Wet spinning method for multi-color conductive polymer-based composite conductive fiber

A conductive polymer and composite conductive technology, applied in the direction of conjugated synthetic polymer artificial filament, wet spinning method, fiber chemical characteristics, etc., can solve the problems of low fiber conductivity and mechanical properties, monotonous color, etc., and achieve a complete color spectrum , Overcome the effect of non-abrasion resistance and obvious electrochromic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

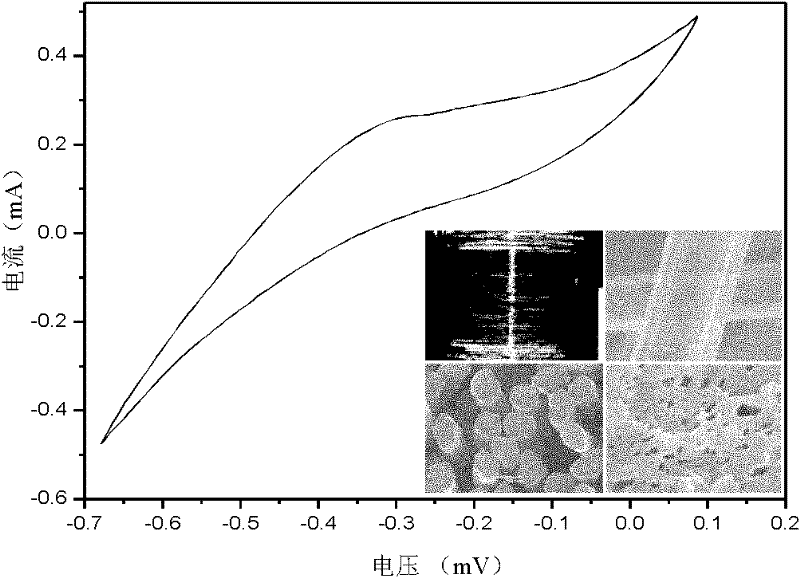

[0028] Embodiment 1, prepare a kind of PEDOT / PSS-PVA composite conductive fiber:

[0029] At -30°C, 0.5kg of EDOT monomer, 6.4kg of ammonium persulfate (oxidant), 9.6kg of polystyrene sulfonate (main dopant) and 0.25kg of fatty acid polyoxyethylene ester (emulsifier) were sequentially Add it into 10kg of distilled water, react for 24 hours, stop stirring, and filter to obtain a dark blue PEDOT / PSS dispersion emulsion;

[0030] Take 10kg of the obtained PEDOT / PSS dispersion emulsion and mix it with 2.5kg of PVA, let it stand for 3 hours, then heat the mixture at 98°C to dissolve the PVA, stand at 98°C under normal pressure for defoaming, and obtain the spinning stock solution;

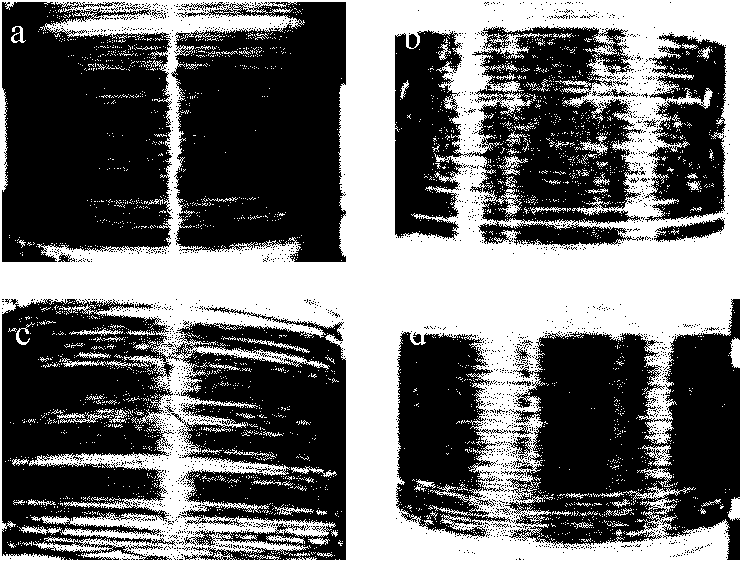

[0031]The sodium sulfate solution at 45°C close to the saturation concentration is used as the coagulation bath, the content of sodium sulfate in the bath is 410 g / l, and the 370 g / l sodium sulfate aqueous solution at 85°C is used as the wet heat stretching bath. The spinning dope is sent into the sp...

Embodiment 2

[0033] Example 2, preparing a PEDOT / PSS-PVA composite conductive fiber with fluorescent rose red as a secondary dopant:

[0034] At 10°C, 0.5kg of EDOT monomer, 8.6kg of ferric sulfate (oxidant), 19.5kg of sodium polystyrene sulfonate (main dopant), 1kg of acid red G (secondary dopant) and 0.05kg of fatty acid Add polyoxyethylene ester (emulsifier) to 20kg of distilled water successively, after reacting for 24 hours, stop stirring, and filter to obtain a dispersed emulsion in which dark purple fluorescent rose red is a secondary dopant;

[0035] Take 10kg of the obtained solution and mix it with 100kg of PVA, let it stand for 4 hours, then heat the mixture at 98°C to dissolve the PVA to obtain a viscous liquid that is evenly mixed, and stand at 98°C under normal pressure for defoaming to obtain the spinning stock solution;

[0036] The sodium sulfate aqueous solution at 45°C is used as the coagulation bath, and the sodium sulfate content in the bath is 410 g / l, and the 370 g...

Embodiment 3

[0038] Example 3, preparing a PEDOT / PSS-PVA composite conductive fiber with fluorescent yellow 184 as a secondary dopant:

[0039] At 0°C, 0.5kg of EDOT monomer, 3.2kg of sodium persulfate and 5.6kg of ferric sulfate (oxidant), 4.8kg of polystyrene sulfonic acid (main dopant) and 2.5kg of fluorescent yellow 184 (secondary dopant) agent) and 1kg polyoxyethylene laurate (emulsifier) were added to 50kg distilled water successively, after reacting for 24h, stop stirring, filter, promptly obtain the dark green dispersed emulsion that Fluorescent Yellow 184 is secondary dopant;

[0040] Take 10kg of the obtained solution and mix it with 50kg of PVA, let it stand for 6 hours, then heat the mixture at 98°C to dissolve the PVA, and obtain a viscous liquid that is evenly mixed, and stand at 98°C under normal pressure for defoaming to obtain the spinning stock solution;

[0041] The sodium sulfate aqueous solution at 45°C is used as the coagulation bath, and the sodium sulfate content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com