High-resistivity permanent magnetic alloy and preparing method thereof

A permanent magnet alloy, high resistivity technology, applied in permanent magnets, circuits, magnetic materials, etc., can solve the problems of low maximum magnetic energy product, working temperature limitation, etc., to increase the resistivity of magnets, reduce eddy current loss, and improve motor efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

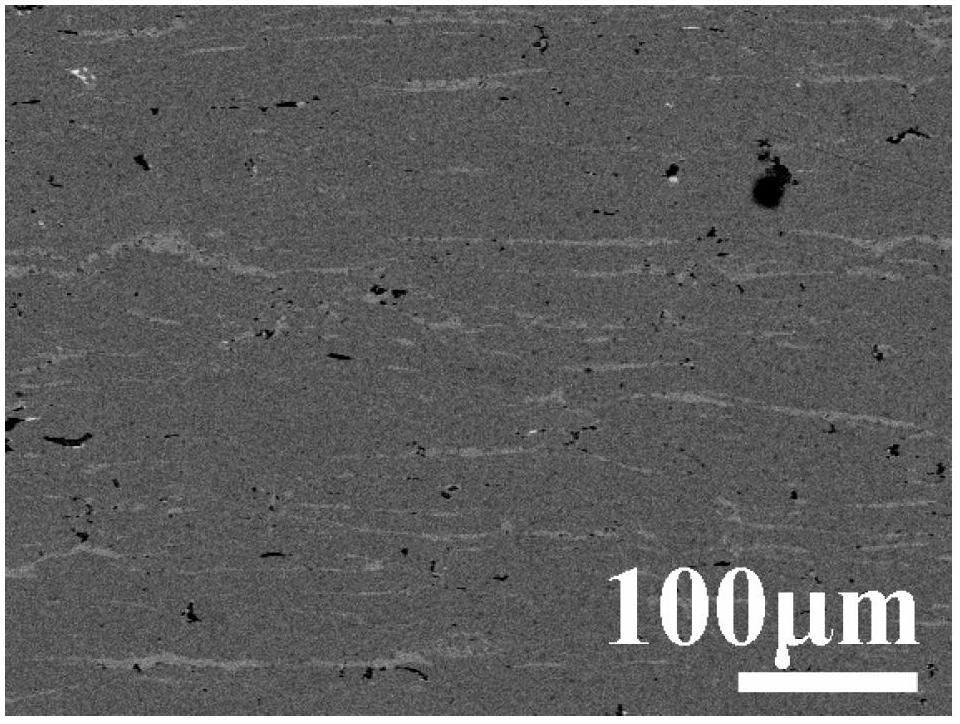

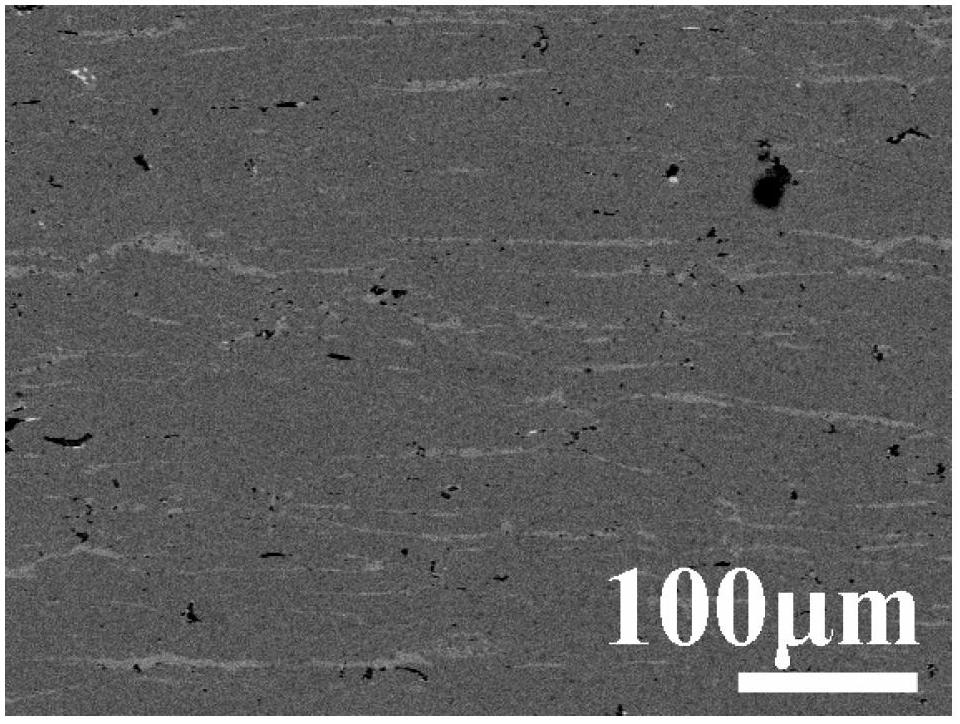

Image

Examples

Embodiment 1

[0039] The permanent magnetic alloy is prepared by the preparation method of the present invention. First, the Nd-Fe-B alloy is made into a quick-setting sheet, which is made into a micron-sized powder by hydrogen crushing and jet milling, and then CaF 2 Nano-powder is used as a solid surfactant, and its addition ratio is 10wt% of the raw material powder for air-jet milling, and a flaky powder with a surface insulating coating is obtained by high-energy ball milling, wherein the high-energy ball milling time used is 1.5 hours, and the ball-to-material ratio is 30:1 ;Compressed and formed in a magnetic field, the magnetic field used is 2T, and the pressure is 180Mpa; Finally, a high-resistivity permanent magnet alloy is obtained by hot pressing, wherein the vacuum degree of hot pressing is higher than 1.0×10 -1 Pa, the hot pressing temperature is 550°C, and the holding time is 1min.

[0040] Under the above-mentioned preparation process conditions, the resistivity of the prepar...

Embodiment 2

