A method for separating nano-aluminum powders of different particle sizes

A technology of nano-aluminum powder and particle size, which is applied in the direction of solid separation, chemical instruments and methods, and separation of solids from solids with airflow, which can solve the problems of expensive, bulky separation equipment, and complicated separation procedures, and achieve less loss , good separation effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

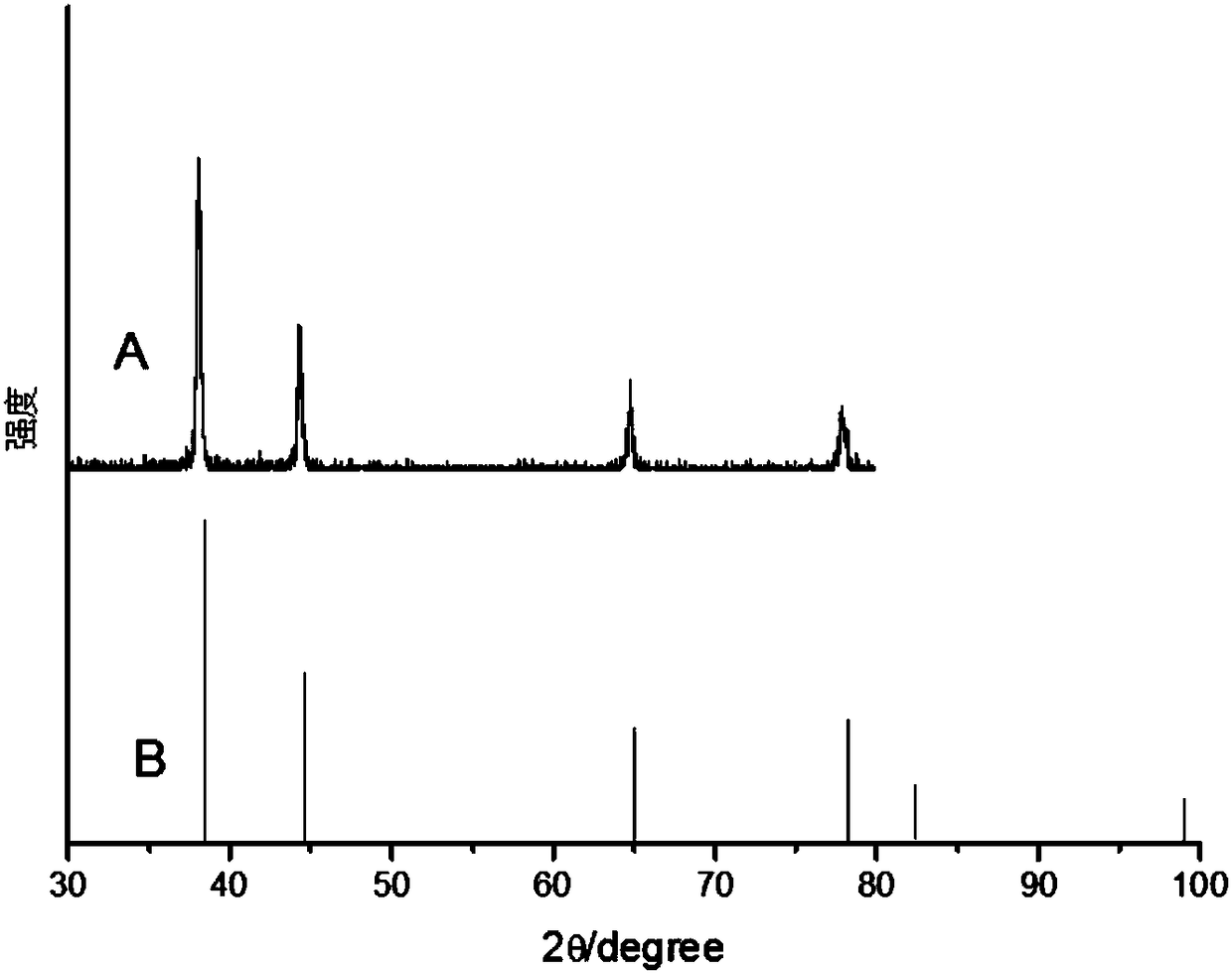

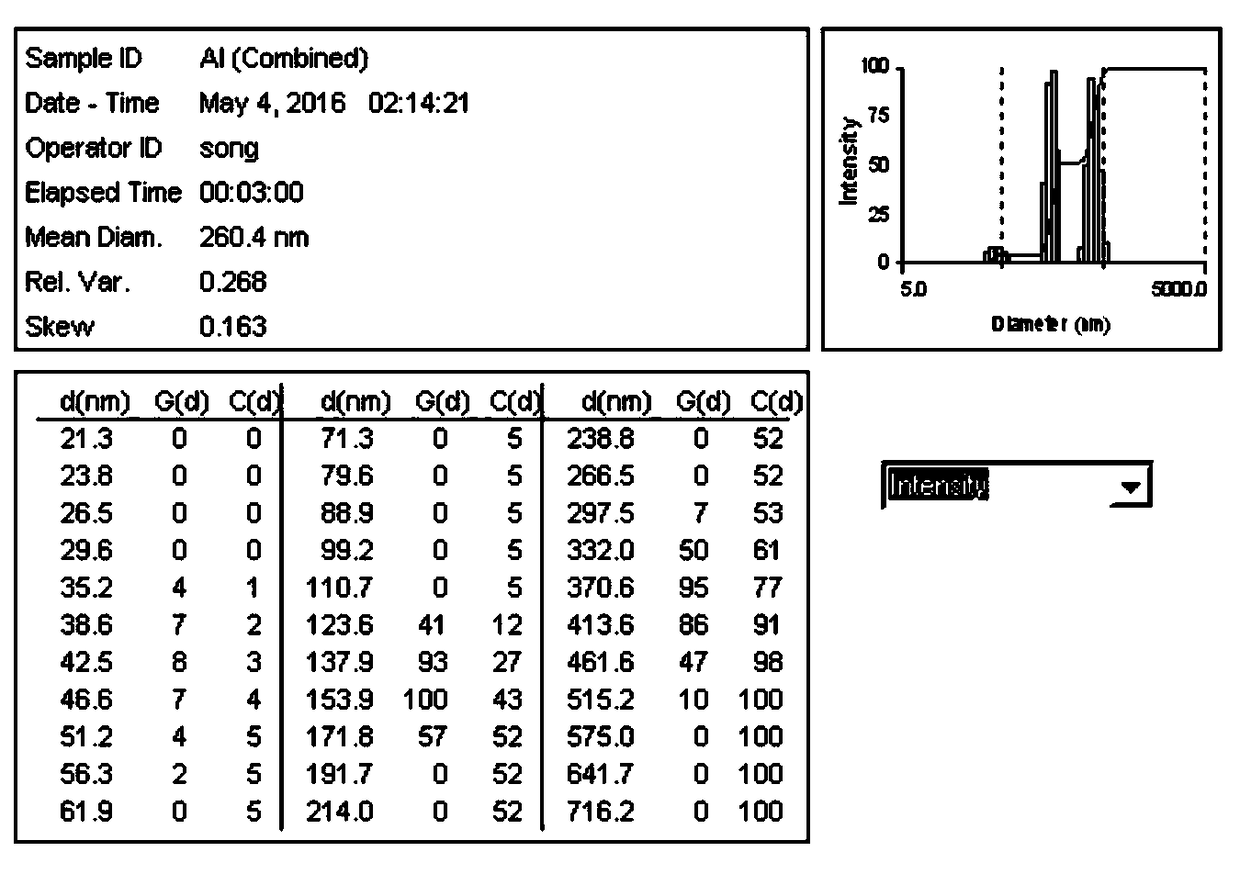

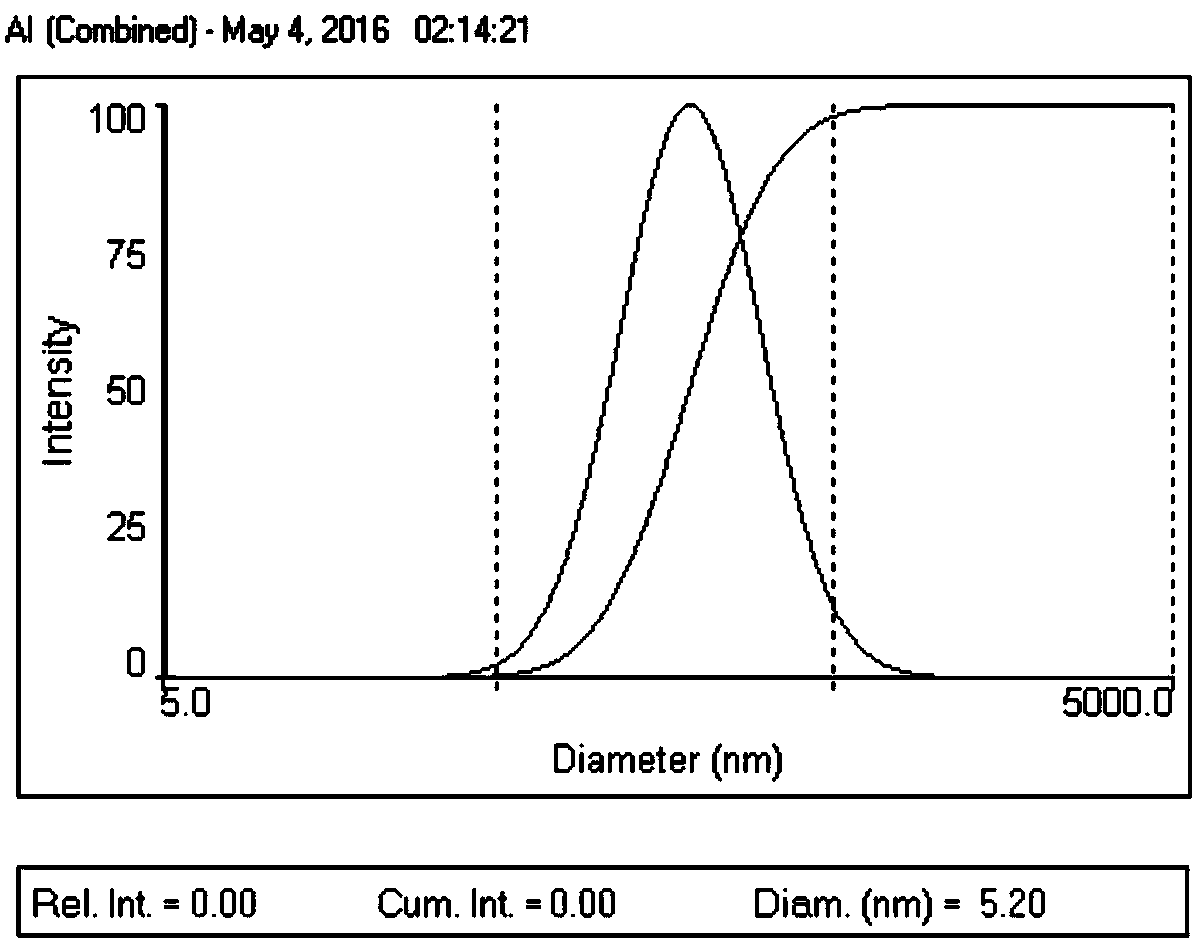

Method used

Image

Examples

Embodiment 1

[0093] Take 1g of the nano-aluminum powder prepared in (1), disperse in 30mL of absolute ethanol, oscillate ultrasonically for 4 hours, put it into a centrifuge tube after the temperature of the beaker has dropped, centrifuge at 4000rpm for 5 minutes, pour the upper liquid Put it into a beaker and mark it as No. 1, and the nano-aluminum powder at the bottom of the sedimentation centrifuge tube is used in Example 2.

Embodiment 2

[0095] Add 30 mL of dispersant absolute ethanol to the nano-aluminum powder deposited at the bottom of the centrifuge tube in Example 1, after ultrasonic oscillation for 10 minutes, centrifuge at a speed of 3500 rpm for 5 minutes, pour the upper liquid into a beaker and mark it as No. 2, The upper suspension was weighed, and the nano-aluminum powder deposited at the bottom of the centrifuge tube was used in Example 3.

Embodiment 3~8

[0097] Repeat Example 2, the only difference is that the rotational speed of centrifugation is 3000rpm, 2500rpm, 2000rpm, 1500rpm, 1000rpm, 500rpm respectively, and the obtained components are respectively marked as No. 3, No. 4, No. 5, No. 6, No. 7 and No. 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com