Method for preparing biological oil-based syngas by utilizing biological oil produced by thermal cracking of agricultural and forestry wastes to gasify

An agricultural and forestry waste, thermal cracking technology, applied in the petroleum industry, the manufacture of combustible gas, the production of bulk chemicals, etc., can solve problems such as pollution and waste of resources, reduce CO2 content, improve yield and quality, and solve coking technology puzzle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

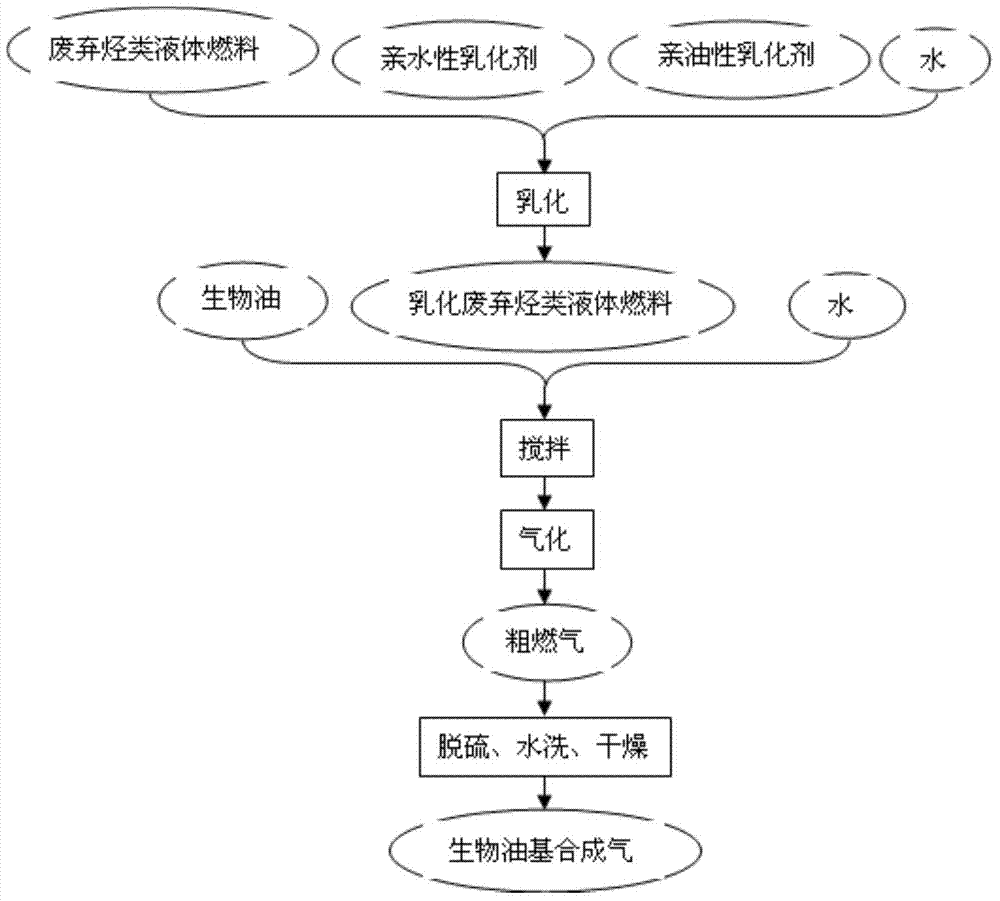

[0026] Example 1: Preparation of Syngas by Mixed Gasification of Bio-oil and Waste Engine Oil

