Fog seal modified emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and fog seal layer, which can be applied to cohesive pavement paved on site, building components, building insulation materials, etc. Good consolidation performance, short closed traffic time, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

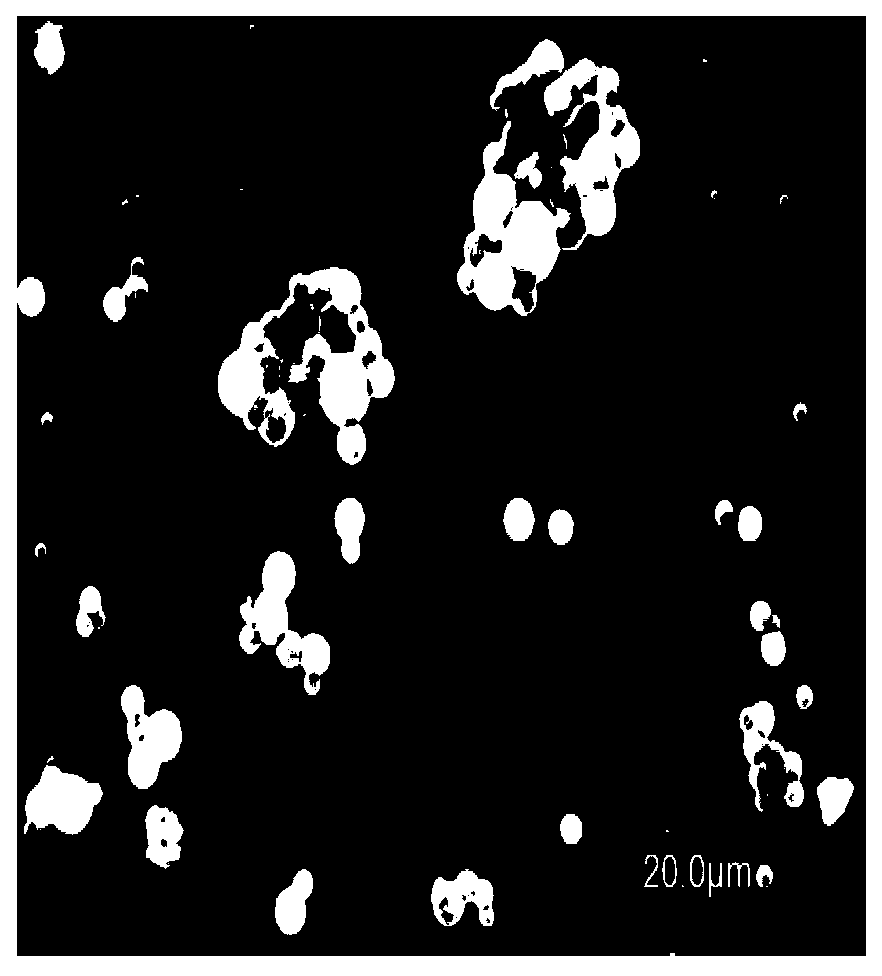

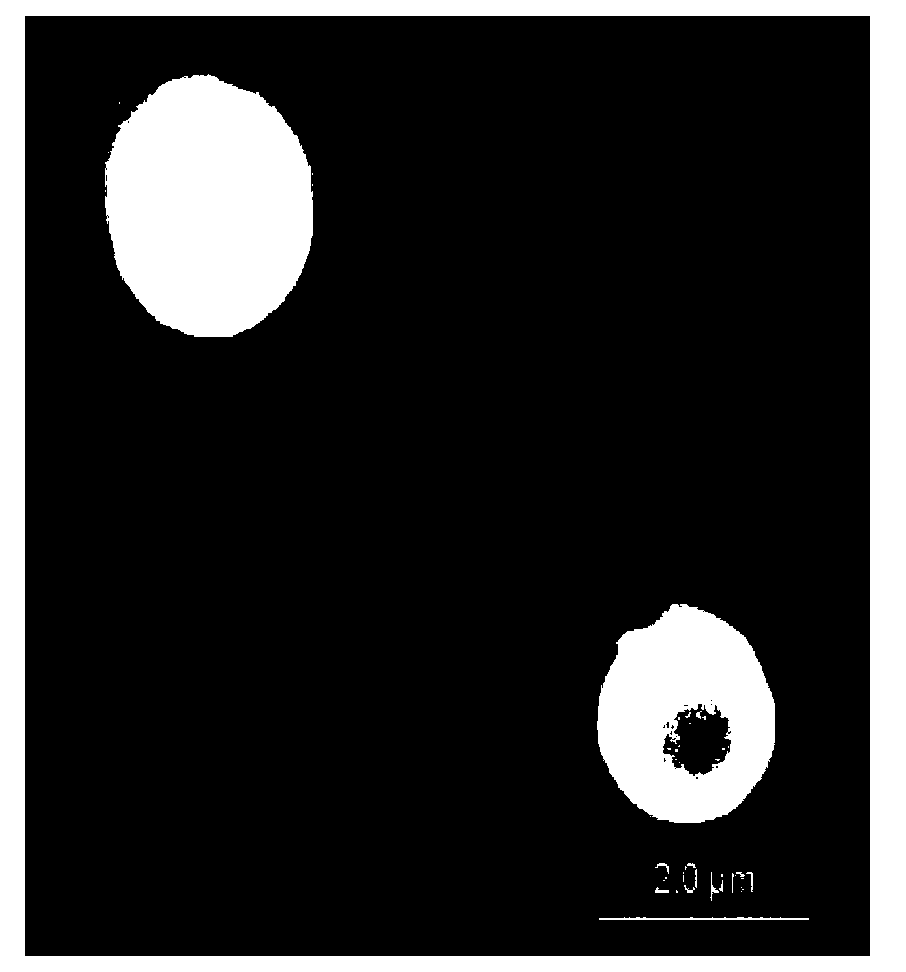

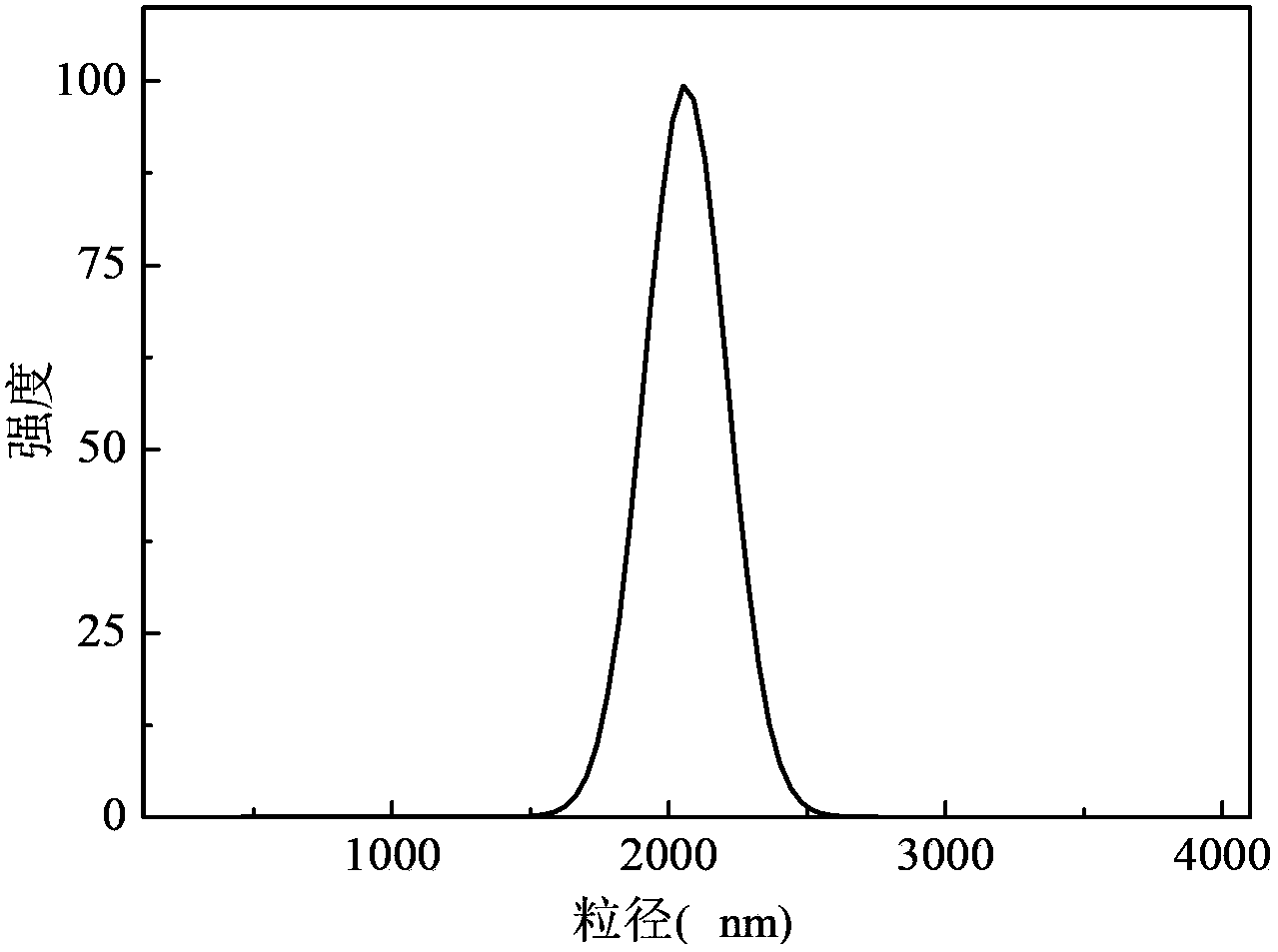

Image

Examples

Embodiment 1

[0031] Taking the preparation of 1 kg of modified emulsified asphalt as an example, the mass ratio of raw materials used is as follows:

[0032]

[0033]

[0034] C in this example 5 Petroleum resin and natural asphalt constitute asphalt modifier, tall oil pitch and furfural extracted oil constitute asphalt rejuvenator, asphalt emulsifier BE-3 and alkylphenol polyoxyethylene ether OP-10 constitute compound emulsifier.

