Cellular turntable driving type spherical fruit and vegetable breaking-cutting machine

A driving and honeycomb technology, applied in metal processing, etc., can solve problems such as difficult clamping and positioning of spherical fruits and vegetables, increase in initial investment, later use and maintenance costs, fruit and vegetable bumps and extrusion damage, etc., to reduce fruit and vegetable bumps and extrusion damage, avoiding personal injury accidents, and avoiding the effects of missing and overcutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0030] refer to figure 1 , The main frame 1 of this embodiment is equipped with an overhead feeding device, a honeycomb breaking device, a discharging device and a power transmission device.

[0031] refer to figure 1 and Figure 9 , the overhead feeding device of the present embodiment includes feeding hopper 4, feeding hopper support I 2, feeding hopper support II 3 and feeding hopper support III 6, feeding hopper 4 passes through feeding hopper support I 2, feeding hopper support II 3 and The feeding hopper support III 6 is fixed on the main frame 1 table top, and there are 3 feeding hopper outlets 41 at intervals of 120° at the bottom of the feeding hopper 4, separated by 3 feeding hopper legs 42 between the feeding hopper outlets 41.

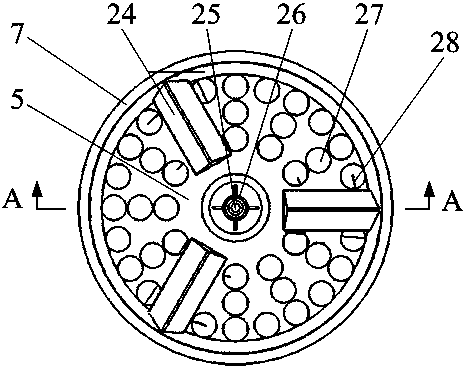

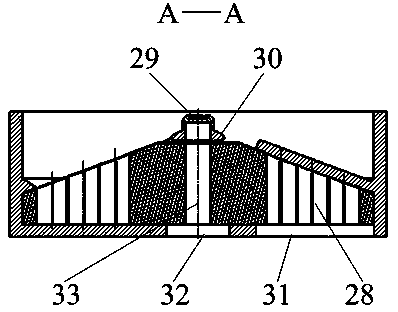

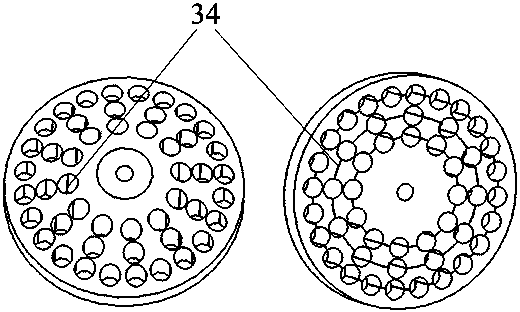

[0032] refer to Figure 1 to Figure 7 , the honeycomb type breaking and cutting device of the present embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com