Energy conservation and emission reduction process for producing p-xylene through alkylation of tolylcarbinol

A para-xylene, energy saving and emission reduction technology, applied in the chemical industry, organic chemistry, sustainable manufacturing/processing, etc. Effects of flash temperature, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. Take the 100,000 tons of PX / year industrial plant as an example to further illustrate the technology of the present invention.

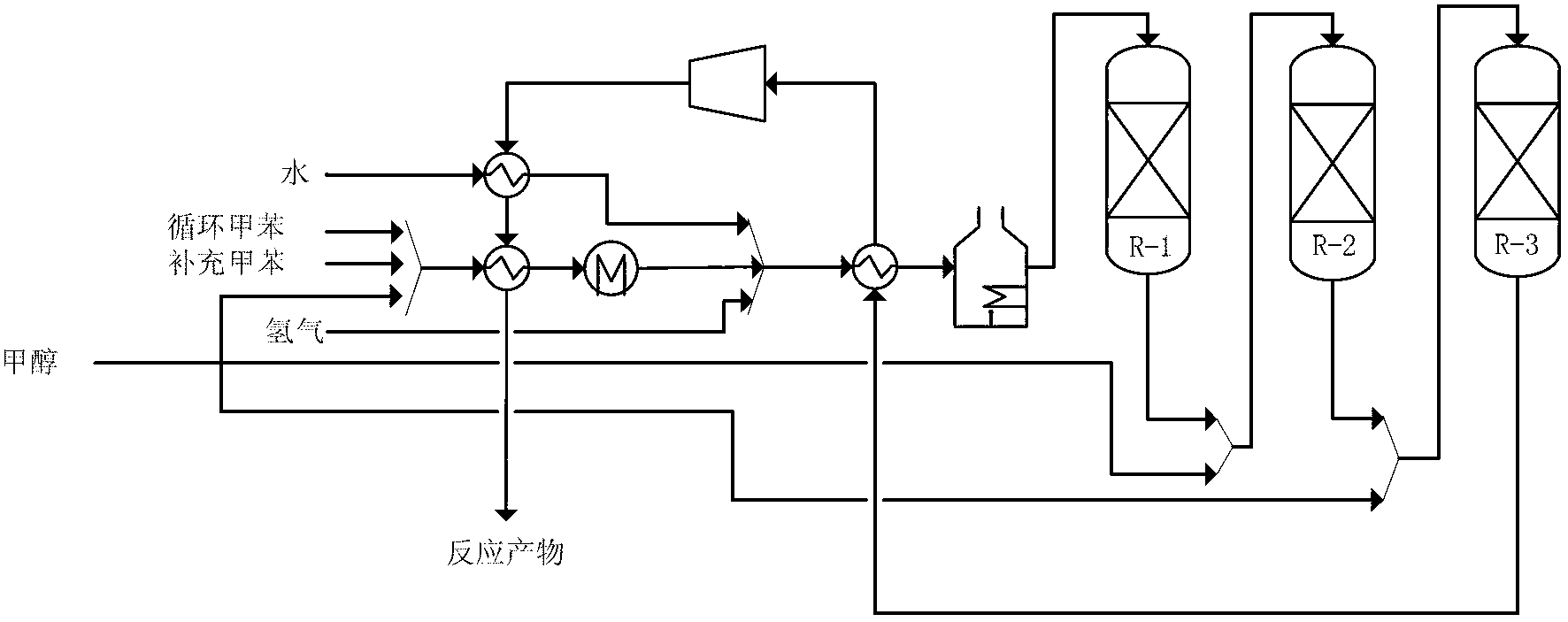

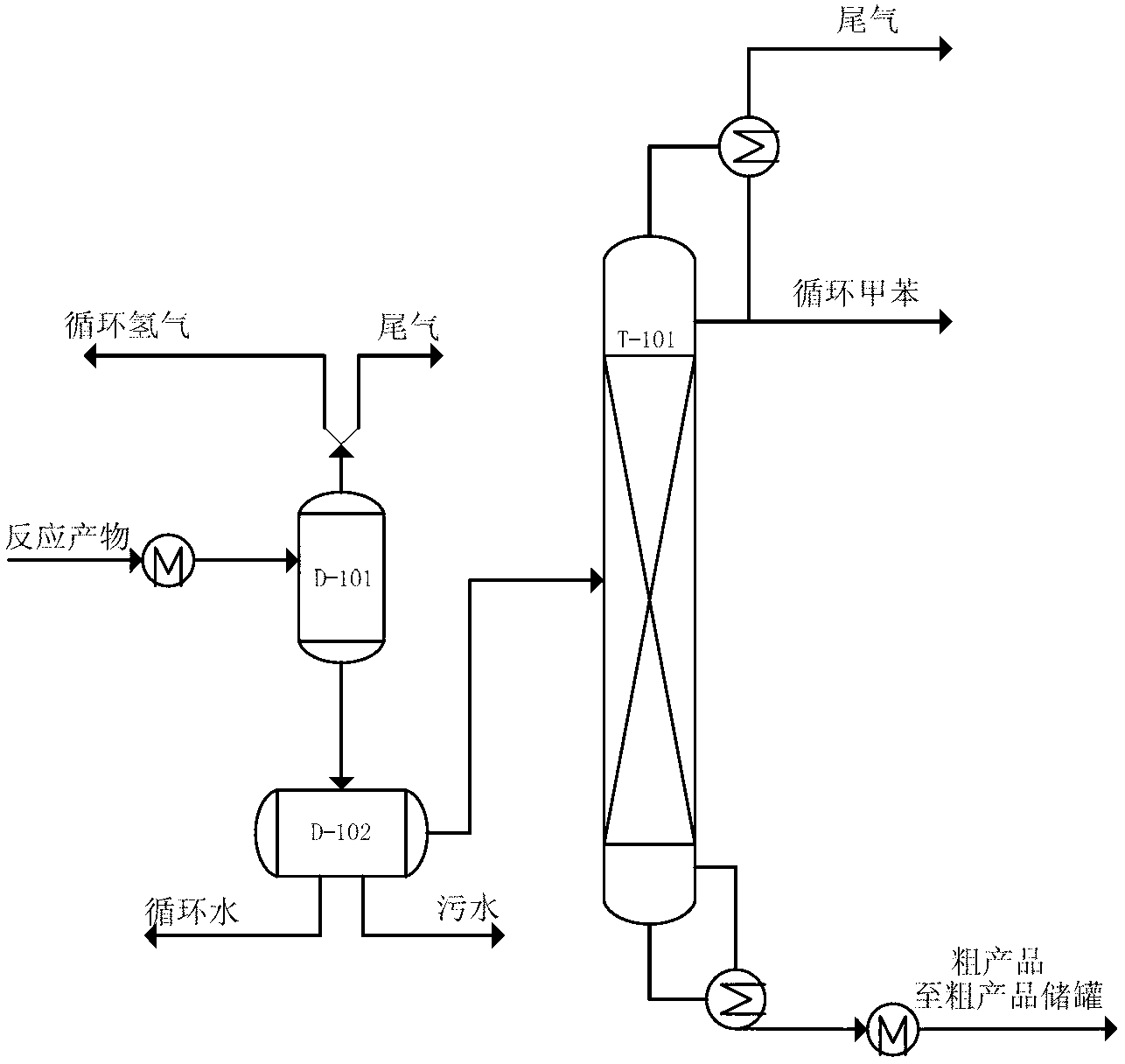

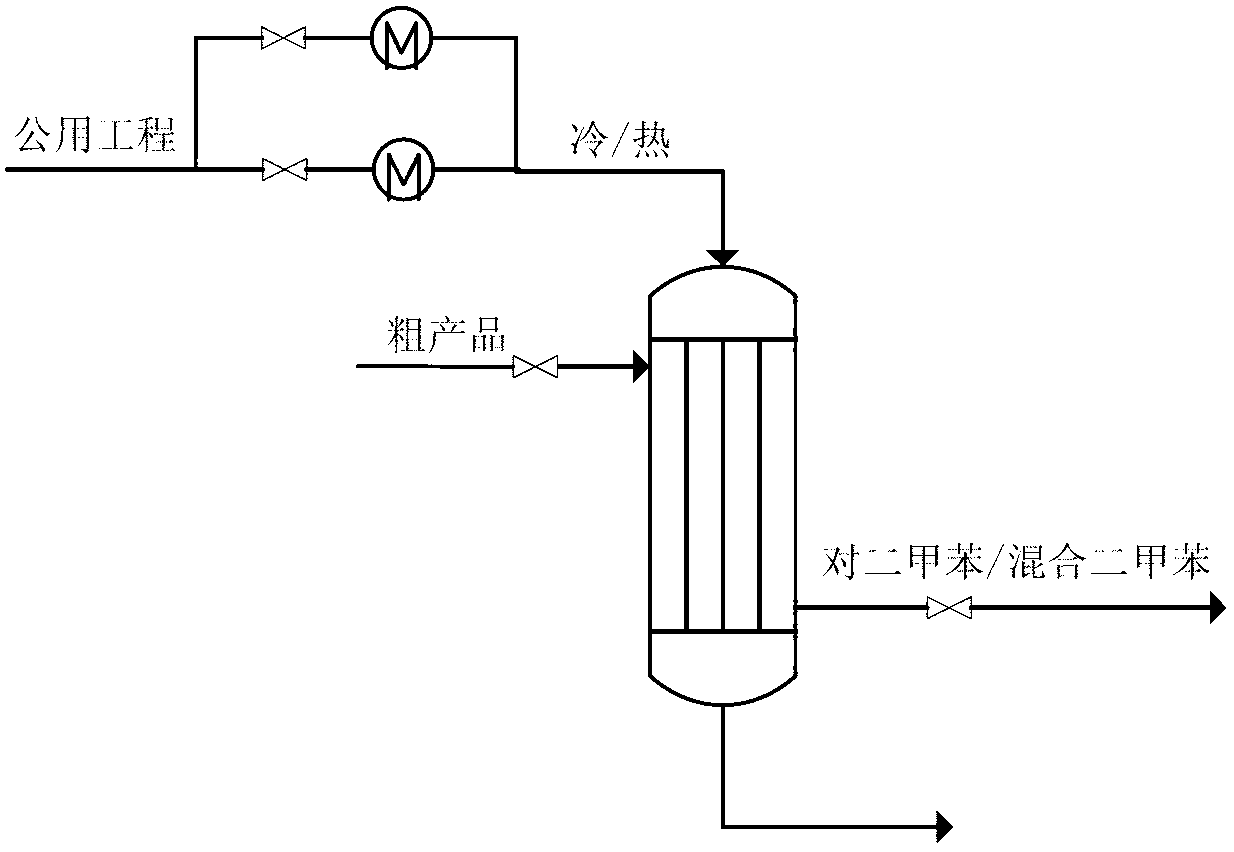

[0021] Such as figure 1 As shown, the raw materials flowing into the reactor are toluene with a mass flow rate of 45.14t / h and methanol with a mass flow rate of 2.24t / h. After the two are mixed, they are heated and vaporized, and then fully mixed with circulating hydrogen, supplementary hydrogen and water vapor. The reaction product can be heated to 455°C after heat exchange, and then heated to the reaction temperature with a heating furnace, and then reacted in the fixed bed reactor R1. The raw material temperature at the reactor inlet is 460°C, and the reaction pressure is 0.5MPa. The temperature of the product at the outlet of R1 is 475°C, and it is mixed with methanol with a mass flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com