Manufacturing method for easily pickled steel with low yield ratio by thin slab casting and rolling

A technology of thin slab continuous casting and low yield ratio, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of increasing the thickness of iron oxide scale, difficult pickling, and increasing the difficulty of pickling pickled steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The manufacturing method of the thin slab continuous casting and rolling low-yield-strength-ratio easy pickling steel of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

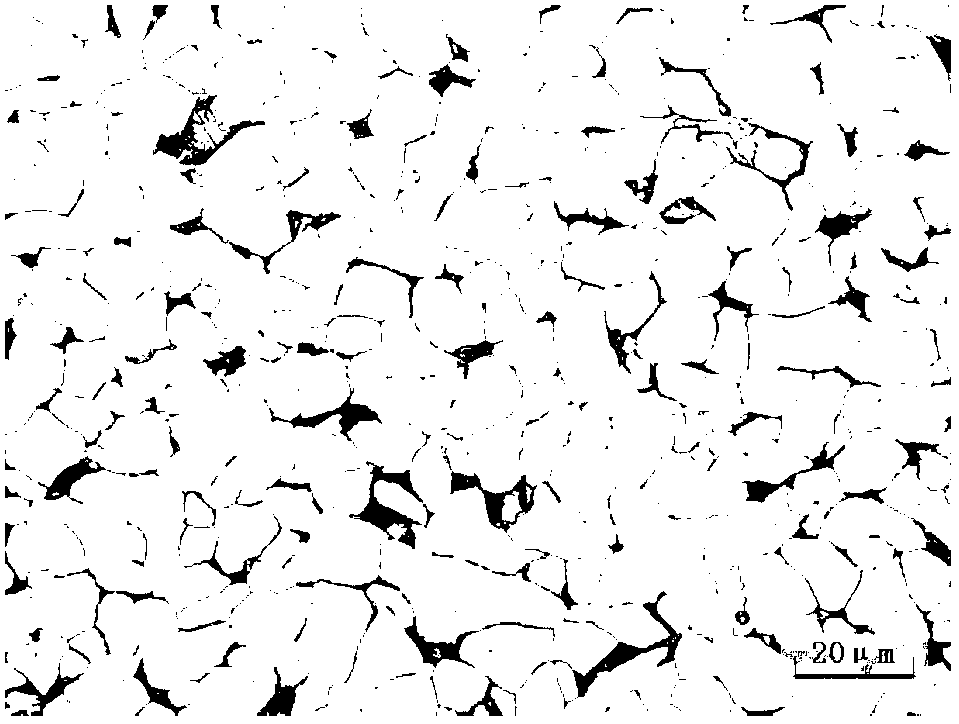

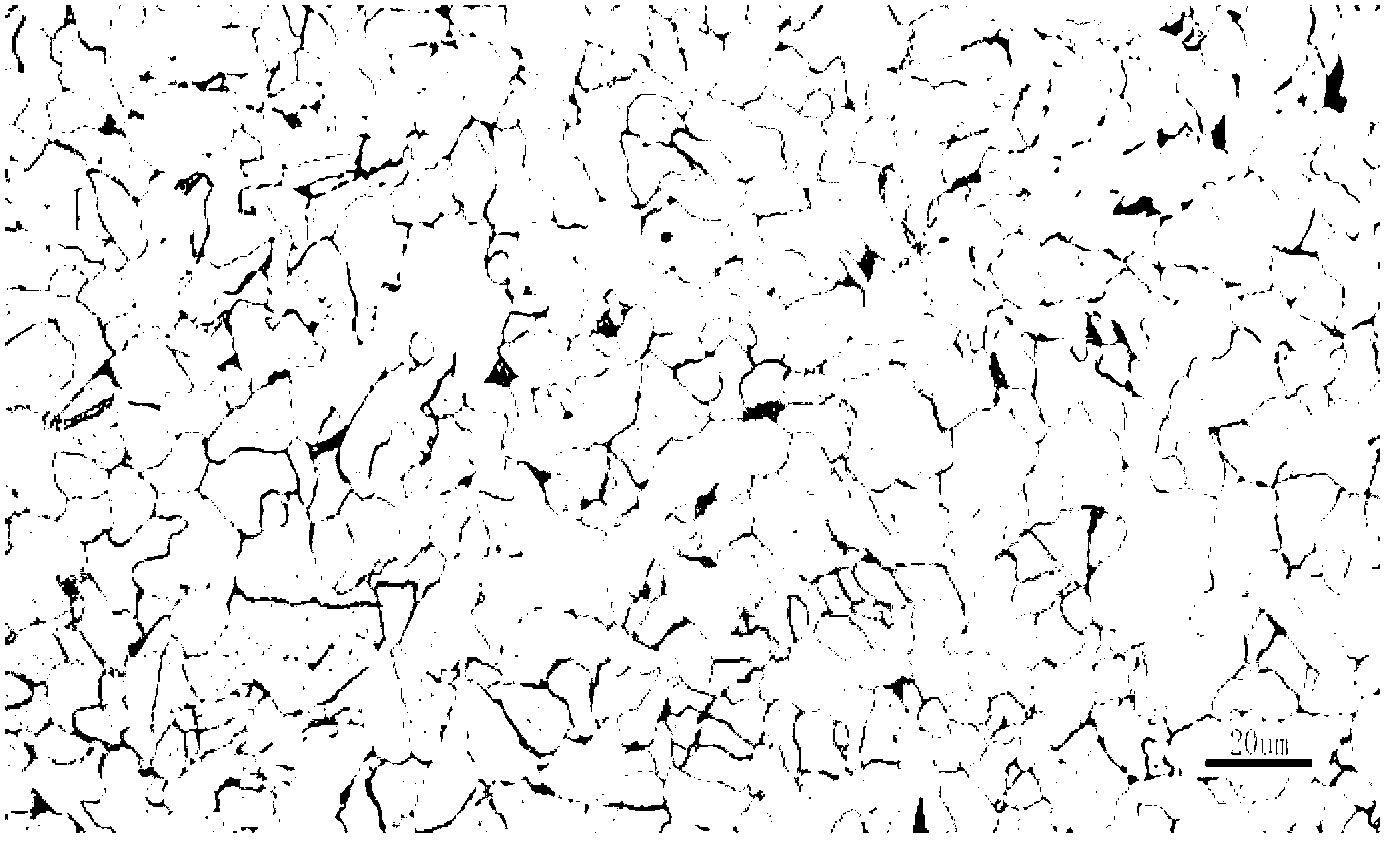

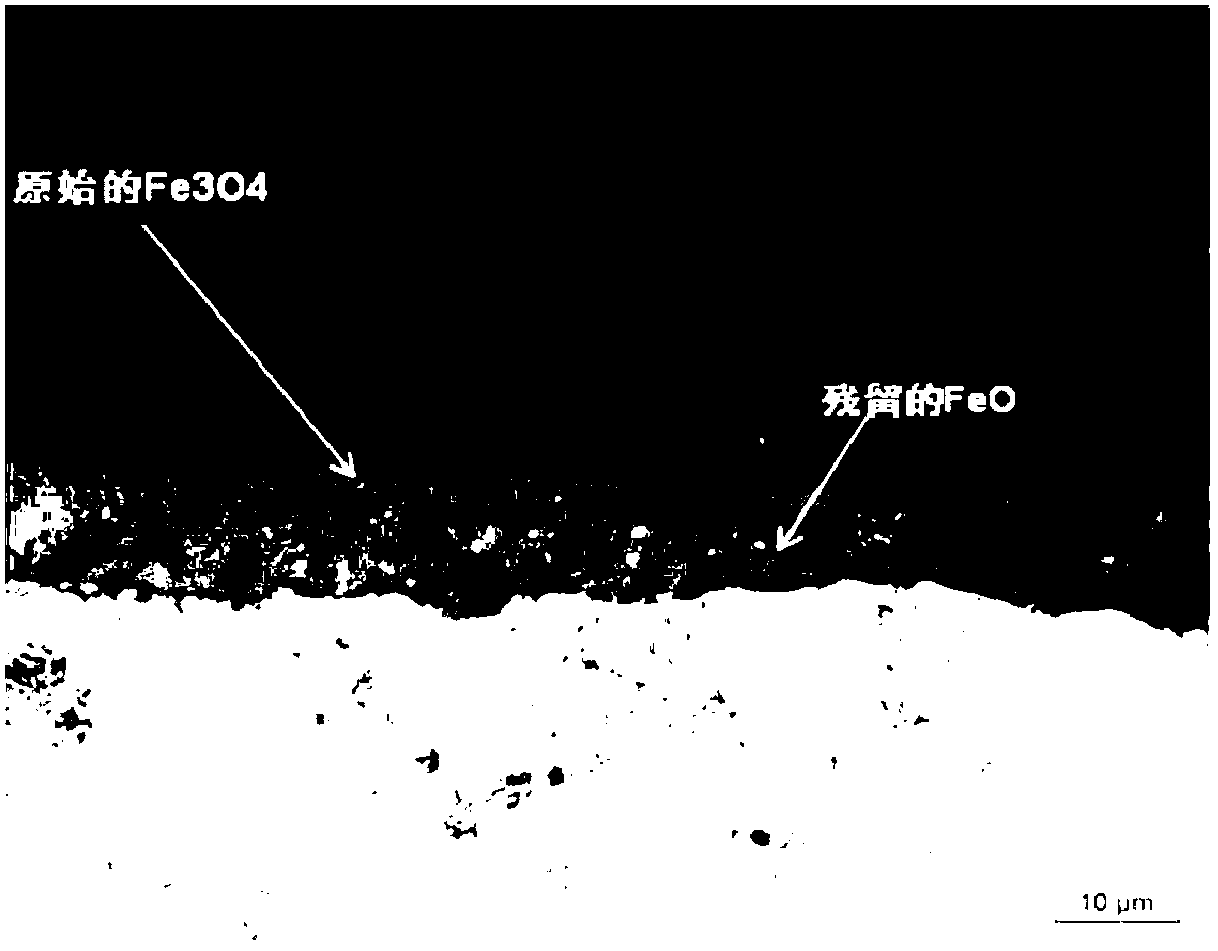

[0019] The composition of the steel in specific embodiments of the present invention (shown in Table 1), the reduction rate of each pass in the manufacturing process (shown in Table 2), the rolling and cooling process control (shown in Table 3), wherein the comparative examples are The current conventional composition and process of thin slab continuous casting and rolling pickling steel. The typical metallographic photograph of embodiment 1 of the present invention is as figure 1 Shown, the typical metallographic photograph of comparative example is as figure 2 shown. In addition, the photo of the typical oxide scale morphology of Example 1 of the present invention is as follows image 3 As shown, the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com