the temperature of the reactor at 10 °C, add silicon powder particles into the mother liquor, adjust the mechanical s...

Embodiment 2

[0045] A method for preparing a silicon-silver composite negative electrode material for a lithium-ion battery, the specific steps of which are as follows:

[0046] (1) Pretreatment: Take 1 g of silicon powder particles with a particle size of 300 nm, add them to the acetone solution, wash for 40 minutes, and filter with suction, then add 100 ml of 0.2 mol / L HF solution, stir for 1 hour, and pump Filter and wash until the solution is neutral;

[0047] (2) Weigh 1 g AgNO 3 , dissolved in ammonia water with a concentration of 2 mol / L, stirred with a magnetic force until the solution is clear;

[0048] (3) Take 10 g of glucose solution, add 1 g of tartaric acid, 20 ml of absolute ethanol, add water and mix to prepare 200 ml of reducing solution;

[0049] (4) Prepare 1 L2 mol / L mother liquor with distilled water and ammonia water, control the temperature of the reactor at 15 °C, add silicon powder particles into the mother liquor, and adjust the mechanical stirring speed to 1800 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com