Preparation method of graphite alkenyl self-assembly multilayer nanometer lubricating film

A lubricating film, graphene-based technology, applied in coatings, metal material coating processes, etc., can solve the problem of not very prominent anti-wear performance, and achieve the effect of reducing friction coefficient, increasing bonding strength, and reducing surface viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, illustrate by example:

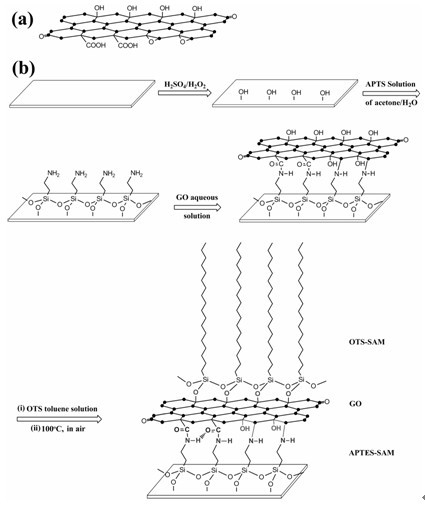

[0021] (1) Prepare a 5 mmol / L dilute solution of 3-aminopropyltriethoxysilane in a water / acetone mixture with a volume ratio of 95:5.

[0022] (2) Pre-treat the monocrystalline silicon wafers, ultrasonically clean the monocrystalline silicon wafers P(100) polished on one side in acetone solvent for 10 minutes, blow them dry with nitrogen, and place them in concentrated sulfuric acid with a volume ratio of 7:3 and 30%H 2 o 2 solution at 90°C for 0.5 hours. Take it out, clean it ultrasonically in ultrapure water and dry it with nitrogen, immerse it in the above dilute solution of 3-aminopropyltriethoxysilane, let it stand for 0.5 hours, take it out, clean it ultrasonically in ultrapure water, and blow it dry with nitrogen.

[0023] (3) Prepare a graphene oxide aqueous solution with a concentration of 0.4 mg / mL.

[0024] (4) Immediately immerse the single crystal silicon substrate assembled w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com