Cr-Ni stainless steel hot cladding surface reinforcement method

A technology of surface strengthening and stainless steel, applied in the direction of metal material coating process, coating, etc., can solve the problem of high cost of laser surface quenching and surface surfacing welding materials, difficult processing of surface thermal spraying pretreatment coating, and poor plasma cladding process. Good control and other issues, to achieve the effect of high coating performance, easy processing parameters, and dense surface strengthening points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

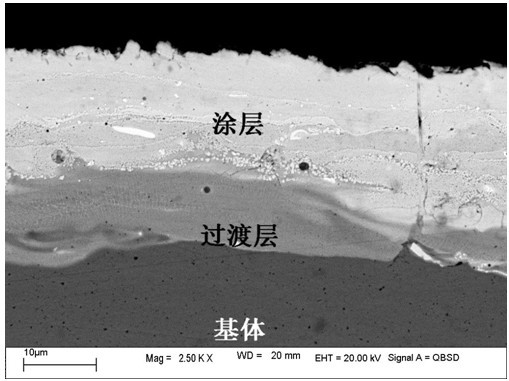

Image

Examples

Embodiment 1

[0032] Example 1: 0Cr13Ni5Mo stainless steel is used as the object of cladding treatment, and WC is selected as ceramic cemented carbide as an example. The specific process is as follows:

[0033] (1) Workpiece pretreatment: Before thermal cladding, the surface of 0Cr13Ni5Mo stainless steel workpiece is pretreated: cleaning the surface of the workpiece, removing oil, scale, etc.

[0034] (2) WC carbide electrode is used as anode, 0Cr13Ni5Mo stainless steel workpiece is used as cathode, and thermal cladding treatment is carried out. The thermal cladding gun adopts self-rotating mode, the speed is 2000r / min, and the electrode is mechanically clamped;

[0035] (3) Under the protection of inert gas argon, use thermal cladding equipment for cladding treatment, and the flow rate of argon is controlled at 5.5L / min;

[0036](4) Thermal cladding process parameters are: output power 4000W, output voltage 180V, discharge frequency 1000HZ, cladding time 1min / cm 2 . The coating can reac...

Embodiment 2

[0039] Example 2: 0Cr13Ni4Mo stainless steel is used as the object of cladding treatment, and WC is selected as ceramic cemented carbide as an example. The specific process is as follows:

[0040] (1) Workpiece pretreatment: Before thermal cladding, the surface of 0Cr13Ni4Mo stainless steel workpiece is pretreated: cleaning the surface of the workpiece, removing oil, scale, etc.

[0041] (2) Use WC cemented carbide electrode as anode and 0Cr13Ni4Mo stainless steel workpiece as cathode for thermal cladding treatment. The thermal cladding gun adopts self-rotating mode with a speed of 2200 r / min, and the electrode is mechanically clamped;

[0042] (3) Under the protection of inert gas argon, use thermal cladding equipment for cladding treatment, and the flow rate of argon is controlled at 6.0L / min;

[0043] (4) Thermal cladding process parameters are: output power 5000W, output voltage 220V, discharge frequency 1500HZ, cladding time 1.3min / cm 2 . The coating can reach 45μm, th...

Embodiment 3

[0044] Example 3: 1Cr18Ni9Ti stainless steel is used as the object of cladding treatment, and WC is selected as ceramic hard alloy as an example. The specific process is as follows:

[0045] (1) Workpiece pretreatment: Before thermal cladding, the surface of 1Cr18Ni9Ti stainless steel workpiece is pretreated: cleaning the surface of the workpiece, removing oil, scale, etc.

[0046] (2) Use WC cemented carbide electrode as anode and 1Cr18Ni9Ti stainless steel workpiece as cathode for thermal cladding treatment. The thermal cladding gun adopts self-rotating mode with a speed of 2500r / min, and the electrode is mechanically clamped;

[0047] (3) Under the protection of inert gas argon, use thermal cladding equipment for cladding treatment, and the flow rate of argon is controlled at 6.5L / min;

[0048] (4) Thermal cladding process parameters are: output power 6000W, output voltage 260V, discharge frequency 2400HZ, cladding time 2min / cm 2 . The coating can reach 50μm, the coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com