Preparation method of medium/high-viscosity alpha,omega-dihydroxypolydimethylsiloxane

A hydroxyl polydimethylsiloxane and viscosity technology, applied in the field of organic compound preparation, can solve problems such as complicated steps, and achieve the effects of short reaction time, high production efficiency and less ring content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

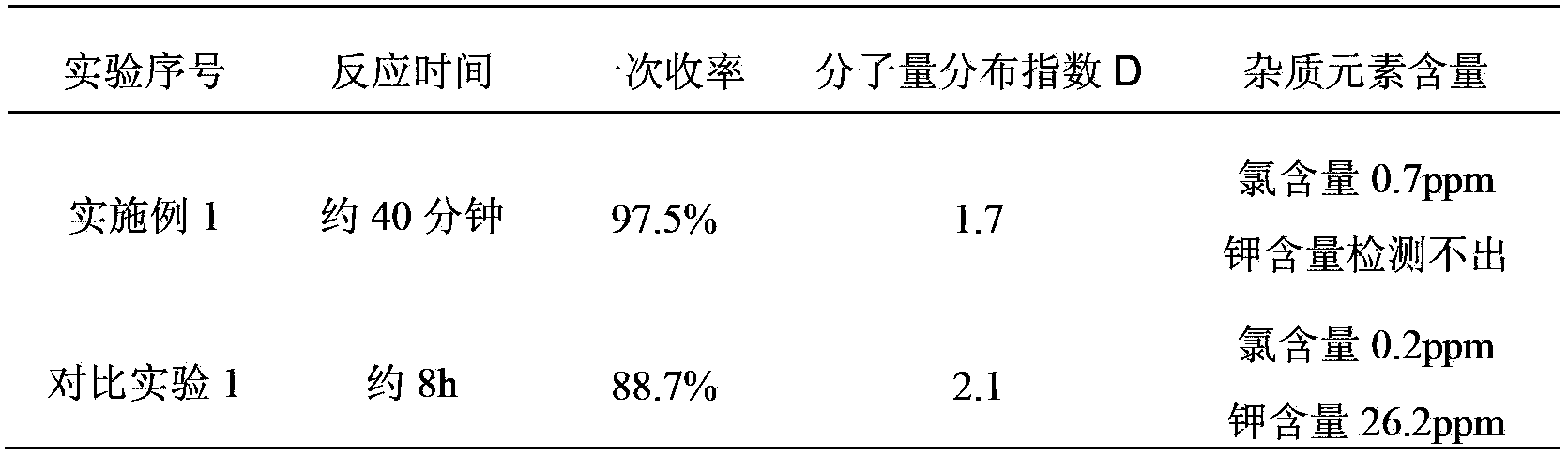

Examples

Embodiment 1

[0027] Embodiment 1: The method for preparing medium and high viscosity α, ω-dihydroxy polydimethylsiloxane, the steps are as follows:

[0028] (1) Take 1000g of dimethyldichlorosilane hydrolyzate (Shandong Dongyue Organic Silicon Material Co., Ltd.), whose viscosity is tested to be 31mPa·s, add 0.5wt% 4A molecular sieve (Nanjing Jumao Technology Co., Ltd.) and dry for 8h Afterwards, the hydrolyzate obtained by filtration was clear and transparent. Transfer the hydrolyzate to a round-bottomed flask, install a 30cm long thorn type fractionation column on the round-bottom flask, heat the hydrolyzate to 100°C to remove the rings under reduced pressure, and the total rings of the received rings (D 3 ~D 8 ) content was measured on gas chromatography to reach 99.988%, of which the total chlorine content was 0.3ppm. The product remaining in the round bottom flask has a viscosity of 71.2mPa·s, a total chlorine content of 0.9ppm, and a volatile matter of 2.7%, which is low-viscosity ...

Embodiment 2

[0035] Embodiment 2: The method for preparing medium and high viscosity α, ω-dihydroxypolydimethylsiloxane, the steps are as follows:

[0036](1) Dihydroxypolydimethylsiloxane was prepared by using dimethyldichlorosilane hydrolyzate, as in step (1) of Example 1, except that the added drying reagent was changed to anhydrous calcium chloride.

[0037] (2) Take 500g of dihydroxypolydimethylsiloxane at 71.2mPa·s and put it into a round bottom flask, reduce the pressure to -0.090MPa, rapidly raise the temperature to 180°C, observe the online viscosity change on the stirrer, 1 hour 20 When the viscosity reaches 8000mPa·s within 1 minute, stop heating immediately and add 30g of carbon dioxide dry ice to rapidly cool it down to 120°C, and then take a sample for analysis. The product has a viscosity of 8800mPa·s, a total chlorine content of 0.9ppm, a volatile matter of 2.5%, and a yield of 98.1%. .

Embodiment 3

[0038] Embodiment 3: the method for preparing medium and high viscosity α, ω-dihydroxy polydimethylsiloxane, the steps are as follows:

[0039] Take dihydroxypolydimethylsiloxane with a viscosity of 22.5mPa·s, depressurize it to -0.080MPa, raise the temperature to 180°C, observe the online viscosity change on the stirrer, stop heating immediately when the viscosity reaches 1400mPa·s after 40 minutes And add 25g of carbon dioxide dry ice to make it cool down to 100°C rapidly, and then take a sample analysis, the product has a viscosity of 1520mPa·s, a volatile matter of 2.7%, and a yield of 92.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com