Method for manufacturing sponge iron

A manufacturing method and technology of sponge iron, applied in the direction of fluidized bed furnace, etc., can solve the problems of low production efficiency, low product density, uneven reaction, etc., and achieve the effect of reducing metal recovery rate, reducing material loss, and prolonging smelting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

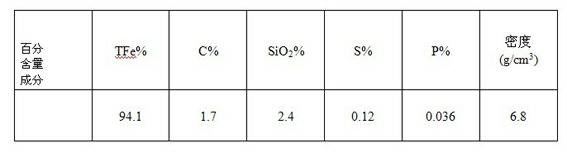

Embodiment 1

[0011] Dry iron concentrate powder, blue charcoal powder, lime powder and ferrosilicon powder respectively and crush them to 50 meshes, mix them according to weight percentage 1: 0.2: 0.1: 0.05, put them into a rotary kiln, heat up to 1150°C for 80 minutes, Keep the temperature out of the kiln for 8 hours and take out the sponge iron.

[0012]

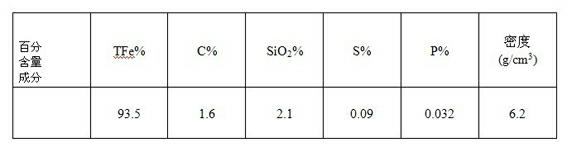

Embodiment 2

[0014] Dry and crush iron-containing dust, blue carbon powder, lime powder, and ferrosilicon powder to 80 meshes, mix them according to weight percentage 1: 0.4: 0.2: 0.1, put them into a rotary kiln, and heat up to 1200°C for 100 minutes. Keep the temperature out of the kiln for 10 hours and take out the sponge iron.

[0015]

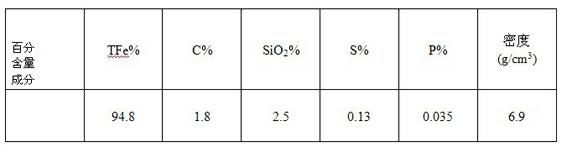

Embodiment 3

[0017] Dry the gravity dust removal powder, blue charcoal powder, lime powder and ferrosilicon powder respectively, crush them to 100 mesh, mix them according to the weight percentage 1: 0.6: 0.3: 0.15, put them into the rotary kiln, raise the temperature for 120 minutes to 1250°C, and keep the temperature constant 12 hours out of the kiln to take out the sponge iron.

[0018]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com