Method for directionally preparing benzene by utilizing xylogen

A lignin and directional conversion technology, which is applied in the fields of cracking polyarylate compounds on the bond between six-membered aromatic rings to produce hydrocarbons, bulk chemical production, organic chemistry, etc., can solve the unseen controllable conversion technology of lignin, etc. problems, to achieve the effect of recycling and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Depolymerize lignin into aromatic monomers

[0020] In the process of this example, the lignin raw material was purchased from Hefei Lanxu Biotechnology Co., Ltd. The main elements in the lignin raw material are carbon, hydrogen and oxygen (the element ratio is C:H:O=62.55:5.83:31.62). The catalyst for lignin depolymerization is 15 wt%Ni / HZSM-5 modified zeolite catalyst. The preparation steps of the catalyst are: weighing 37.5 g of nickel nitrate hexahydrate, adding 100 mL of deionized water to form a nickel nitrate solution; , Shake the solution to cover the powder of ZSM-5, let it soak for 24 hours, then evaporate the water in the solution in an 80-degree water bath, then dry it in an oven at 120 degrees, and then sinter it in a muffle furnace at 550 degrees for 6 hours . Then the prepared 15 wt%Ni / HZSM-5 catalyst and binder (kaolin or Tianjing powder) are mixed and ground to obtain mixed powder, wherein the binder accounts for 10 wt% of the total mixed ...

Embodiment 2

[0026] Example 2 Directed conversion of aromatic monomers to benzene

[0027] In the present embodiment process, reactant raw material adopts in embodiment 1 at 600 o C and current are aromatic monomer mixtures produced by catalytic depolymerization of lignin under the condition of 0A. The catalyst is a 10 wt % Re / Y rhenium-containing zeolite catalyst. The preparation steps of the catalyst are as follows: weighing 16g of rhenium nitrate, adding 100mL of deionized water to configure a rhenium nitrate solution; Make the solution submerge the powder of HY zeolite, let it stand for immersion for 24 hours, evaporate the moisture in the solution in an 80-degree water bath, then dry it in an oven at 120 degrees, and then sinter it in a muffle furnace at 550 degrees for 6 hours. Then the prepared 10wt% Re / Y type zeolite catalyst and binding agent (kaolin or Tianjing powder) are mixed and ground in a certain proportion to obtain mixed powder, wherein the binding agent accounts for ...

Embodiment 3

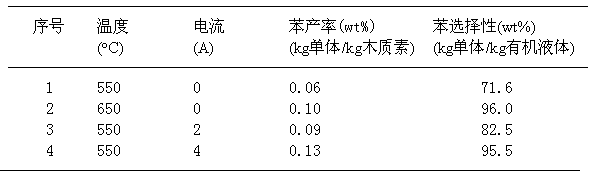

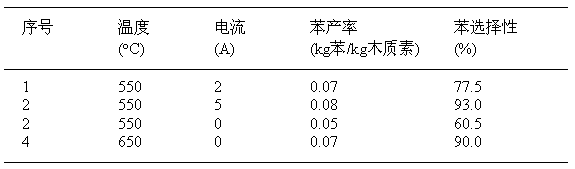

[0034] Example 3 A coupled approach for the depolymerization of lignin and the directed conversion of aromatic monomers to benzene

[0035] In the process of this example, the lignin raw material is derived from the lignin sample of Hefei Lanxu Biotechnology Co., Ltd., and the main elements in the lignin raw material are carbon, hydrogen and oxygen elements (the element ratio is C:H:O=62.55:5.13 :32.30). The lignin depolymerization catalyst was a commercially available HZSM-5 zeolite with a silicon-to-aluminum ratio of 100, and the aromatic monomer conversion catalyst was a commercially available 16% ReY catalyst. The two catalysts were mixed in a ratio of 1:1, and 10wt% kaolin was added as a binder. That is, a finished bifunctional catalyst product with lignin depolymerization and directional conversion of monomers into benzene is obtained.

[0036] The catalytic conversion reactor used is a cylindrical fixed-bed catalytic reactor with external heating and insulation laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com