Concrete composition

A technology of composition and compound, which is applied in the field of hydraulic material composition, can solve the problems of freeze-thaw resistance deterioration, increase, hindering the market popularization of shrinkage reducing agents for hydraulic materials, etc., and achieve excellent freeze-thaw resistance and inhibition strength Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

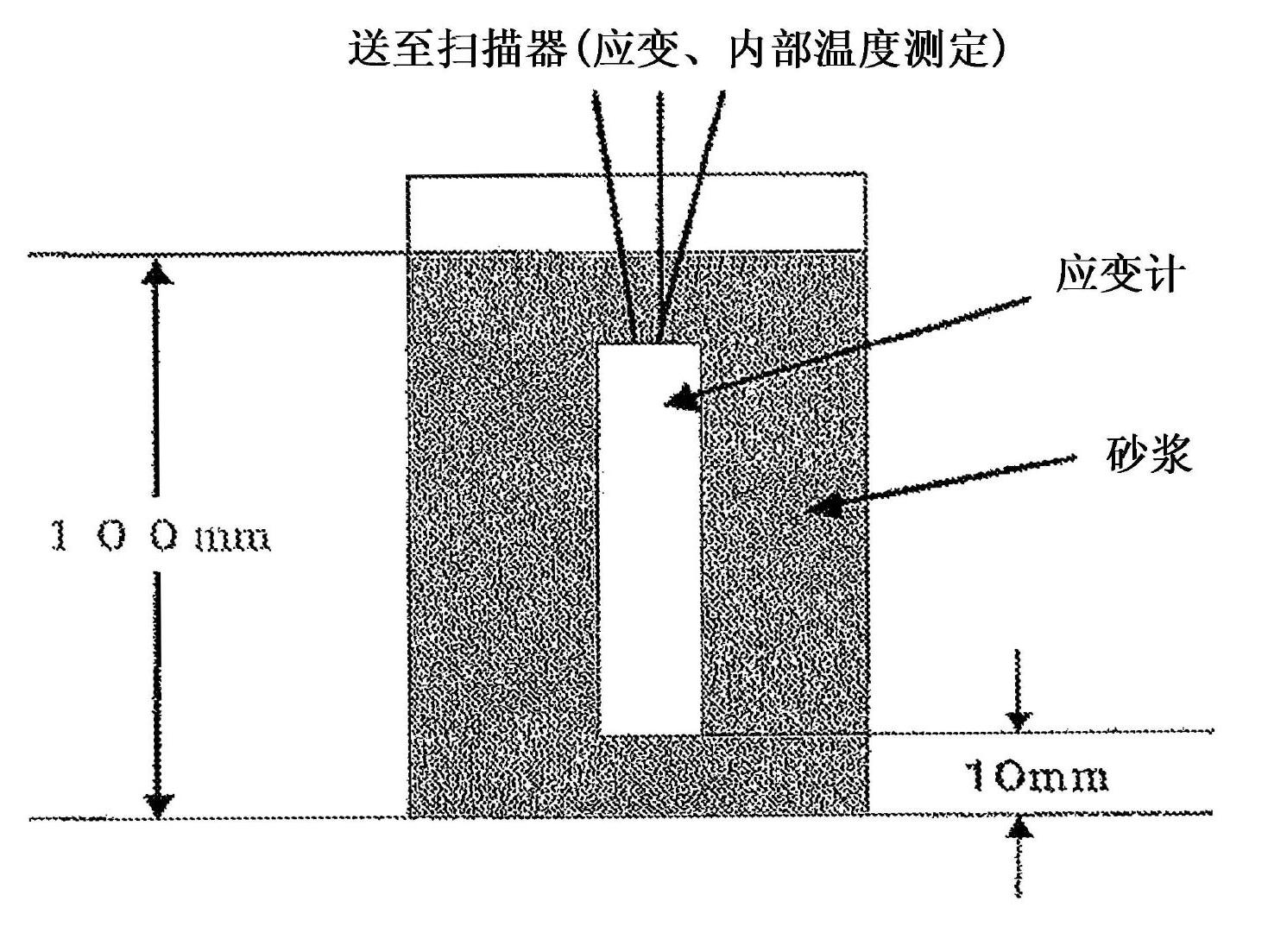

Image

Examples

preparation example Construction

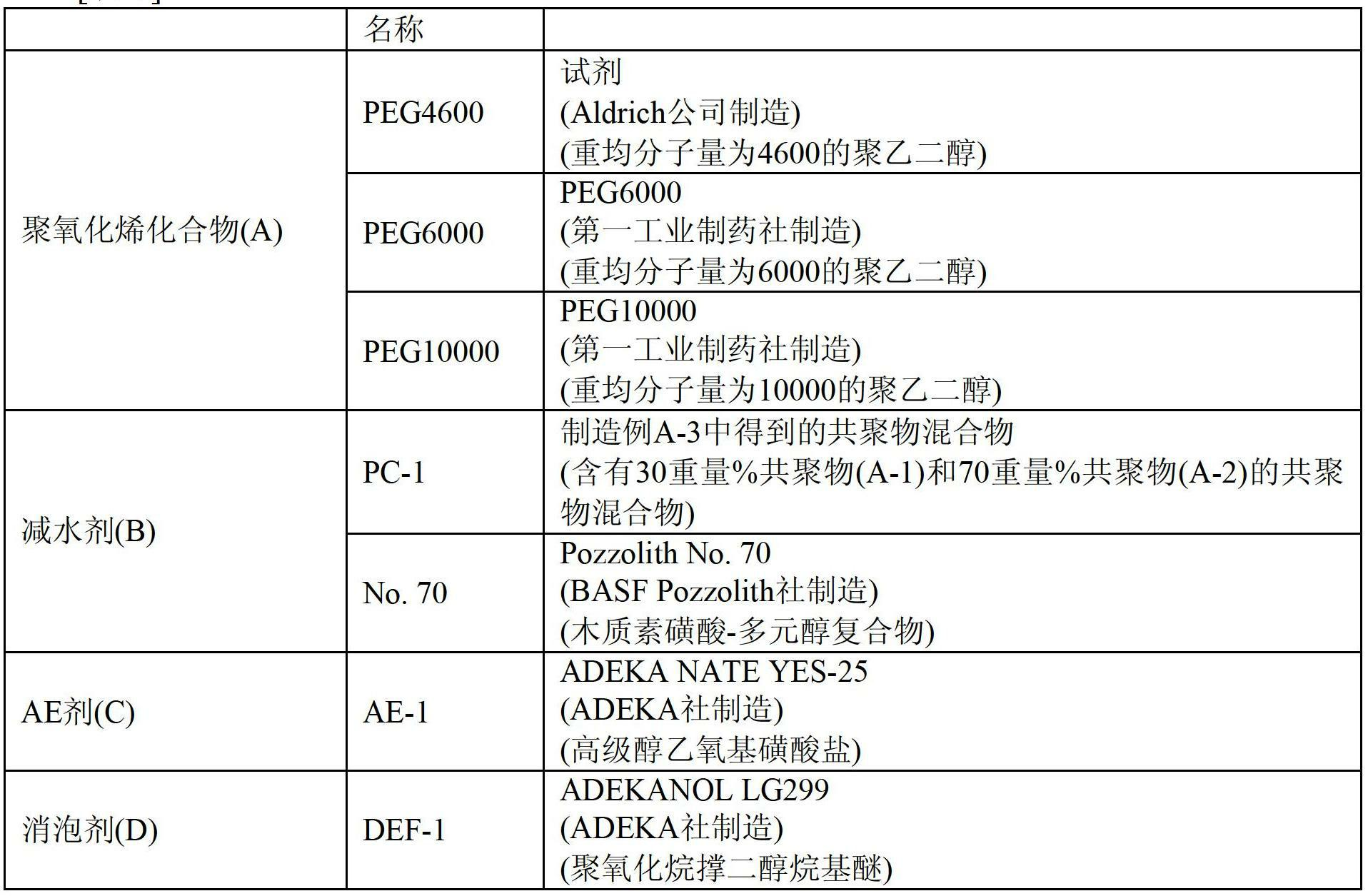

[0122] "3. Preparation of shrinkage reducing agent for hydraulic materials"

[0123] The shrinkage reducing agent for hydraulic materials can be produced by any appropriate method. For example, polyoxyalkylene compound (A) can be used as an essential component, and if necessary, it can be mixed with water reducer (B), AE agent (C), defoamer (D), polyoxyalkyl ether ( E), at least one of the pH adjuster and any other components are mixed by any appropriate method. The order of mixing can be in any suitable order.

[0124] The shrinkage reducing agent for hydraulic materials has both excellent shrinkage reducing function and excellent freeze-thaw resistance. Since the shrinkage reducing agent for hydraulic materials contains a high concentration of polyoxyalkylene compound (A), the polyoxyalkylene compound (A) has excellent stability over time, so it does not separate and precipitate and has excellent compatibility. Therefore, water / cement The application range of the ratio is...

Embodiment

[0126] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited to these examples. It should be noted that, unless otherwise specified, "parts" and "%" in the examples are based on weight.

