Method for producing ethanol by adopting mixed culture organism by means of glycerol fermentation

A technology of mixed culture and microorganisms, applied in the field of fermentation, can solve problems such as unfavorable growth of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

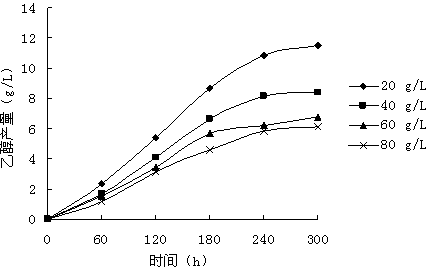

[0024] This implementation case illustrates the impact of different initial concentrations of glycerol on ethanol production. Fill 400 mL of medium in a 1 L Erlenmeyer flask, the medium is peptone 2, yeast powder 2, magnesium sulfate 1.5, dipotassium hydrogen phosphate 5, dihydrogen phosphate Potassium 5, ammonium sulfate 1, pH 4.5, and glycerin concentrations were 20 g / L, 40 g / L, 60 g / L, and 80 g / L, respectively. Put the prepared red yeast seed liquid into the fermentation medium with an inoculation amount of 5%, and culture it with shaking at 32°C and 180 rpm / min for 48 h; inoculate the prepared Bacillus macerans into the red yeast rice according to the inoculum amount of 10% In the fermentation broth, the culture was static at 41°C; 100 mL of fresh red yeast rice broth containing 20 g / L glycerol was added every 60 h, and fermented for 300 h. After the fermentation, the ethanol concentration in the fermentation broth was detected by gas chromatography. get results like fig...

Embodiment 2

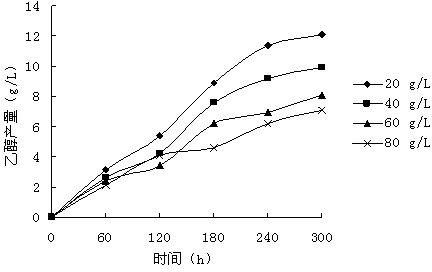

[0027] This implementation case illustrates the influence of different glycerol concentrations in feed on ethanol production. Fill 400 mL of medium in a 1 L Erlenmeyer flask, the medium is glycerol 20, peptone 2, yeast powder 2, magnesium sulfate 1.5, dipotassium hydrogen phosphate 5. Potassium dihydrogen phosphate 5, ammonium sulfate 1, pH 4.5. Put the prepared red yeast seed liquid into the fermentation medium with an inoculation amount of 5%, and culture it with shaking at 32°C and 180 rpm / min for 48 h; inoculate the prepared Bacillus macerans into the red yeast rice according to the inoculum amount of 10% The fermentation broth was cultured at 41°C; 100 mL of fresh red yeast broth containing 20 g / L, 40 g / L, 60 g / L, and 80 g / L glycerol was added every 60 h, and fermented for 300 h. After the fermentation, the ethanol concentration in the fermentation broth was detected by gas chromatography. get results like figure 2 shown.

[0028] Have figure 2 It can be seen that d...

Embodiment 3

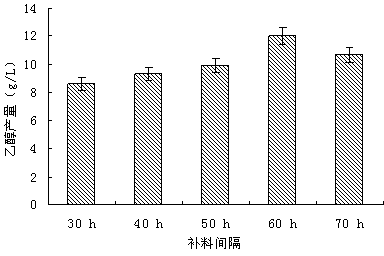

[0030] This implementation case illustrates the influence of different feeding time intervals on ethanol production in feeding. Put 400 mL of medium in a 1 L Erlenmeyer flask. The medium is glycerol 20, peptone 2, yeast powder 2, magnesium sulfate 1.5, hydrogen phosphate Dipotassium 5, potassium dihydrogen phosphate 5, ammonium sulfate 1, pH 4.5. Put the prepared red yeast seed liquid into the fermentation medium with an inoculation amount of 5%, and culture it with shaking at 32°C and 180 rpm / min for 48 h; inoculate the prepared Bacillus macerans into the red yeast rice according to the inoculum amount of 10% In the fermentation broth, culture at 41°C; add 100 mL fresh red yeast rice broth containing 20 g / L glycerol at regular intervals, the time intervals are 30 h, 40 h, 50 h, 60 h, 70 h, and ferment 300 h. After the fermentation, the ethanol concentration in the fermentation broth was detected by gas chromatography. get results like image 3 shown.

[0031] Depend on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com