Supported copper-manganese-water-gas shift catalyst and preparation method thereof

A technology for shifting catalysts and water gas, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve the problems of low loading, narrow active temperature range, and poor thermal stability of copper-based catalysts. Low loading, uniform pore distribution, improved catalytic activity and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

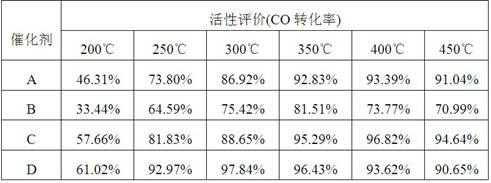

Examples

Embodiment 1

[0022] At room temperature, 4.42 g of copper acetate and 1.41 g of manganese acetate were weighed, dissolved in 400 ml of deionized water, and ultrasonically dispersed for 10 min to prepare a mixed solution. Prepare 0.5mol / L NaOH solution. Put 10 g of modified bauxite powder into a reactor equipped with a stirrer, add 300 ml of deionized water, ultrasonically disperse, and heat at a constant temperature of 80° C. to prepare a modified bauxite suspension. The mixed solution and NaOH solution were dripped into the modified bauxite suspension to keep the pH ≈ 9. After the dropwise addition was completed, the mixture was incubated for 2 hours. Filter, wash with deionized water for several times, dry at 120°C for 4h, and roast at 500°C for 6h to prepare the copper-manganese composite oxide catalyst A.

Embodiment 2

[0024] At room temperature, 3.37 g of copper nitrate and 0.58 g of manganese nitrate were weighed, dissolved in 400 ml of deionized water, and ultrasonically dispersed for 10 min to prepare a mixed solution. Prepare 0.5mol / L NaOH solution. Put 10 g of modified bauxite powder into a reactor equipped with a stirrer, add 300 ml of deionized water, ultrasonically disperse, and heat at a constant temperature of 80° C. to prepare a modified bauxite suspension. The mixed solution and NaOH solution are dripped into the modified bauxite suspension, keeping the pH ≈ 7. After the dropwise addition, the mixture was kept for 8 hours. Filter, wash with deionized water for several times, dry at 80°C for 4h, and roast at 300°C for 2h to prepare copper-manganese composite oxide catalyst B.

Embodiment 3

[0026] At room temperature, 8.04 g of copper nitrate and 2.96 g of manganese acetate were weighed, dissolved in 400 ml of deionized water, and ultrasonically dispersed for 10 min to prepare a mixed solution. Prepare 0.5mol / L KOH solution. Put 15g of modified bauxite powder into a reactor equipped with a stirrer, add 300ml of deionized water, ultrasonically disperse, and heat at a constant temperature of 80°C to prepare a modified bauxite suspension. The mixed solution and the KOH solution were dripped into the modified bauxite suspension to keep the pH ≈ 9. After the dropwise addition was completed, the mixture was incubated for 3 hours. Filter, wash with deionized water for several times, dry at 110°C for 5h, and roast at 600°C for 4h to prepare the copper-manganese composite oxide catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com