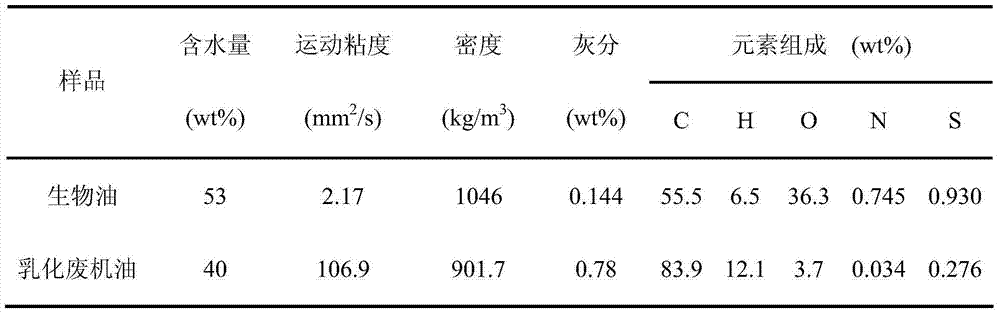

[0027] use figure 1 In the process flow shown, the dehydrated waste engine oil (H 2 (0≤0.5wt%), slowly add 8wt% Tween 60 and 4wt% mixture of Span 60 and Span 80, add 40wt% water at the same time, emulsify at 80°C for 5min to obtain emulsified waste engine oil. Bio-oil obtained from rapid pyrolysis of waste corn stalks (refer to the literature for its preparation [Zhu Xifeng, Guo Tao, Lu Qiang, Guo Qingxiang. Experiments on atomization combustion characteristics of bio-oil, Journal of University of Science and Technology of China, 2005, 35(6): 856-860 ] published preparation method) and emulsified waste engine oil as raw materials for gasification, its physical parameters and elemental composition are shown in Table 1.

[0028] Table 1 Physical parameters and elemental composition of bio-oil and emulsified waste engine oil

[0029]

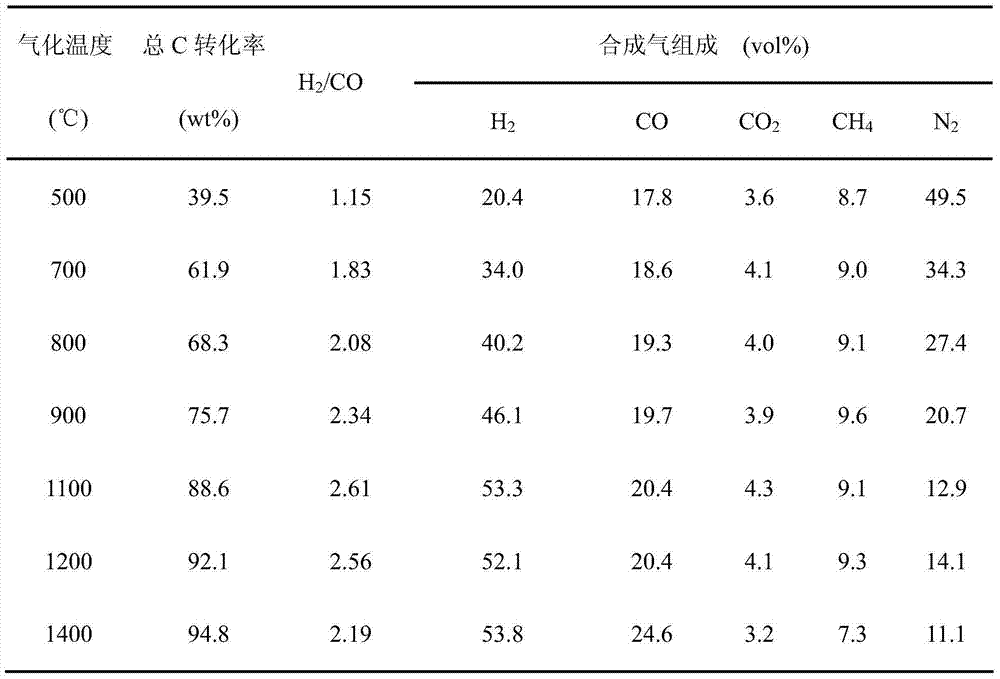

[0030] Add 20wt% and 30wt% of water to the b...

Embodiment 2

[0036] Example 2 Preparation of Syngas by Mixed Gasification of Bio-oil and Waste Diesel Oil

[0037] use figure 1 The process flow shown, under the action of strong stirring, waste diesel oil (H 2 (0≤0.1wt%), slowly add 1wt% Tween 80 and 1wt% Span 80, and add 10wt% water at the same time, and emulsify at 10°C for 60 minutes to prepare emulsified waste diesel oil. Bio-oil obtained from rapid pyrolysis of waste rice husks (refer to the literature for its preparation [Zhu Xifeng, Guo Tao, Lu Qiang, Guo Qingxiang. Experiments on atomization combustion characteristics of bio-oil, Journal of University of Science and Technology of China, 2005, 35(6): 856-860 ] published preparation method) and emulsified waste diesel oil as gasification raw materials, its physical parameters and elemental composition are shown in Table 4.

[0038] Table 4 Physical parameters and elemental composition of bio-oil and emulsified waste diesel

[0039]

[0040]

[0041] Add 10wt% and 40wt% wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com