[0035] Its preparation method is as follows:

[0036] 1. Preparation of modified asphalt

[0037] Add 90# base asphalt into the beaker, heat to 130°C, add C 5 Petroleum resin, natural asphalt, tall oil asphalt, and furfural extract oil, stir and mix evenly to obtain modified asphalt, keep warm at 125-160°C for standby.

[0038] 2. Prepare the aqueous solution of compound emulsifier

[0039] Weigh asphalt emulsifier BE-3 and alkylphenol polyoxyethylene ether OP-10, add water and stir until completely dissolved to prepare a compound emulsifier aqueous s...

Embodiment 2

[0043] Taking the preparation of 1 kg of modified emulsified asphalt as an example, the mass ratio of raw materials used is as follows:

[0044]

[0045] C in this example 5Petroleum resin and natural asphalt constitute asphalt modifier, tall oil pitch and furfural extract oil constitute asphalt rejuvenator, asphalt emulsifier BE-3 and alkylphenol polyoxyethylene ether OP--10 constitute compound emulsifier.

[0046] The preparation method is the same as in Example 1, and the modified emulsified asphalt is prepared into a mist seal layer.

Embodiment 3

[0048] Taking the preparation of 1 kg of modified emulsified asphalt as an example, the mass ratio of raw materials used is as follows:

[0049]

[0050] C in this example 5 Petroleum resin and natural asphalt constitute asphalt modifier, tall oil pitch and furfural extracted oil constitute asphalt rejuvenator, asphalt emulsifier BE-3 and alkylphenol polyoxyethylene ether OP-10 constitute compound emulsifier.

[0051] The preparation method is the same as in Example 1, and the modified emulsified asphalt is prepared into a mist seal layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com