Method for preparing Al mixed with ZnO nanosheet array by adopting pulsed electromagnetic field

A pulsed electromagnetic field and nanosheet array technology, which is applied in photosensitive equipment, photovoltaic power generation, etc., can solve the problems of small height/thickness ratio, difficult control of ZnO nanosheet structure and low order degree, and achieve high verticality, Facilitate electron transport and increase absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

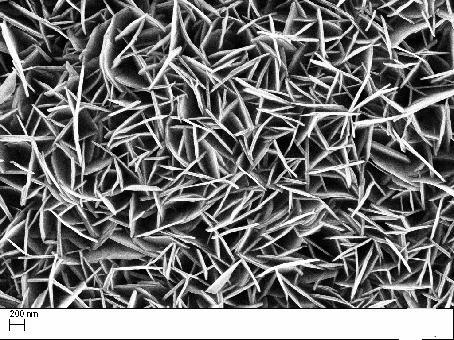

[0029] Such as figure 1 As shown, the method for preparing Al-doped ZnO nanosheet arrays is as follows:

[0030] 1. Put the FTO conductive glass sheet (size: 20×20×3mm) into an ultrasonic cleaner at a temperature of 80°C for 5 minutes, take it out, rinse it with deionized water, and dry it in a vacuum oven for 5 hours;

[0031] 2. Using ethylene glycol methyl ether as a solvent, prepare mixed solution I with 2ml zinc acetate, 2ml ethanolamine and 15ml ethylene glycol methyl ether;

[0032] 3. Take 3ml of the prepared mixed solution I and drop it on the conductive glass sheet. After coating the solution evenly with a glue homogenizer, place the FTO conductive glass sheet coated with the mixed solution in a tubular heating furnace for heat treatment and heat it to 320°C. , keep warm for 18min, and cool to room temperature;

[0033] 4. Repeat the third step 4 times to obtain a dense and uniform ZnO film on the FTO conductive glass sheet;

[0034] 5. Add 0.01mol aluminum nitrat...

Embodiment 2

[0038] 1. Put the FTO conductive glass sheet (size: 20×20×3mm) in an ultrasonic cleaner at a temperature of 75°C for 4 minutes, take it out, rinse it with deionized water, and dry it in a vacuum oven for 4 hours;

[0039] 2. Using ethylene glycol methyl ether as a solvent, prepare mixed solution I with 3ml zinc acetate, 4ml ethanolamine and 24ml ethylene glycol methyl ether;

[0040] 3. Take 6ml of the prepared mixed solution I and drop it on the conductive glass sheet. After coating the solution evenly with a glue homogenizer, place the FTO conductive glass sheet coated with the mixed solution in a tubular heating furnace for heat treatment and heat it to 300°C. , keep warm for 15min, and cool to room temperature;

[0041] 4. Repeat the third step 5 times to obtain a dense and uniform ZnO film on the FTO conductive glass sheet;

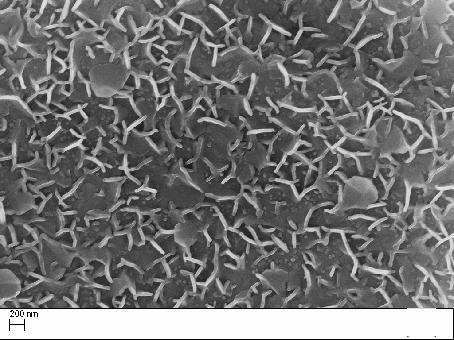

[0042]5. Add 0.01mol aluminum nitrate, 0.49mol zinc nitrate and 0.5mol hexamethylenetetramine to 25L deionized water to prepare mixed solution II, ...

Embodiment 3

[0045] 1. Put the FTO conductive glass sheet (size: 20×20×3mm) in an ultrasonic cleaner at a temperature of 85°C for 6 minutes, take it out, rinse it with deionized water, and dry it in a vacuum oven for 6 hours;

[0046] 2. Using ethylene glycol methyl ether as a solvent, prepare mixed solution I with 4ml zinc acetate, 6ml ethanolamine and 31ml ethylene glycol methyl ether;

[0047] 3. Take 12ml of the prepared mixed solution I and drop it on the conductive glass sheet. After coating the solution evenly with a glue homogenizer, place the FTO conductive glass sheet coated with the mixed solution in a tubular heating furnace for heat treatment and heat it to 340°C , keep warm for 20min, and cool to room temperature;

[0048] 4. Repeat the third step 3 times to obtain a dense and uniform ZnO film on the FTO conductive glass sheet;

[0049] 5. Add 0.01mol aluminum nitrate, 0.32mol zinc nitrate and 0.33mol hexamethylenetetramine to 13.2L deionized water to prepare mixed solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com