Water or oil expansion or extension type faucet manufacturing technology

A production process and faucet technology, which is applied to engine components, mechanical equipment, valve devices, etc., can solve the problems of low output, high rejection rate, and cannot be thrown into a mirror surface, and achieve the effect of high output, low cost, and many styles and colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is further described in detail.

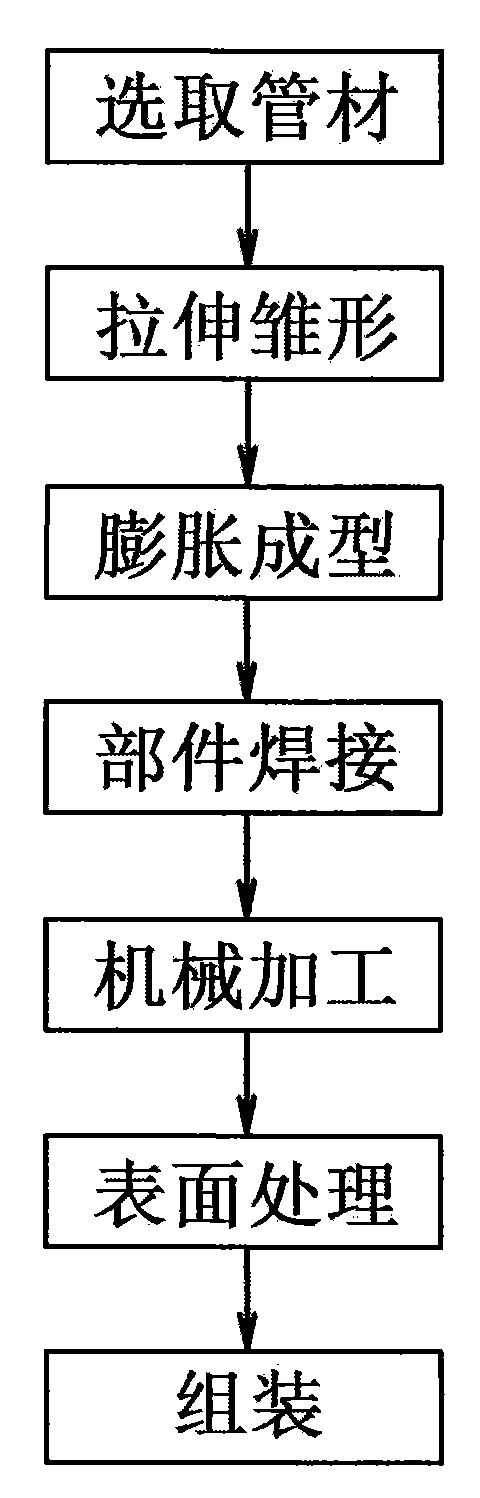

[0016] As shown in Figure 1, a faucet manufacturing process for swelling or stretching with water or oil is characterized in that it includes the following steps:

[0017] A faucet manufacturing process for swelling or stretching with water or oil, characterized in that it includes the following steps:

[0018] (1) Selection of pipe material: use 304 stainless steel pipe, 316 stainless steel pipe or copper pipe;

[0019] (2) Stretching prototype: use a hydraulic stretching machine, put the pipe into the stretching machine mold, stretch it for 18-22 seconds with a pressure of 220-270 tons, and stretch out the semi-finished product of the special-shaped tube. A 15cm-long special-shaped tube weighs 250 grams and requires 320 grams of stainless steel;

[0020] (3) Expansion molding: heat the stretched 1Scm long semi-finished product body with a weight of 250 grams and put it into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com