Separator for non-aqueous electrolyte secondary battery and non-aqueous electrolyte secondary battery using the same

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte batteries, separators/films/diaphragms/spacer components, battery components, etc. Problems such as clogging and operability decline, etc., to achieve a good capacity maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

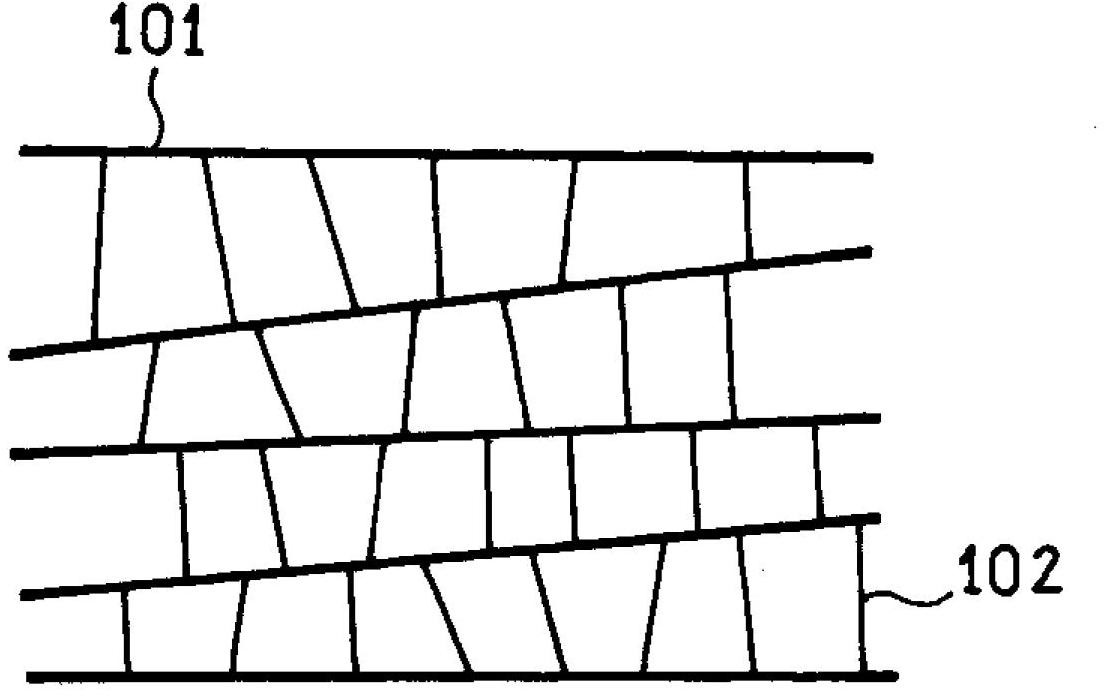

[0124] (1) Fabrication of positive electrode 5

[0125] In an appropriate amount of N-methyl-2-pyrrolidone, 100 parts by mass of lithium cobaltate as a positive electrode active material, 2 parts by mass of acetylene black as a conductive agent, and 3 parts by mass of polyvinylidene fluoride resin as a binder are added and Kneading is carried out to prepare a slurry-like mixture. This slurry was continuously applied to both surfaces of a strip-shaped aluminum foil (thickness: 15 μm) serving as a positive electrode current collector. Among them, the exposed part of the aluminum foil for connecting the positive electrode lead 5a was left. The coating film of the dried mixture is rolled together with the positive electrode current collector under a linear pressure of 1000kgf / cm (9.8kN / cm) for 2 to 3 times, and the thickness of the coating film is adjusted to 180μm to make a positive electrode active material Floor. Then, the current collector having the positive electrode acti...

Embodiment 2)

[0151] A battery was produced in the same manner as in Example 1 except for using the separator described below.

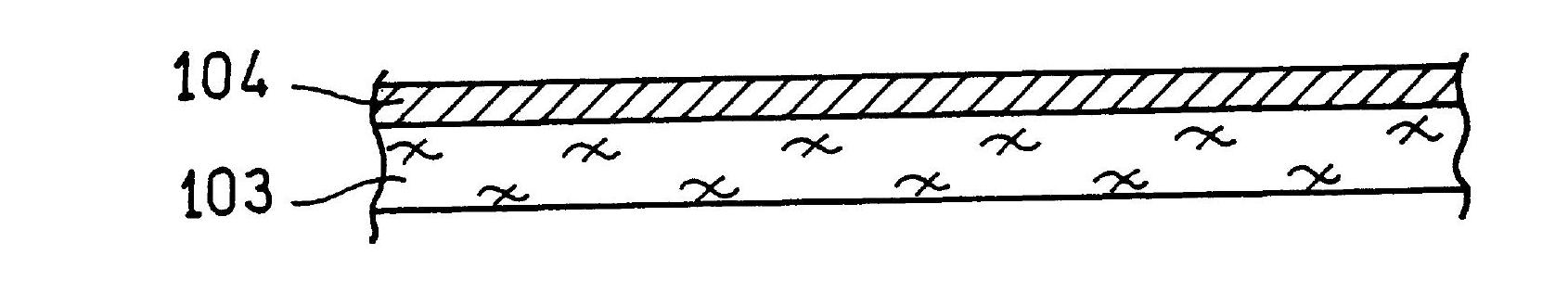

[0152] First, various polyethylene porous membranes with an average distance between extended chain crystals of 3.0 μm or more and less than 5.0 μm and an average distance between folded chain crystals of 0.5 μm or more but less than 0.7 μm were prepared (compared to Table 1). No.6 same structure). The thickness of the polyethylene porous membrane was set to 20 μm or 17 μm. For a polyethylene porous membrane with a thickness of 20 μm, various polyethylene porous membranes are produced by appropriately changing the conditions of the manufacturing process so that they have the same structure as No. 6 in Table 1, and the final Glyer air permeability and porosity changes.

[0153] In addition, an NMP solution of aramid was coated on one side of a polyethylene porous membrane having a thickness of 17 μm. Thus, a separator having a two-layer structure of a polyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear shrinkage | aaaaa | aaaaa |

| apparent porosity | aaaaa | aaaaa |

| linear shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com