Yellow phosphorus tail gas multiple gas-source combustion power generation system

A yellow phosphorus tail gas, combustion power generation technology, applied in machinery/engine, energy efficiency improvement, waste heat treatment and other directions, can solve the problems of long-term stable operation of the system, wide distribution, small production capacity, etc. The effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

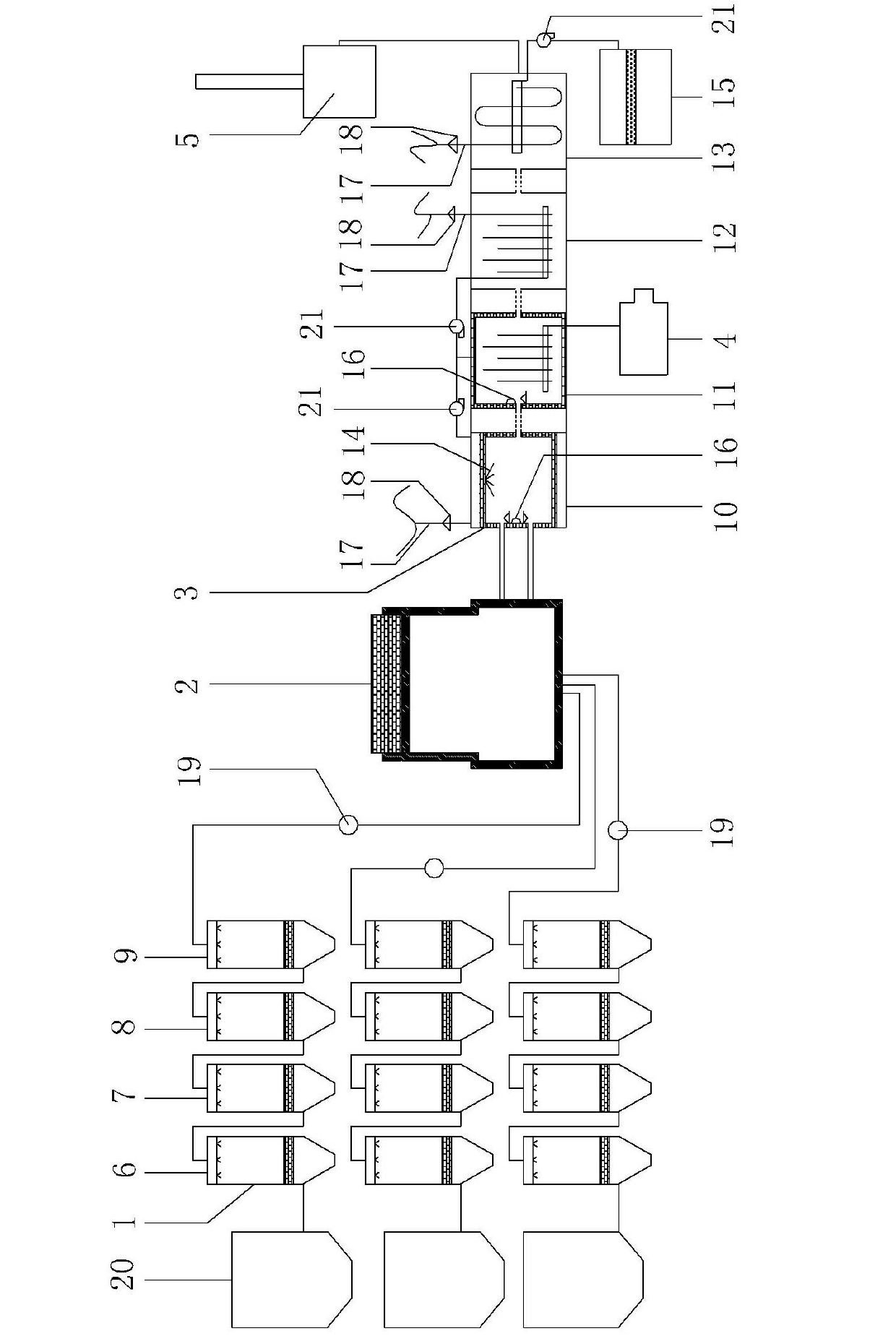

[0020] Such as figure 1 As shown, the yellow phosphorus tail gas multi-gas source combustion power generation system includes tail gas purification device 1, wet gas storage tank 2, four-stage gas boiler 3, steam turbine power generation device 4, flue gas treatment device 5 and PLC automatic control system, its characteristics The reason is: In order to save water and improve the utilization efficiency of spray water, three water washing processes and one alkali washing process are adopted for the purification of yellow phosphorus tail gas, and the spray water of the three water washing processes is recycled. The lye pH>10, the spray flow rate is 30 cubic meters per hour; the tail gas purification device 1 adopts four-stage tail gas purification towers, and the four-stage tail gas purification towers are all Pall ring packing towers, and the gas transmission pipeline and water transportation are passed between the purification towers Pipeline connection, the first-stage exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com