[0042] The permanent magnetic alloy is prepared by the preparation method of the present invention. First, the Nd-Fe-B alloy is made into a quick-setting sheet, which is made into a micron-sized powder by hydrogen crushing and jet milling, and then NdF 3 Nano-powder is used as a solid surfactant, and its addition ratio is 10wt% of the raw material powder for jet milling, and a flake powder with a surface insulating coating is obtained by high-energy ball milling, wherein the high-energy ball milling time used is 1.5 hours, and the ball-to-material ratio is 10:1 ;Compressed in a magnetic field, the magnetic field used is 2T, and the pressure is 180Mpa; Finally, a high-resistivity permanent magnet alloy is obtained by hot-pressing, wherein the vacuum degree of hot-pressing is higher than 1.0×10-1Pa, and the hot-pressing temperature is 550°C. The holding time is 1 min.

[0043] Under the above-mentioned preparation process conditions, the resistivity of the prepared high-resistiv...

Embodiment 3

[0045] The permanent magnetic alloy is prepared by the preparation method of the present invention. First, the Nd-Fe-B alloy is made into a quick-setting sheet, which is made into a micron-sized powder by hydrogen crushing and jet milling, and then DyF 3 Nano-powder is used as a solid surfactant, and its addition ratio is 10wt% of the raw material powder for jet milling, and a flake powder with a surface insulating coating is obtained by high-energy ball milling, wherein the high-energy ball milling time used is 1.5 hours, and the ball-to-material ratio is 10:1 ;Compressed in a magnetic field, the magnetic field used is 2T, and the pressure is 180Mpa; Finally, a high-resistivity permanent magnet alloy is obtained by hot-pressing, wherein the vacuum degree of hot-pressing is higher than 1.0×10-1Pa, and the hot-pressing temperature is 550°C. The holding time is 1 min.

[0046] Under the above-mentioned preparation process conditions, the resistivity of the prepared high-resistiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com