[0127] "GPC Molecular Weight Determination Conditions"

[0128] Column used: TSKguardcolumn SWXL+TSKgelG4000SWXL+G3000SWXL+G2000SWXL manufactured by TOSOH

[0129] Eluent: 115.6 g of sodium acetate trihydrate was dissolved in a mixed solvent of 10999 g of water and 6001 g of acetonitrile, and the pH was further adjusted to 6.0 with 30% aqueous sodium hydroxide solution, and the resulting eluent solution was used.

[0130] Injection volume: 100 μL 0.5% eluent solution

[0131] Eluent flow rate: 0.8mL / min

[0132] Column temperature: 40°C

[0133] Standard substance: polyethylene glycol, weight average molecular weight (Mw) 272500, 219300, 85000, 46000, 24000, 12600, 4250, 7100, 1470.

[0134] Calibration curve orde...

Embodiment A-1~ Embodiment A-3

[0233] "Example A-1 to Example A-3, Comparative Example A-1"

[0234] (mix)

[0235] With the mixing ratio shown in Table 2, each material was measured so that the kneading amount would be 30 L, and the material was kneaded using a disc mixer. In addition, regarding cement, ordinary Portland cement (specific gravity 3.16) manufactured by Pacific Cement Co., Sumitomo Osaka Cement Co., Ltd., and Ube Mitsubishi Cement Co., Ltd. was mixed equally and used. A mixture of Kakegawa land sand and Kimitsu land sand at a weight ratio of Kakegawa land sand / Kitsu land sand = 80 / 20 was used as fine aggregate, and Ome hard sandstone was used as coarse aggregate.

[0236] [Table 2]

[0237]

[0238] (mixing of materials)

[0239] Put the coarse aggregate and half of the fine aggregate used into the mixer, stop the rotation after 5 seconds of dry mixing, and put in cement and the remaining fine aggregate. After a further 5 seconds of dry mixing, stop the rotation again, add water contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com