Process for preparing methane by utilizing coke oven gas

A coke oven gas and process technology, which is applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of large consumption of coke oven gas, difficult catalyst recovery, and difficulty in generating gas from the reaction, and achieves high methane output, low load, easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

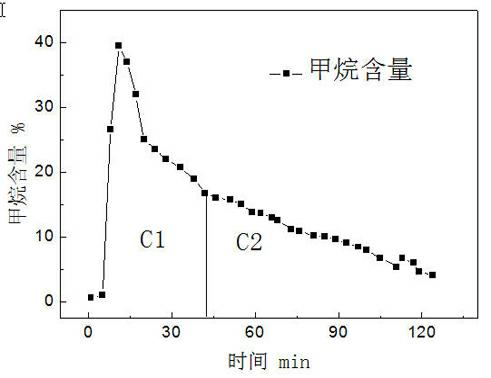

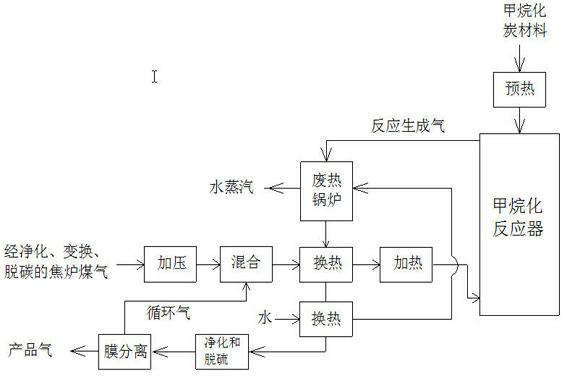

Embodiment 1

[0019] Using the coke oven gas produced by the 1 million tons coking plant as the gas source, the coke oven gas is first purified to remove dust and tar, and then CO conversion and decarbonization are carried out. The composition and volume content of decarburized coke oven gas are: H 2 Content 70%, CH 4 Content 26%, C m H n (Other alkanes except methane) content 3.5%, CO content 0.2%, CO 2 Content 0.1%, total sulfur mass content 6g / Nm 3 . The decarburized coke oven gas is pressurized to 6MPa, and mixed with the circulating gas at a volume ratio of 1:1.5 to obtain a mixed raw material gas. The volume content of methane in the mixed raw gas is 10.4%. The mixed raw material gas first exchanges heat with the reaction product gas, then is heated to 550°C, and finally sent to the methanation reactor; the elemental analysis shows that the oxygen content of the methanation carbon material without water and ash is 5.8%. The mass content of hydrogen is 4.7% and the mass content of carbo...

Embodiment 2

[0021] Taking the coke oven gas produced by the 1 million tons coking plant as the gas source, the composition and volume content of the coke oven gas after purification, CO conversion and decarbonization are: H 2 Content 65%, CH 4 Content 28%, C m H n 3% content, 0.1% CO content, CO 2 Content 0.2%, total sulfur content 3g / Nm 3 gas. Then pressurize the decarburized gas to 7 MPa, and mix it with the circulating gas in a volume ratio of 1:2 to obtain a mixed raw material gas. The volume content of methane in the mixed raw gas is 9.3%. The mixed raw material gas is heated to 600°C first, and then sent from the bottom of the methanation reactor to the methanation reactor; the selected methanation carbon material has an anhydrous and ash-free oxygen element mass content of 6.5%, and hydrogen element The mass content is 4.9%, and the carbon content is 85.3% (obtained by elemental analysis). The methanation carbon material heated to 450°C is fed into the methanation reactor at a feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com