Piezoelectric material and preparation method thereof

A piezoelectric material and binder technology, which can be used in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., and can solve the problems of high resonance impedance coupling coefficient, low mechanical Q value, high sensitivity, etc. , to achieve the effect of improving piezoelectric performance, reducing Qm value, and improving piezoelectric coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

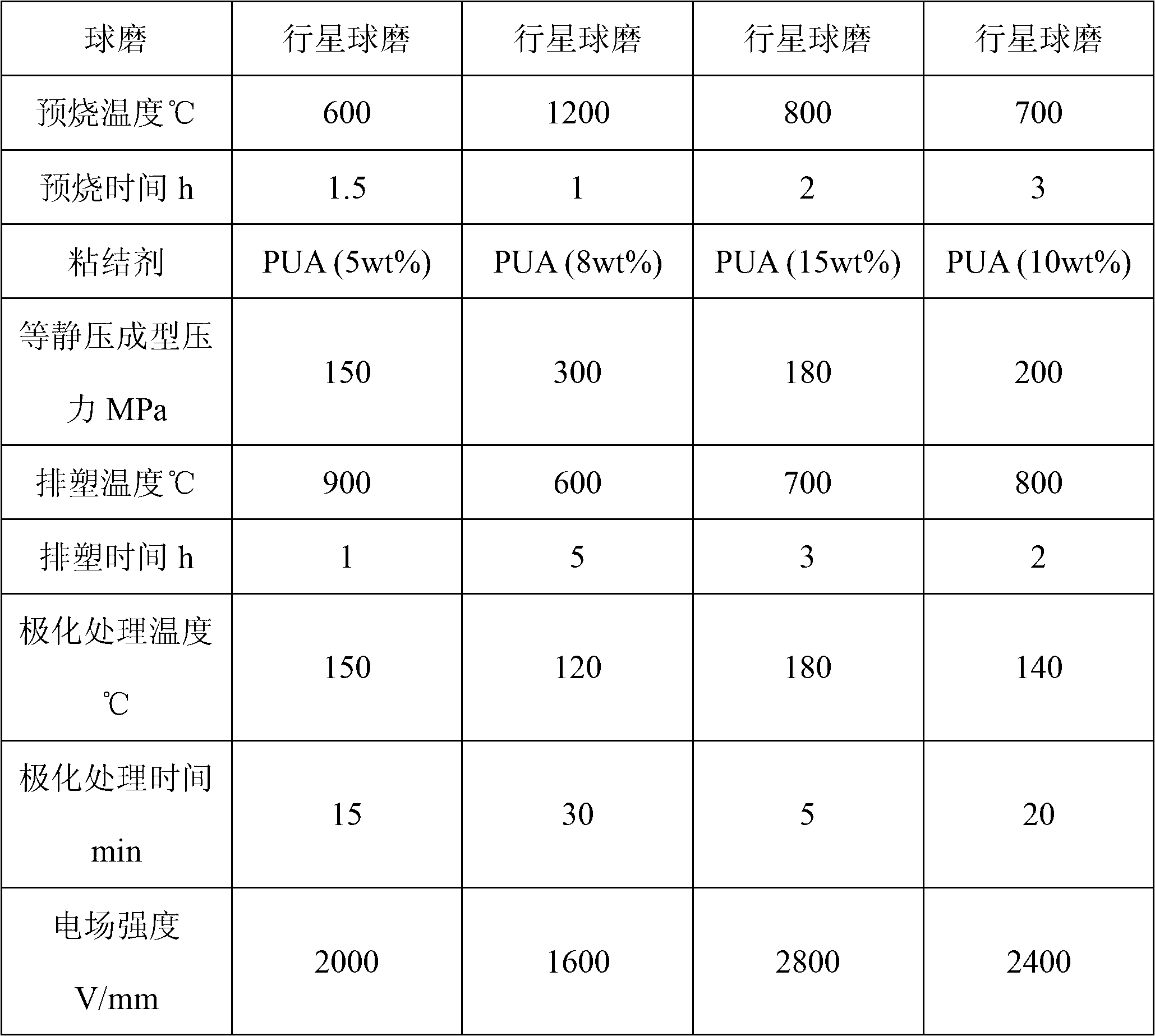

Embodiment 1

[0050] (1) Select compounds containing the required elements (PbO, BaO, MgO, NiO, TiO 2 , ZrO 2 , Nb 2 o 5 ), batching according to the chemical composition of the compound to be prepared, pre-pressing after ball milling, pre-calcining, rolling ball milling again, to obtain substance a;

[0051] (2) Adding a binder to substance a to granulate, forming and discharging plastic, and then sintering to obtain substance b;

[0052] (3) Substance b is subjected to polarization treatment to obtain a piezoelectric material with the following chemical composition: Pb 0.98 Ba 0.01 Mg 0.01 [(Ni 1 / 3 Nb 2 / 3 ) 0.1 · Zr 0.6 · Ti 0.3 ]O 3 .

[0053] The mass of the compound containing the desired elements can be calculated from the chemical composition of the final piezoelectric material.

Embodiment 2

[0055] (1) Select compounds containing the required elements (lead carbonate, strontium carbonate, magnesium carbonate, NiO, Nb 2 o 5 , zirconium carbonate, titanium nitride), according to the chemical composition of the compound to be prepared, the ingredients are pre-pressed after ball milling, pre-calcined, and ball milled again to obtain substance a;

[0056] (2) Adding a binder to substance a to granulate, forming and discharging plastic, and then sintering to obtain substance b;

[0057] (3) Substance b is subjected to polarization treatment to obtain a piezoelectric material with the following chemical composition: Pb 0.9 Sr 0.05 Mg 0.05 [(Ni 1 / 3 Nb 2 / 3 ) 0.7 · Zr 0.2 · Ti 0.1 ]O 3 .

[0058] The mass of the compound containing the desired elements can be calculated from the chemical composition of the final piezoelectric material.

Embodiment 3

[0060] (1) Select compounds containing the required elements (lead carbonate, lanthanum carbonate, barium carbonate, NiO, Nb 2 o 5 , titanium nitrate, zirconium nitrate), ingredients according to the chemical composition of the compound to be prepared, pre-pressed after ball milling, pre-calcined, rolling ball milling again, to obtain substance a;

[0061] (2) Adding a binder to substance a to granulate, forming and discharging plastic, and then sintering to obtain substance b;

[0062] (3) Substance b is subjected to polarization treatment to obtain a piezoelectric material with the following chemical composition: Pb 0.95 La 0.02 Ba 0.03 [(Ni 1 / 3 Nb 2 / 3 ) 0.2 · Zr 0.1 · Ti 0.7 ]O 3 .

[0063] The mass of the compound containing the desired elements can be calculated from the chemical composition of the final piezoelectric material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com