Composition for processing polystyrene porous material, polystyrene porous material and preparation method thereof

A technology of polystyrene and porous materials, applied in the field of polymers, can solve the problems of high cost, high price of carbon fiber, large amount of addition, etc., and achieve the effect of easy technology mastering, simple and feasible processing, and reduced density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] By weight percentage, take polystyrene (HIPS-641, Shanghai Secco Petrochemical Co., Ltd.) 72%, lubricant (Rome 2 type calcium stearate, Shanghai Aoke Chemical Co., Ltd.) 2% and anti- Oxygen (168, Ciba Fine Chemicals Co., Ltd.) 0.5% and conductive carbon fiber (12K long carbon fiber, Taiwan Taili carbon fiber) 25.5% adopt twin-screw extruder to carry out melt blending extrusion granulation at 200~210 ℃, and then The above-mentioned granules are mixed after adding foaming agent HFC-245fa (Honeywell) 2% and foaming agent sodium bicarbonate (Tianjin Jinhui Taiya Chemical Reagent Co., Ltd.) 0.1% at room temperature, at 215 ° C, injection Under the condition of pressure of 40MPa and mold temperature of 30°C, inject samples or parts with an injection molding machine.

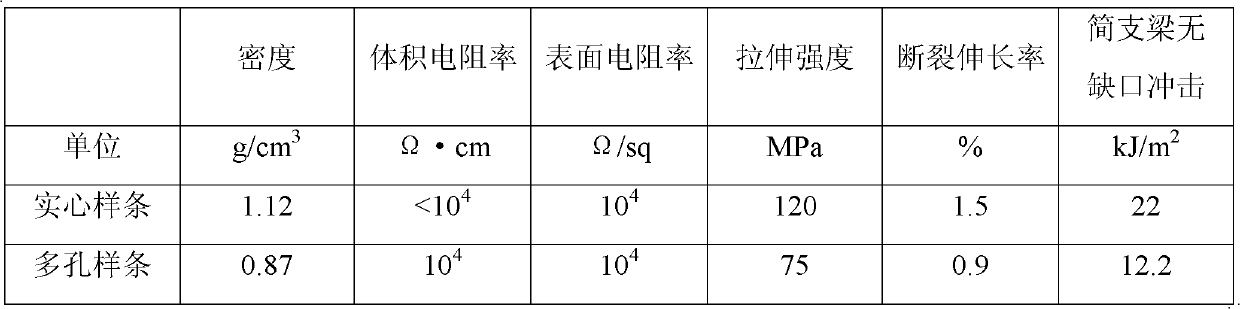

[0028] Below is the comparison of the performance detection data of solid spline (not using blowing agent) and porous spline (embodiment 1):

[0029] The performance detection result of table 1 embodiment 1

...

Embodiment 2

[0033] By weight percentage, take polystyrene (HIPS-424, Shanghai Secco Petrochemical Co., Ltd.) 74%, lubricant (Rome 2 type calcium stearate, Shanghai Aoke Chemical Co., Ltd.) 0.1%, disperse agent (TM932, Yizheng Tianyang Chemical Co., Ltd.) 0.5%, stabilizer (944, Ciba Fine Chemical Co., Ltd.) 0.1%, toughening agent (200B, Ningbo Nengzhiguang New Material Technology Co., Ltd.) 2.2% and antioxidant (1010, Ciba Specialty Chemicals Co., Ltd.) 0.1% and conductive carbon fiber (TR06Q, Japan Mitsubishi carbon fiber) 23% were carried out at 200 ~ 205 ° C using a twin-screw extruder for melt blending extrusion granulation, and then the above pellets At room temperature, add blowing agent HFC-245fa (Honeywell) 1.5% and blowing agent sodium bicarbonate (Tianjin Jinhui Taiya Chemical Reagent Co., Ltd.) 0.1% after mixing, at 210 ℃, injection pressure is 60MPa and Under the condition that the mold temperature is 55°C, inject samples or parts with an injection molding machine.

[0034] Be...

Embodiment 3

[0039] By weight percentage, take polystyrene (HIPS-424, Shanghai Secco Petrochemical Co., Ltd.) 87%, lubricant (Rome 2 type calcium stearate, Shanghai Aoke Chemical Co., Ltd.) 2.3%, disperse (TM932, Yizheng Tianyang Chemical Co., Ltd.) 0.5%, antioxidant (1010, Ciba Specialty Chemical Co., Ltd.) 0.2% and conductive carbon black (KetjenblackEC-300J, AkzoNobel) 10% at 200 ~ 205 ℃ Single-screw extruder carries out melt blending extruding granulation, then above-mentioned pellet is added foaming agent HFC-245fa (Honeywell) 3.5% and foaming agent sodium bicarbonate (Tianjin Jinhui Taiya Chemical Co., Ltd. Reagent Co., Ltd.) 0.1% after mixing, under the conditions of 210°C, injection pressure of 75MPa and mold temperature of 65°C, inject samples or parts with an injection molding machine.

[0040] Below is the comparison of performance detection data of solid spline (not using blowing agent) and porous spline (embodiment 3):

[0041] The performance detection result of table 3 embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com