High temperature brazing filler metal for brazing non-oxide ceramic and composite material as well as preparation method of high temperature brazing filler metal

A non-oxide, high-temperature solder technology, applied in the direction of welding/cutting media/materials, welding equipment, welding media, etc., can solve problems such as unreliable performance, avoid the formation of brittle phases, promote interfacial metallurgical reactions, and improve the melting point suitable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

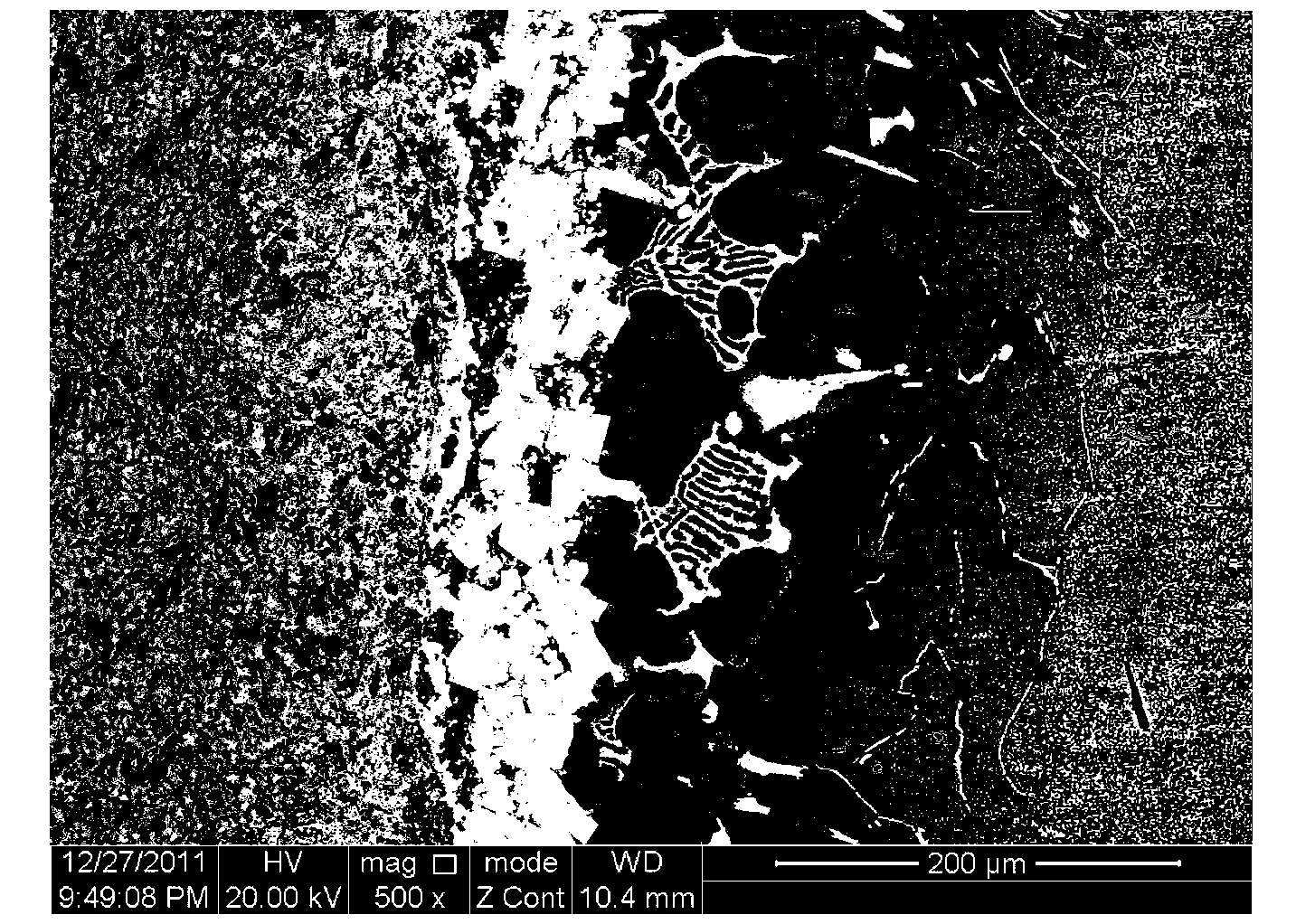

Image

Examples

specific Embodiment approach 1

[0013] Specific Embodiment 1: A kind of high-temperature solder for brazing non-oxide ceramics and composite materials in this embodiment is composed of 47 to 52 parts of Ni, 25 to 28 parts of Cr, 18 to 21 parts of Nb, 0~2 parts of B, 0~2 parts of Ti and 0~6 parts of W.

[0014] The brazing filler metal of this embodiment has a suitable melting point and good wettability for brazing connection of non-oxide ceramics and their composite materials with various high-temperature alloys, and can meet the requirement of brazing joints at 800°C. Moreover, the brazing filler metal of this embodiment does not contain precious metals such as Ag and Pd, and the cost is low. Compared with other commercial nickel-based solders, the nickel-based solder used in the present invention does not rely on high content of Si or B to reduce the melting point of the solder, but relies on Ni, Cr, Nb ternary eutectic reaction in brazing The liquid phase is formed at high temperature, and the content an...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the purity of Ni is 99.0%~99.9%, the purity of Cr is 99.0%~99.9%, the purity of Nb is 99.0%~99.9%, The purity of B is 99.0%~99.9%, the purity of Ti is 99.0%~99.9% and the purity of W is 99.0%~99.9%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiments one to two is that the high-temperature solder is composed of 48 parts of Ni, 25.5 parts of Cr, 18.5 parts of Nb, 2 parts of B, 2 parts by mass percentage. Parts of Ti and 6 parts of W. Others are the same as the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com